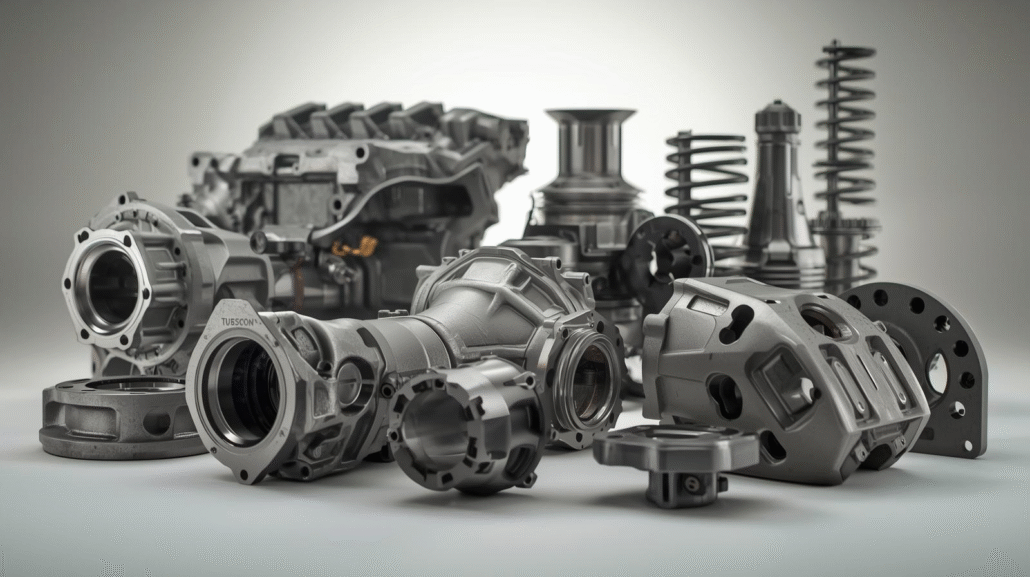

Aluminum die casting is now one of the surest and most economical production procedures in the United States of America, particularly to manufacturers that require robustness, longevity and precision. This is done by high pressure injection of molten aluminum into steel castings and this produces parts which are not only lightweight but also dimensionally accurate and durable. It is this strength and low weight that makes aluminum die casting the material of choice in the automotive and aerospace industry, electronics, industrial machineries, and consumer goods.

The U.S market boasts of some of the most established alumiinin painevalu industry worldwide in the form of large scale manufacturers with global presence to small and specialized firms, specializing in custom parts and niche applications. These firms are very crucial in the sustenance of the key industry by supplying such segments of the industry as engine blocks, transmission housings, electronic enclosures, and structural parts. The U.S. based manufacturers have earned their reputation of reliability and innovative products in the world through their high quality technologies, certification and focus on quality products.

The trend in the last few years has seen a massive surge in demand of die-cast aluminum parts because of the recent developments in lightweighting of vehicles, the production of electric vehicles, and the drive to manufacture energy efficiently. American firms are embracing automation, sustainable castings, and superior alloys so as to achieve high results to meet these requirements.

This article lists some of the best aluminum die casting manufacturers in the USA and their achievements, potential, and contributions to the contemporary industry. It does not matter whether you are getting parts to perform a large-scale manufacturing process or a highly-technical application, these manufacturers are the embodiment of the finest American technology in aluminum die casting.

Sisällysluettelo

ToggleWhat Is Aluminum Die Casting?

Alumiinin painevalu is a production technique where high pressure on a molten aluminum is forced into a steel mold also referred to as a die. When the metal cools and solidifies the mold is opened and the completed part is ejected. This is the process with the help of which the manufacturers can create strong, light and highly detailed components with high level of dimensional accuracy and smooth surface finishes.

The fact that aluminum die casting can produce complex shapes that would otherwise be challenging or costly to produce using other manufacturing processes is the key benefit. It finds extensive application in the manufacture of such parts as engine blocks, transmission housings, electronic enclosures, heat sinks and structural components.

The Aluminum Die Casting has several major advantages:

- Light, but tough – Aluminum is a strong material that is light and at the same time durable, and this makes it the best component in automotive and aerospace applications.

- High accuracy – Die casting guarantees quality consistency, tight tolerances and repetition of mass production.

- High thermal and electrical conductivity – Can be used in electronics and in applications that deal with heat management.

- Corrosion resistance – Aluminum is a naturally corrosion-resistant material, which contributes to the increased products life.

- Economy at large quantity – After the making of the mold, it is possible to produce thousands of the same parts within a short time saving cost.

Thanks to such strengths, aluminum die casting has emerged as a better alternative in industries, which require dependable and efficient components of high-quality to match its technical and economical necessities.

Top USA Aluminum Die Casting Companies

1. Dynacast International

Dynacast International has been one of the best known companies in the area of precision die casting globally. The company has decades of experience in the production of small, complex components with the use of aluminum, zinc and magnesium alloys. They are good at producing components that have stringent tolerances and that have complex features, which are needed by the automotive, consumer electronics, telecommunications, and medical devices industries. Being global also means that Dynacast is able to serve small businesses and multinational companies with the flexibility, innovations and quality that do not vary among projects.

2. Pace Industries

Having become the largest die casting companies in North America, Pace industries have established a good reputation of offering to offer solutions in totality. Their service ranges include designs and engineering support, die castings, machining, surface finishing and final assembly; they have been providing a one-stop solution to clients in the automotive, industrial and consumer industries. High-volume projects and custom projects can be dealt with because of the scale of their operations. Pace also follows the culture of putting money in the modern technology and sustainable practices such that they can be able to remain competitive in the rapidly changing industry.

3. Ryobi Die Casting (USA), Inc.

Ryobi is a renowned brand in the world die casting segment, and it has a major presence in the United States. Their operations in the U.S. are centered on medium to large scale aluminum die cast components, majorly to the automotive sector. Ryobi manufactures engine block, transmission housing, and structural parts that they need to be durable and precise. The firm has utilized cutting edge technology and quality management which has seen it become a supplier of choice to major automobile manufacturers in the world.

4. Gibbs Die Casting

Gibbs Die Casting, the other leader in the U.S. market is based in Henderson, Kentucky. The company specializes in the aluminum and magnesium die castings in the automotive industry, especially the transmission housings and power train parts. Gibbs lays strong emphasis on innovation where automation and sophisticated manufacturing techniques are being used to ensure high standards of efficiency and quality of work. The company also incorporates the concept of sustainability in its business by curbing wastage and encouraging environmental friendliness business practices.

5. Apex Aluminum Die Casting Co., inc.

Apex Aluminum Die Casting is situated in Ohio and it is used in automotive, electronic, and appliances industries. The business is reputable in working with mid-volume production lots, which makes it the perfect option with firms that require a steady output quality but does not require the enormous powers of bigger importers. The team of Apex is concerned with customer satisfaction, reliability of service, engineering and accuracy in manufacturing. They have established themselves as a reliable partner to a number of U.S. companies because of their good reputation to deliver consistent results.

6. KenWalt Die Casting Company

KenWalt Die Casting is based in California and has over several decades of experience with producing die castings; aluminum and zinc. The firm also focuses on bespoke jobs and serves the industries of both industrial equipment and consumer goods. KenWalt stands out as a company that collaborates closely with the client during the process of production and design, making sure that the products are exactly what the client needs. Their performance of both small and medium size production makes them a versatile option to companies with niche requirements.

7. Fort Recovery Industries, Inc.

Fort Recovery Industries is an aluminum and zinc die castings manufacturer whose headquarters is in Ohio and is also ISO certified. Their parts are common in the automobile, plumbing and appliance sectors. The strict quality expectations and quality performance possessed by the company has established it as a long-term supplier in the U.S market. Fort Recovery boasts of integrating traditional manufacturing skills with modern equipment to provide products which respond to the needs of the current industries.

Other Notable Players

Besides these top-notch firms, there are other renowned manufacturers that support the U.S. die casting industry, such as Shiloh industries, Alcast company and Mercury Castings. Such type of firms supply a great number of industries including heavy equipment and aerospace, electronics and renewable energy which is another clear indication of the versatility and power of aluminum die casting in America.

Top Aluminum Die Casting Firms in China

1. GC Precision Mould Co., Ltd. (aludiecasting.com)

Founded in 1999, GC Precision Mould Co., Ltd. (previously named Aluminum Die Casting China Limited) is a major company that deals with custom aluminum, zinc and magnesiumin painevalu. The company has more than 20 years experience and boasts of a wide scope of services, such as die casting, CNC machining, plastic molding, and surface finishing.

Capabilities:

- Muottiinvalu: Has been using high-pressure die casting (HPDC), gravity die casting, and sand casting to make parts of different alloys like ADC12, A380, A360, 6061 and 6063.

- CNC-työstö: It offers precision machining services on metal and plastic parts.

- Pintakäsittely: Provides anodizing, powder coating, electroplating, and painting services in order to increase the durability of parts and their appearance.

- Plastic Injection Molding: It focuses on precise molding services and high-precision plastic molds.

Toimialat, joita palvellaan:

Carmobile, electronic, telecommunications, medical equipment and consumer products.

- Verkkosivusto: https://aludiecasting.com

2. Die Casting Manufacturer (thediecasting.com)

The Die Casting Manufacturer is a Chinese based company that deals with high-precision die casting of aluminum, zinc, and magnesium. They are fully equipped with services such as die casting, CNC machining services, anodizing, powder coating, assembly services, and clients all over the world.

Capabilities:

- Muottiinvalu: This is a process which involves the use of high-pressure die casting to make parts with close tolerance and complicated shapes.

- CNC-työstö: It provides precision machining services according to the needs of clients.

- Pintakäsittely: Anodizing and powder coating are services that are offered to enhance the surface characteristics of cast components.

- Assembly: Provides assembly services to offer ready-to-use components to clients.

Toimialat, joita palvellaan:

Carmaker, electronics, telecommunications and consumer goods.

- Verkkosivusto: https://www.thediecasting.com

3. Sincere Tech Co., Ltd. (plasticmold.net)

Sincere tech Co. Ltd. is a professional painevalumuotti manufacturer in China and has a history of more than 13 years. They provide a complete family, die casting, mold design, CNC machining, surface finishing, and product assembly, aluminum, zinc (Zamak) and magnesium alloys.

Capabilities:

- Muottiinvalu: It is a company that deals with die casting in aluminum, zinc, and magnesium, and offers high quality parts whose dimensions are accurate.

- Mold Design: Provides design services of molds to satisfy the needs of a client.

- CNC-työstö: It offers high precision machining of metal and plastic parts.

- Pintakäsittely: Provides a range of finishing services, such as anodizing, powder coating and painting.

- Product Assembly: Back Office: This offers assembly services to complete products for the clients.

Toimialat, joita palvellaan:

Carmobile, electronic, domestic, medical, consumer goods.

- Verkkosivusto: https://www.plasticmold.net

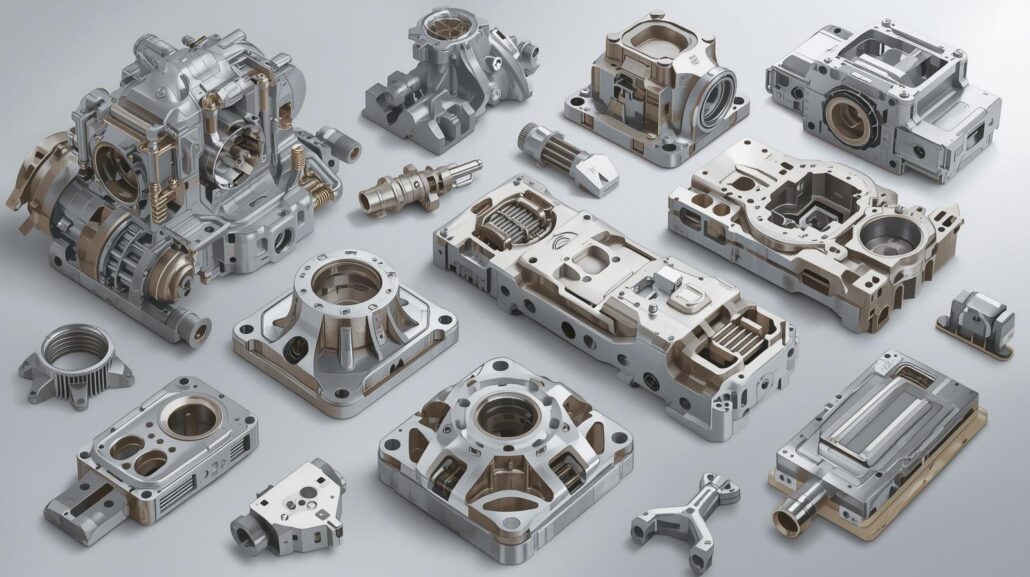

Metals in Die Casting of Aluminum

Though this process mainly involves the use of aluminum, the manufacturers make use of a particular alloy of aluminum, which is strong, durable, and castable. These alloys are selected depending on the purpose of use since each is different in terms of mechanical and chemical properties.

Widely used Aluminum Alloys in Die Casting:

A380 Alloy

- Good combination of strength, resistance to corrosion and light-weight.

- Typically used in automobiles, aerospace and consumer products.

A360 Alloy

- Reputed to be better in corrosion protection and resistance to pressure.

- Fit in aerospace and marine implementation where the survival in severe conditions is important.

ADC12 Alloy

- Electronics and consumer goods are popular.

- Good machinability and dimensional stability.

383 Alloy (ADC12 Equivalent)

- Has better hot cracking resistance than A380.

- Applied to components with fine details and complicated geometries.

A413 Alloy

- Offers great pressure tightness and machinability.

- Hydraulic cylinders, pumps and complex components are common.

Why Aluminium Alloys?

- Lightweight, but strong- Idealforn loweringthe weight in cars and machinery.

- Superior thermal performance – Suitable in the case of electronic housings and heat sinks.

- High resistance to corrosion – Trusts product life even under hostile environments.

- Recyclability – Aluminium alloys are capable of being recycled without any degradation.

Aluminum Die Casting Industry Trends in the United States

The United States is a rapidly evolving industry in the aluminum die casting, which is trying to meet the requirements of contemporary production. The future of this industry is determined by several significant trends:

Automotive and Aerospace lightweighting

With the increase in the use of electric vehicles (EVs) and fuel-saving designs, manufacturers have resorted to the use of light-weight aluminum die cast parts to decrease the overall weight of the vehicle without compromising the strength. Die casting is also being used to manufacture engine blocks, transmission housings and structural parts.

Electrification & EV Growth

The emergence of electric cars is creating a need to have die-cast components like motor cases, battery boxes, and frameworks that need to be strong and have a thermal conductivity. The U.S. firms are developing to take up these new demands.

Robotisation & Intelligent Production

To enhance precision, decrease cycle times, and eliminate defects, robotics, AI, and simulation software are adopted. The trend towards the creation of smart factories increases efficiency and assists manufacturers in remaining competitive.

Sustainability & Recycling

As the emphasis on green manufacturing has increased, firms are turning to the use of energy-saving furnaces, scrap aluminium recycling, and lessening wastefulness. This is becoming a central trend in the industry since the recycling of aluminum can be done indefinitely with no loss on quality.

Complex High-Precision Parts Demand

Die casting technology is evolving to create parts with smaller tolerances and complex designs as other sector,s such as electronics and medical equipmen,t demand more complicated components.

Päätelmä

Die casting of aluminum has evolved to be a key process in manufacturing robust, light and economical parts in a large spectrum of industries. Since the automotive and the aerospace industry up to the electronics industry and consumer goods, the U.S.-based companies have not only dominated the global market in precision die casting, but they have also been the industry leaders. They can be very reliable partners of businesses that are interested in long-term value, as they may fulfil the combination of innovation, quality control, and customer-oriented services.

The American aluminum die casting companies endeavour to adopt technology, which is one of their greatest strengths. They embrace automation, improved alloys, computer-aided design devices to maintain the high product performance as well as satisfy the increasing demand of challenging and high precision components. Also, they are committed to sustainability, in the form of energy-saving activities and massive recycling, which is in line with the current global move to adopt eco-friendly manufacturing processes.

Selecting an American die casting partner is also a practical benefit as it results in reducing lead times, enhancing communication, and having a more secure supply chain than sourcing abroad. To the business that may demand that international quality standards are strictly adhered to, the U.S manufacturers always make sure that the components are of high quality and they perform better than expected.

With the ongoing development of industries, which is being brought about by electrification, lightweighting and innovation, the importance of aluminum die casting will continue to increase. The American corporations featured in this article are in a good position to endorse these developments as they have the skills, accuracy, and trustworthiness. To companies that have trust in suppliers, a U.S. aluminum die casting company would not only provide high-quality products but also a solid basis on which future growth and success can be achieved.

Usein kysytyt kysymykset

What is aluminum die casting?

Aluminum die casting is a production process, in which molten aluminum is pressed into high points steel moulds, known as die. After the metal cools down and solidifies, it creates accurate, durable and lightweight parts. This technique is common in the automotive, aerospace, electronic and consumer products sectors.

Why American aluminum die casting firms?

The manufacturers in the U.S. provide quality, certified products, lead time is quicker, high automation and control over supply chains. Most of them also offer end to end solutions like machining, surface finishing and assembly assuring critical application precision and reliability.

What materials are normally used in aluminum die casting?

A380, A360, ADC12 and A413 are the most widespread aluminum alloys. These alloys have been chosen on account of their strength, corrosion resistance, thermal conductivity and machinability. Other companies process zinc and magnesium to use in special purposes.

What is the competition among the Chinese die casting companies?

Competitive prices and a variety of other services, including high-precision die casting, CNC machining, mold design, and surface finishing are provided by Chinese manufacturers, including GC Precision Mould (aludiecasting.com), The Die Casting Manufacturer (thediecasting.com) and Sincere Tech (plasticmold.net). They are serving the markets and industries of the world, such as automotive, electronics, and consumer goods.

Which sectors are the most helpful to die casting aluminum?

Die castings of aluminum are required in automotive, aerospace, electronic, medical equipment, house appliances, and machinery. Its lightweight, strong and accurate components are useful in enhancing the performance of the products, lower down its weight as well as the reliability of the products in the long run.