The automotive industry in the world is developing fast due to the need for lightweight cars, better fuel efficiency, lower emissions, and high-performance parts. Alumiinin painevalu has emerged as one of the most important manufacturing processes, which has been amazingly supportive of this transformation. In the electric car design, aluminum die-cast components are crucial in the modern automotive design, including engine housings and transmission cases, as well as structural components of the car.

The selection of an appropriate automotive parts aluminum casting supplier is no longer an easy-purchasing choice. It is a strategic alliance that influences the quality of products, production efficiency, cost control, and business success in the long run.

This paper describes the steps involved in identifying the most optimal aluminum die-casting supplier, as well as identifies some of the leading manufacturers of aluminum die-casting auto parts in China and globally.

Sisällysluettelo

ToggleWhy Automotive Manufacturing Requires Aluminum Die Casting

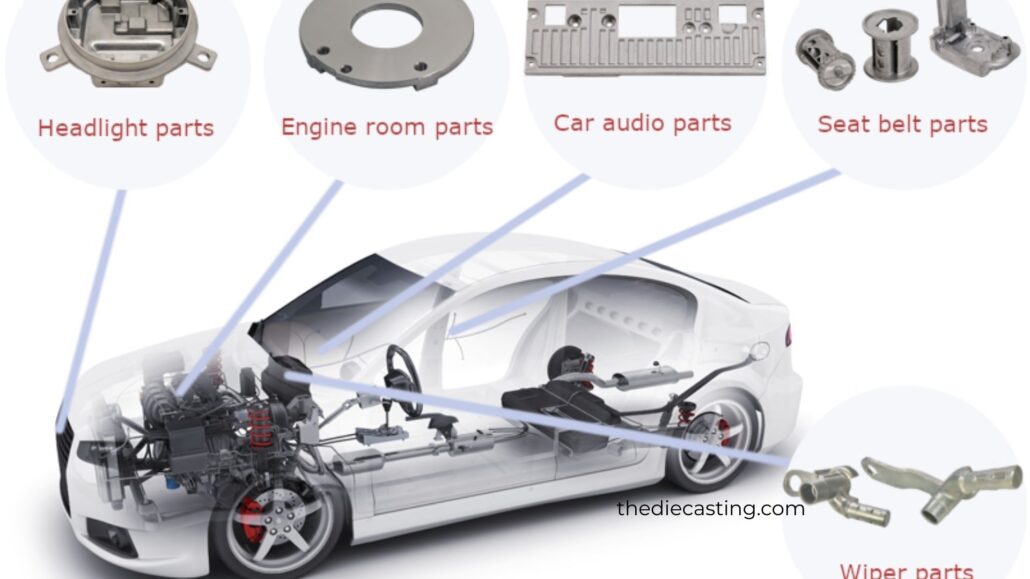

Through alumiinin painevalu, manufacturers are able to develop complicated, high-precision components at massive volumes with high surface finish and dimensional accuracy. Aluminum has a better strength-to-weight ratio, resistance to corrosion, and thermal conductivity than conventional materials, it is the perfect material to be used in automobiles.

Alumiinin painevalu is becoming even more significant with the emergence of electric vehicles. Die-casting technology is important in battery casings, motor frames, inverter casings, and massive structural parts. With the increased complexity of the automotive designs, the suppliers have to provide casting services along with the engineering services, machining, surface finishing, and quality control.

Essential Factors to be Considered When Selecting an Aluminum Casting Supplier

Car and Automotive Knowledge and Experience

The experience of the aluminum die casting supplier in automotive die casting is one of the first factors that should be considered. Car parts have to be of high safety, durability, and compliance with regulations. A supplier who has been long term in experience in automotive projects knows the choice of materials, control of tolerances, and process stability.

The suppliers who have engaged in partnership with automotive OEMs, with Tier-1 or Tier-2 suppliers, tend to produce steady quality and handle complicated production specifications.

Production Facilities and Resources

A trusted aluminum die-casting company must possess up-to-date production facilities such as high-pressure die-casting machines of different tonnages, CNC machining centres, and surface finishing. It is a great strength to be able to deal with small precision castings as well as large structural castings.

Automation, robotics, and digital monitoring are other technologies that are also frequently used by advanced suppliers to attain repeatability and minimize defects in mass production.

Quality Control and Certifications

In car production, quality control plays a key role. The most effective suppliers have been developed on internationally recognized systems of quality like ISO 9001, IATF 16949 (previously TS 16949), and ISO 14001. These certifications are an indication of quality management, process control, and environmental responsibility.

The inspections are also checked in-house by CMM machines, X-ray tests, spectrometers, and pressure leak testing systems, which also ensure that the product has high reliability.

Engineering Customisation and Support

Automotive projects are normally customized as opposed to off-the-shelf products. An effective supplier of aluminum die-casting must be able to provide engineering services to the initial design phase, such as design of the mould, optimization of materials, and design-for-manufacturing (DFM) analysis.

Aluminum die casting suppliers are the ones where customers can find prototyping, rapid tooling, and design validation services, which would reduce the development time and eliminate expensive redesigns.

International Supply Chain and Delivery Performance

- Aluminum automobile parts supply chains are international.

- An effective supplier must be able to export to foreign markets and be efficient in logistics.

- Long-term cooperation presupposes clear communication.

- English-speaking project managers, and stable after-sales support.

World and China Leaders of Auto Parts Suppliers: Aluminum Die Casting

CNM Tech Co., Ltd

Yrityksen yleiskatsaus

CNM Tech Co., Ltd. is an experienced manufacturer of aluminum die-casting auto parts with over 20 years of working experience in the industry, based in Dongguan, China. The firm deals with aluminum, magnesium, and sinkkivaluCNC-työstö, pintakäsittely ja kokoonpano.

CNM Tech manufactures components of aluminum, zinc, and some magnesium that weigh not more than 12 kg, 2 kg, and others, respectively. Its vertically integrated production system includes sourcing of raw materials, tooling, casting, machining, finishing, and final packaging.

Miksi valita CNM Tech

CNM Tech has the advantage of end-to-end capabilities of manufacturing. The company has retained tooling, machining, and surface finishing, resulting in complete control of quality and lead times. The company works on the basis of ISO 9001, TS 16949, and ISO 14001 quality systems, which guarantee high-quality production with automotive standards.

CNM Tech provides aluminum die-casting auto parts at competitive prices; therefore, it offers its customers a reliable partner in supplying high-precision parts worldwide.

Toimialat, joita palvellaan

CNM Tech also deals with the medical equipment, home appliances, LED electronics, power tools, and mechanical equipment segments in the automotive industry.

Vilpitön tekniikka

Yrityksen yleiskatsaus

Vilpitön tekniikka is a full-service manufacturing firm with its headquarters located in Dongguan, China, and was established in 2005. The company is a specialist in die castings in aluminum, plastic injection molding, CNC machining, silicone rubber components, and entire assembly solutions.

Sincere Tech offers small-tolerance parts to the high-pressure industries with highly modernized production equipment like CNC machines, EDM systems, and CMM inspection equipment.

Why Choose Sincere Tech

Sincere Tech has a real one-stop point of manufacture. All processes are handled in a single location, starting with product designing, prototyping, mould making, die casting, machining, and packaging. This combined solution will minimize the risk of coordination and enhance efficiency in production.

The company has excellent project management, English-speaking abilities, and experience in delivering world domination, making it a good partner to automotive customers who want consistency and cost-efficient production.

Toimialat, joita palvellaan

Sincere Tech is a manufacturer of die-cast parts made of aluminum and sold to automotive manufacturers, electronic manufacturers, medical equipment manufacturers, home appliances manufacturers, and industrial machinery manufacturers.

GC Precision Mould Co., Ltd.

Yrityksen yleiskatsaus

Aludiecasting, the Chinese company is called GC Precision Mould Co. Ltd., a major manufacturer of auto parts under die-casting of aluminum, and is based in Dongguan, Guangdong, China. The company is over 20 years old, ISO 9001 certified, and it is based in North America, Europe, and Asia, serving its customers.

GC Precision Mould deals with aluminum alloys like ADC12, A380, A360, 6061, and 6063, zinc, magnesium, and bronze. Its production has high-pressure die-casting machines that range between 120 and 1650 tonnes and gravity casting of parts up to 50kg.

Reasons to select GC Precision Mould

The full range of services of GC Precision Mould includes the design and prototyping of moulds, casting, CNC machining, surface finishing, and plastic injection moulding. Modern equipment, qualified engineering staff, and high-quality control provide the company with constant and cost-effective automotive parts.

High precision parts as well as large structural components are also handled by it, which makes it a perfect partner on automotive and industrial projects.

Toimialat, joita palvellaan

GC Precision Mould is the manufacturer of aluminum die-cast parts used in the automotive, aerospace, marine, electronics, telecommunications, lighting, medical equipment, robotics, machinery, and watercraft sectors.

Buhler Group

Yrityksen yleiskatsaus

Buhler Group is a technology leader that specializes in manufacturing solutions based on advanced technology and is located in Uzwil, Switzerland. Buhler has a significant contribution to the development of the modern die-casting technologies and has more than 13, 000 workers who work in more than 140 countries.

The company also spends intensely on research and development, with its special consideration on ultra-large structural components of aluminium and sustainable manufacturing processes.

Why Choose Buhler Group

Buhler has been known globally as an innovative, reliable, and long-term technological leader. Its die-casting applications serve automobile manufacturers that manufacture large, complex assemblies that are highly efficient and less harmful to the environment.

The global service network offered by Buhler provides quick support, training, and maintenance services, which have made the company an impeccable technology partner in automotive foundries.

Toimialat, joita palvellaan

Buhler services such as automotive, battery production, electronics, packaging, optics, and advanced materials, as well as food and grain processing industries.

Italpresse Gauss

Yrityksen yleiskatsaus

Italpresse Gauss is an Italian technology firm that was founded in 1969 and specializes in die-casting machines and automated production systems made of aluminum. The company is more than 50 years old and is a maker of high-pressure, gravity, and low-pressure die-casting solutions.

The company has a technology centre in Italy and has a presence of great magnitude in China, allowing quick local service and international project assistance.

Why Choose Italpresse Gauss

Italpresse Gauss is reputed to have modular, scalable, and customised die-casting solutions. Unlike other companies, the company produces high-performance machines, that is, large structural casting systems, which are energy efficient and can last longer.

Its worldwide spare parts, retrofit, and digital service network guarantee full uptime to automotive production lines.

Toimialat, joita palvellaan

Italpresse Gauss serves the needs of automotive, aerospace, electronics, and industrial machinery producers that need high precision aluminum die-casting solutions.

Get It Made

Yrityksen yleiskatsaus

Get It Made is a company in the United Kingdom that was founded in 2011 to offer services in the field of aluminum die castings, CNC machining, injection moulding, extrusion, 3D printing, and sheet metal fabrication. The company is guided by ISO 9001 certification and partners with reputable partners in the UK, China, and the Czech Republic.

Why Choose Get It Made

Get It Made provides a direct customer focus that gives direct engineering support, a quick response rate, and no hidden charges. By taking care of logistics, VAT, and import duties, the company makes international manufacturing as easy as developing products, which enables its customers to invest their energy in the development of the products.

The agile organization and international manufacturing base of the company make it a stable supplier of aluminum die-casting automobile parts, both in prototyping and manufacturing.

Toimialat, joita palvellaan

Get It Made provides services to aerospace, medical, green energy, robotics, research and development, and automotive engineering.

Päätelmä

Choosing an ideal supplier of automotive parts in the form of alumiinin painevalu is a very serious decision that will influence the quality of the products, efficiency of production, and competitiveness in the long run. The market leaders like CNM Tech, Sincere Tech, GC Precision Mould, Buhler Group, Italpresse Gauss, and Get It Made have their own advantages, including affordable production and high-tech automation, international networks of services, and engineering innovations.

Chinese producers have good technical skills, low prices, and large production capacity, whereas the European and United Kingdom companies are stronger in terms of inventive, sustainable, and highly automated. This combination of suppliers creates an ecosystem for the future of the automotive manufacturing industry around the world.

Through a wise consideration of experience, manufacturing prowess, quality systems, customization, and the assistance offered in any region of the world, the businesses will be able to establish trustful relationships that can lessen the risk, enhance their performance, and contribute to the long-term development in the automotive industry.

UKK

What does it mean by aluminum die casting in the manufacture of auto parts?

Alumiinin painevalu is a production process where molten aluminum is forced into high-pressure steel molds to make lightweight, strong, and highly precise automotive parts.

What is the logic of picking a Chinese supplier of aluminium die-casting?

Chinese suppliers are the best in the world in terms of aluminum die casting due to their competitive prices and high production capacity, latest machinery, and quality systems that are ISO certified.

What do the suppliers do to guarantee quality in the aluminium die casting?

The best suppliers are also ISO and automotive quality compliance, modern inspection tools, and CNC machining and surface finishing to guarantee precision and lifespan.

In which industries are die-cast aluminium parts of aluminium most in use?

Also used in aerospace, medical equipment, electronics, lighting, and industrial machinery, in addition to automotive, aluminum die-cast parts are also common.

What should be considered when selecting a supplier?

Some of them are experience, certifications, production capacity, the ability to customize products, support delivery globally, and quality customer service.