L'industrie moderne utilise le moulage sous pression de l'aluminium pour fabriquer des pièces solides, légères et de formes complexes. Si les secteurs de l'automobile, de l'aérospatiale, des télécommunications et de l'électronique grand public l'utilisent tous, c'est parce qu'il permet à la fois la production de masse et la création de pièces très précises. La demande de pièces moulées sous pression en aluminium de qualité ne cessant d'augmenter, il est important de s'adresser à un fournisseur connu et certifié.

Dans ce domaine, la certification IATF 16949 est très importante car il s'agit d'une norme de gestion de la qualité respectée et utilisée dans le monde entier dans l'industrie automobile. Cette certification garantit que le contrôle de la qualité, la gestion appropriée des risques et l'amélioration continue sont utilisés à chaque étape de la fabrication. Une entreprise certifiée ISO 16949 pour le moulage sous pression de l'aluminium démontre son engagement en faveur d'une qualité constante des produits et de la satisfaction des clients.

Être un fabricant de pièces moulées sous pression de haute précision et ITAF 16949 signifie répondre à des normes internationales rigoureuses et disposer des processus nécessaires pour minimiser les défauts, améliorer l'efficacité de la production et assurer la traçabilité complète des composants. Ils peuvent satisfaire les fournisseurs de niveau 1 et les équipementiers en livrant des composants qui respectent exactement les spécifications de l'entreprise.

En outre, le respect des moulage sous pression de l'aluminium et 16949 signifie qu'un fabricant peut répondre aux attentes dans le monde entier, principalement dans les domaines où il est important de mettre l'accent sur la sécurité et la sûreté des performances. Travailler avec un boîtier en aluminium moulé Un partenaire certifié IATF 16949 est bénéfique pour vos produits, permet de réduire les coûts à l'avenir et renforce les liens de votre chaîne d'approvisionnement.

Cet article examine comment un fabricant de pièces moulées sous pression en aluminium suit la norme IATF 16949 et son rôle.

Table des matières

ToggleMoulage sous pression de l'aluminium

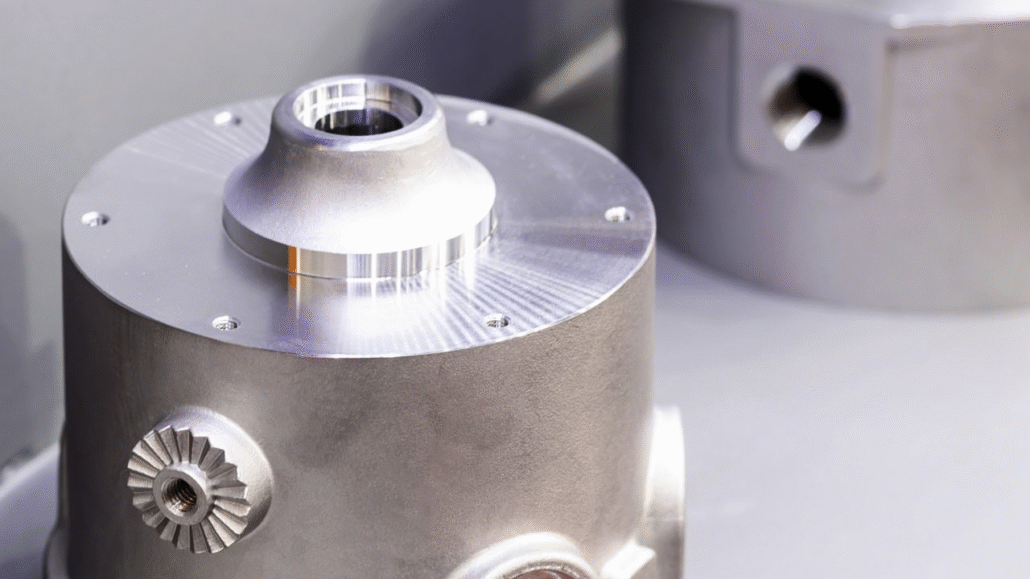

Le moulage sous pression de l'aluminium permet de fabriquer des pièces métalliques dont la forme est précise et dont la surface est parfaitement non poreuse. L'injection à haute pression d'aluminium en fusion dans un moule en acier permet de fabriquer rapidement des pièces complexes et de réduire les étapes de traitement ultérieures.

En raison de sa solidité et de sa légèreté, l'aluminium est largement utilisé dans de nombreuses industries. Les produits issus de ce processus sont couramment utilisés dans les moteurs, les boîtiers et les supports des voitures. Pour toute opération de moulage sous pression de l'aluminium et de certification ITAF 16949, le maintien de l'intégrité de ce processus est vital pour la qualité et la conformité.

Comment l'IATF 16949 aide-t-il le moulage sous pression ?

L'IATF 16949 est une norme internationale conçue pour les voitures, qui utilise la gestion de la qualité pour garantir la fiabilité des produits et de leurs processus. Le développement continu, la prévention des problèmes de qualité et la réduction des déchets dans la chaîne d'approvisionnement sont les principaux éléments du système, qui a été créé par l'International Automotive Task Force.

Pour les fabricants engagés dans le moulage sous pression de l'aluminium et la certification ISO 16949, la certification n'est pas seulement une exigence réglementaire, c'est un gage de confiance. Elle garantit que le fabricant suit des règles de qualité qui sont respectées partout. En outre, comme l'IATF 16949 correspond à l'ISO 9001, elle assure une gestion complète et adéquate de la qualité.

Pourquoi l'aluminium est-il utilisé dans le moulage sous pression ?

Le moulage sous pression bénéficie grandement de l'aluminium en raison de sa capacité à résister à la corrosion, de sa forte conductivité thermique et de sa légèreté par rapport à d'autres métaux comme l'acier et le laiton. En raison de ces qualités, ce matériau convient aux voitures, car la légèreté et les performances dépendent de l'efficacité énergétique.

Une certification IATF 16949 montre que tous ces avantages sont obtenus par l'entreprise. Par exemple, les fabricants qui se concentrent sur le "moulage sous pression de haute précision" et les normes ISO 16949 peuvent garantir à leurs clients une performance constante des produits et une variance minimale de la production.

Qu'est-ce qui fait la fiabilité d'un fabricant de pièces moulées sous pression en aluminium ?

Le choix d'un fabricant compétent est très important pour les entreprises qui pratiquent le moulage sous pression de l'aluminium. Un fabricant doit non seulement posséder le savoir-faire nécessaire, mais aussi respecter toutes les normes de qualité. Voici quelques-unes des caractéristiques essentielles que vous devriez remarquer :

- Le respect de la norme IATF 16949 permet de s'assurer que le fabricant peut fournir des produits de qualité conformes aux normes automobiles internationales.

- Les technologies de pointe permettent à un bon fabricant d'améliorer la conception des matrices et le déroulement de la coulée.

- Il est nécessaire d'être flexible dans la production et de modifier les conceptions en fonction de la demande de chaque client.

- Contrôle de la qualité : La surveillance en temps réel, l'analyse des données et les essais non destructifs sont quelques-uns des outils utilisés pour garantir la qualité du moulage sous pression de l'aluminium et des processus ITAF 16949.

Utilisation de la précision dans le moulage sous pression

Un bon moulage sous pression dépend principalement d'une ingénierie précise. Elle confirme que les composants respectent les directives strictes en matière de dimensions et de performances. Les fabricants qui s'identifient comme des fabricants de pièces moulées sous pression de haute précision et ITA 16949 se donnent beaucoup de mal pour mettre en œuvre des normes rigoureuses tout au long du cycle de conception et de production.

Grâce aux logiciels CAD/CAM, à l'inspection de la qualité et aux processus automatisés, la production est aussi proche que possible des exigences spécifiques. Pour des applications telles que les boîtiers de transmission, les boîtiers électroniques et les composants automobiles importants, la précision requise est très importante.

Pourquoi la gestion de la qualité est-elle importante ?

Un système de gestion de la qualité (SGQ) bien structuré permet de produire des biens de même qualité en permanence. Dans l'industrie du moulage sous pression de l'aluminium, le respect des principes de l'IATF 16949 permet de contrôler les processus, de réduire les risques et de s'améliorer constamment.

En suivant l'IATF 16949, un fabricant de pièces moulées sous pression de haute précision et l'itaf 16949 garantissent non seulement la qualité, mais aussi la traçabilité et la responsabilité. Tout est vérifié et confirmé tout au long de la chaîne d'approvisionnement afin de réduire les risques de problèmes et de défauts.

Vous trouverez ci-dessous un tableau détaillé et professionnel qui décrit les principaux aspects de la Fabricant de pièces moulées sous pression en aluminium et IATF 16949L'objectif est d'intégrer les informations pertinentes dans différentes catégories telles que le processus, les avantages, la certification et la pertinence pour l'industrie.

Ce tableau est idéal pour un site web, une brochure ou une présentation.

Moulage sous pression de l'aluminium et IATF 16949 - Vue d'ensemble

| Catégorie | Détails |

| Processus de fabrication | L'aluminium est fondu et injecté dans un moule en acier sous haute pression, ce qui permet de produire des formes complexes avec une excellente précision dimensionnelle. |

| Principaux matériaux utilisés | Les alliages d'aluminium (par exemple A380, ADC12, AlSi10Mg) sont connus pour leur résistance, leur légèreté et leur conductivité thermique. |

| Industries d'application | Automobile, aérospatiale, électronique, équipement industriel, télécommunications, biens de consommation. |

| Avantages du moulage sous pression de l'aluminium | - Composants légers - Rapport résistance/poids élevé - Excellente finition de surface - Rendement élevé - Résistance à la corrosion |

| Importance de la précision | Des tolérances serrées et des détails fins peuvent être obtenus, ce qui est idéal pour les pièces de moteur, les boîtiers, les connecteurs, les supports et les composants structurels. |

| Qu'est-ce que l'IATF 16949 ? | Norme mondiale de gestion de la qualité pour l'industrie automobile, basée sur la norme ISO 9001 avec des exigences supplémentaires spécifiques à la construction automobile. |

| Avantages de la certification IATF 16949 | - Qualité constante des produits - Réflexion fondée sur les risques - Prévention des défauts - Meilleure satisfaction des clients - Avantage concurrentiel |

| L'importance de la certification | Assurer la traçabilité, les procédures normalisées, la conformité réglementaire et l'amélioration continue des performances. |

| Clients cibles | OEM, équipementiers automobiles de niveau 1 et 2, concepteurs de systèmes industriels et développeurs de produits sur mesure. |

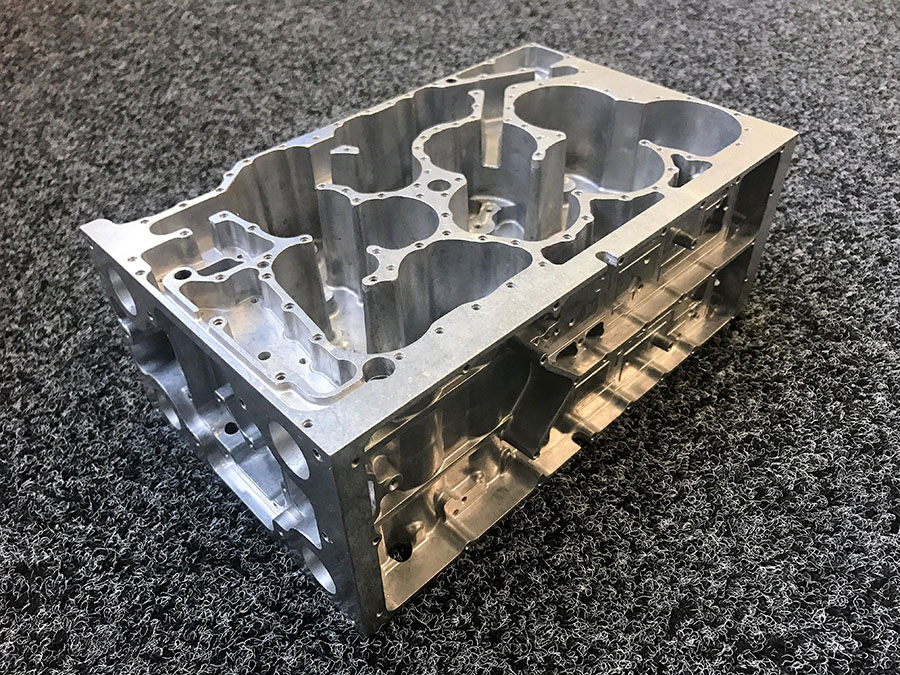

| Exemples de composants typiques | Boîtes de vitesses, blocs moteurs, carters de pompes, carters de moteurs, supports, dissipateurs thermiques et boîtiers électroniques. |

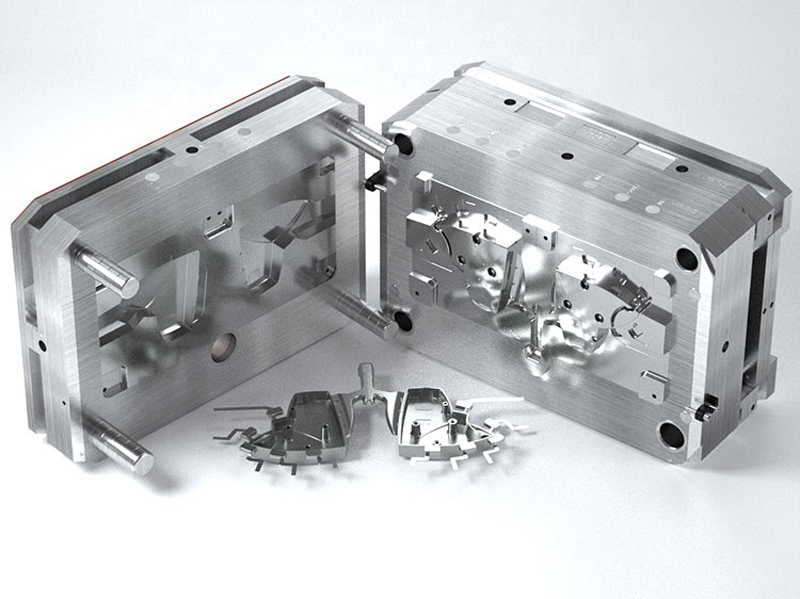

| Expertise en matière d'outillage de moulage sous pression | Comprend la conception de moules, l'usinage CNC, le traitement thermique et les logiciels de simulation pour le moulage de précision. |

| Options de finition de surface | Usinage, anodisation, revêtement par poudre, peinture, polissage et sablage. |

| Méthodes d'inspection de la qualité | CMM (machine à mesurer les coordonnées), inspection aux rayons X, essais de pression, contrôles visuels, essais de dureté. |

| Facteurs de durabilité | L'aluminium est 100% recyclable ; les fabricants utilisent souvent des équipements économes en énergie et des méthodes de production respectueuses de l'environnement. |

| Conformité aux normes mondiales | ISO 9001, IATF 16949, RoHS et REACH (en fonction des exigences des clients et des normes régionales). |

| Pourquoi choisir un partenaire certifié ? | Un partenaire certifié garantit l'assurance de la qualité, une exécution efficace du projet, moins de retours ou de défauts et de meilleures relations à long terme. |

Applications dans de nombreux autres domaines

Le moulage sous pression est très important dans la fabrication des voitures car il fournit des blocs moteurs, des éléments pour les transmissions et des cadres pour les carrosseries. Cependant, les avantages des statistiques peuvent être appliqués de différentes manières. L'aérospatiale, l'électronique et les machines industrielles utilisent toutes les matériaux résistants et légers fabriqués à partir de la fibre de carbone.

Lorsque les pièces doivent répondre à des fonctions de sécurité critiques, telles que celles des systèmes de freinage ou des supports structurels, le besoin d'un fabricant de pièces moulées sous pression de haute précision et de l'ITA 16949 devient encore plus prononcé. En raison de leurs compétences et de leurs procédures éprouvées, les OEM et les fournisseurs de niveau 1 considèrent ces entreprises comme d'excellents partenaires.

Difficultés liées à la production de pièces moulées sous pression en aluminium

Cependant, l'utilisation du moulage sous pression de l'aluminium est associée à certains problèmes. Lorsque la fabrication n'est pas effectuée sous un contrôle strict, des problèmes tels que des pièces poreuses, des pièces qui ne sont pas de la même taille et des défauts à la surface peuvent survenir. En outre, l'usure des moules et la fatigue thermique peuvent réduire la durée de vie des moules et la qualité des pièces.

C'est pourquoi les fabricants doivent suivre strictement leur processus et investir des efforts dans la mise à niveau et l'entretien de leurs matrices. Les fabricants certifiés engagés dans le moulage sous pression de l'aluminium et l'ITAF 16949 déploient souvent des analyses prédictives et une surveillance automatisée pour prévenir les problèmes de qualité avant qu'ils ne surviennent.

Prendre soin de l'environnement

Le développement durable est aujourd'hui une préoccupation majeure de l'industrie manufacturière. L'aluminium peut être recyclé à l'infini tout en conservant ses qualités, ce qui le rend écologique. Correctement optimisé, le moulage sous pression utilise moins de ressources et moins d'énergie.

Un fabricant responsable de pièces moulées sous pression en aluminium et de la norme 16949 suit la meilleure méthode de production et se préoccupe également de l'approvisionnement et du recyclage. Souvent, les entreprises qui suivent la norme IATF 16949 incluent des objectifs environnementaux dans leurs projets d'amélioration continue.

Tendances en matière de moulage sous pression et importance d'une bonne qualité

L'amélioration des technologies de fabrication entraîne une augmentation des exigences imposées aux fabricants de pièces moulées sous pression. Voici quelques-unes des nouvelles tendances :

- Utilisation de l'IA et de l'apprentissage automatique pour améliorer les paramètres utilisés dans le casting.

- Les jumeaux numériques permettent de tester et d'affiner la conception des matrices.

- Les composants légers des véhicules électriques étant de plus en plus populaires, les fabricants utilisent davantage d'aluminium.

En raison de cette évolution, on attend des organisations qu'elles adoptent des pratiques certifiées. Le fait de posséder le label "Aluminium die casting and 16949" signifie qu'une entreprise est très performante sur un marché en constante évolution.

Le processus de recherche d'un partenaire

Il est très important de vérifier soigneusement les antécédents et les compétences d'un partenaire de moulage sous pression avant de prendre une décision. Outre la confirmation de la certification IATF 16949, les entreprises doivent prêter attention à certains aspects spécifiques des performances du fabricant.

- les résultats obtenus par l'entreprise dans le passé et les commentaires de ses clients

- Compétences en matière d'équipement et de développement

- En utilisant une procédure d'assurance qualité

- L'entreprise peut-elle respecter les délais de livraison des produits ?

Les entreprises fiables de moulage sous pression d'aluminium et de 16949 offrent à leurs clients des produits de qualité et du confort. Tous les articles qu'elles vous fournissent sont exempts d'erreurs car elles respectent les normes internationales.

CNM TECH obtient la certification IATF 16949 pour son moulage sous pression d'aluminium de qualité supérieure

Les entreprises du secteur manufacturier ont besoin de processus fiables et d'une qualité sûre, car le marché est très concurrentiel. CNM TECH, une entreprise de moulage sous pression d'aluminium de premier plan, a obtenu la certification IATF 16949, reconnue dans le monde entier. L'obtention de cette marque prouve que CNM TECH continue à se concentrer sur l'excellence, la créativité et la satisfaction de ses clients dans le domaine du moulage sous pression.

Grâce aux innovations de pointe de CNM TECH, à ses travailleurs bien formés et à ses solides systèmes de qualité, les clients des secteurs automobile, industriel et électronique font grandement confiance à l'entreprise. La certification du moulage sous pression de l'aluminium et de l'ITAF 16949 confirme que CNM TECH applique des pratiques strictes de gestion de la qualité, spécifiquement adaptées aux exigences de l'industrie automobile.

Comment nos clients bénéficient-ils de notre certification IATF 16949 ?

L'IATF 16949 est considérée comme la meilleure norme de qualité dans la chaîne d'approvisionnement automobile. Elle est basée sur la norme ISO 9001 et exige davantage d'activités qui contribuent à l'amélioration continue, à la prévention des défauts et à l'élimination des déchets et des variations.

En obtenant cette certification, CNM TECH montre qu'elle est capable de produire des biens de qualité supérieure et constante pour les OEM et les fournisseurs de niveau 1. En tant que fabricant de pièces moulées sous pression de haute précision et ITA 16949, nous nous engageons à fournir des composants en aluminium conçus avec précision qui dépassent les attentes des clients, tant au niveau de la fonction que de la forme.

Des fonctions supérieures, des normes fiables

Grâce à des installations modernes et à une équipe d'ingénieurs compétents, CNM TECH est en mesure de fabriquer des pièces en aluminium répondant à des exigences très spécifiques. Ce procédé permet un meilleur écoulement de la matière, réduit les signes de porosité et offre de bonnes surfaces, ce dont ont besoin les produits automobiles et industriels de haute qualité.

Opérant désormais sous le régime de la coulée sous pression de l'aluminium et des directives ITAF 16949, CNM TECH intègre des contrôles de qualité rigoureux à chaque étape de la production. Toutes les étapes, de l'inspection des matières premières aux derniers contrôles, sont correctement suivies, gérées et constamment améliorées afin de garantir une production parfaite.

Nos clients du monde entier nous font confiance

Le certificat IATF 16949 permet à CNM TECH de proposer ses produits aux meilleures entreprises du secteur. Notre certification indique à nos clients que nous travaillons toujours dans le respect des normes les plus strictes en matière de qualité, de sécurité et de développement durable.

Notre rôle est de concevoir, construire et produire des pièces et des composants de qualité en conformité avec les normes de moulage sous pression de l'aluminium et les normes 16949.

Le meilleur partenaire stratégique de fabrication

La qualité est la clé de tout ce que nous faisons chez CNM TECH. Grâce à l'application réussie de la norme IATF 16949, nous nous sommes hissés au sommet du secteur du moulage sous pression de l'aluminium dans le monde entier.

Conclusion

Dans l'ensemble, il s'agit d'une certification entreprise de moulage sous pression d'aluminium joue un rôle crucial sur le marché actuel, axé sur la qualité et la concurrence acharnée. Étant donné la demande croissante de pièces métalliques légères et résistantes, les entreprises doivent s'appuyer sur des partenaires compétents dans ce domaine et qui respectent les normes mondiales IATF 16949.

L'obtention de la certification ISO 16949 pour le moulage sous pression de l'aluminium témoigne de l'engagement d'un fabricant en faveur de la qualité, de la précision et de la satisfaction du client. Elle garantit aux clients que leurs produits sont traités avec le plus grand soin, que les domaines d'amélioration sont repérés et que leur approvisionnement est traçable. Pour les entreprises qui recherchent la fiabilité et des partenariats à long terme, travailler avec un fabricant de pièces moulées sous pression de haute précision et l'ITA 16949 est un gage de confiance et de tranquillité d'esprit.

En plus de fabriquer d'excellents produits, les fabricants impliqués dans le moulage sous pression de l'aluminium et les pratiques 16949 se consacrent également à rendre l'ensemble de l'industrie manufacturière plus efficace et plus respectueuse de l'environnement. Grâce à l'attention qu'elles portent à la qualité et à l'innovation, les industries peuvent faire face aux développements technologiques et à la protection de l'environnement.

Tout partenaire agréé IATF 16949 garantit que vos pièces automobiles, industrielles ou électroniques sont fabriquées dans un souci de durabilité et d'excellentes performances.

FAQ

1. Quels sont les avantages du moulage sous pression et pourquoi utilise-t-on l'aluminium ?

Dans le cas du moulage sous pression, l'aluminium en fusion est injecté à grande vitesse dans un moule dur sous une pression importante. Comme l'aluminium est léger, qu'il ne se corrode pas et qu'il a des propriétés solides, il est généralement préféré.

2. Quels sont les avantages pour les clients d'une entreprise certifiée IATF 16949 ?

La norme IATF 16949 est reconnue dans le monde entier dans l'industrie automobile. Elle garantit que toutes les pièces produites sont de qualité, qu'elles sont traçables et que l'on peut obtenir des pièces mieux fabriquées avec des changements mineurs ou nuls aussi souvent que possible.

3. Quels sont les domaines couverts par les produits de CNM TECH ?

Nous fournissons des pièces en aluminium moulé sous pression aux secteurs de l'automobile, de l'électronique, de l'industrie et des biens de consommation, car nous traitons diverses spécifications difficiles.

4. Comment CNM TECH garantit-il une grande précision et une excellente qualité ?

En tant que fabricant de pièces moulées sous pression de haute précision et ITA 16949, nous utilisons des équipements de pointe, des inspections rigoureuses et des systèmes automatisés pour garantir que chaque pièce est impeccable et conforme aux normes internationales.

5. Comment lancer un projet chez CNM TECH ?

Prenez contact avec nous en utilisant le site web www.thediecasting.com. Notre équipe d'ingénieurs est prête à découvrir ce dont vous avez besoin, à vous fournir une assistance technique et à concevoir une solution personnalisée pour vous.