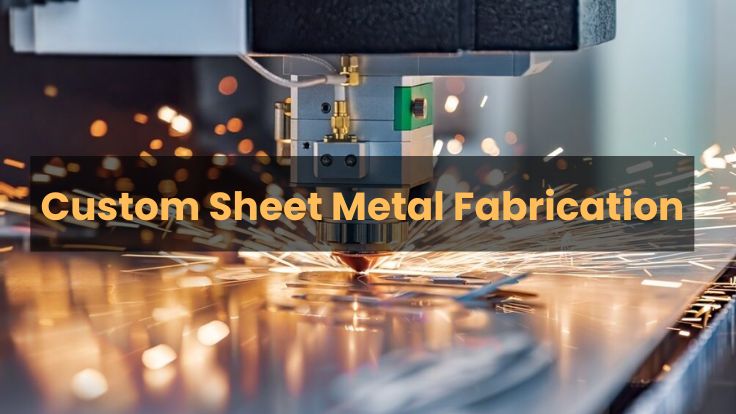

Fabrication de tôles sur mesure dans les industries modernes

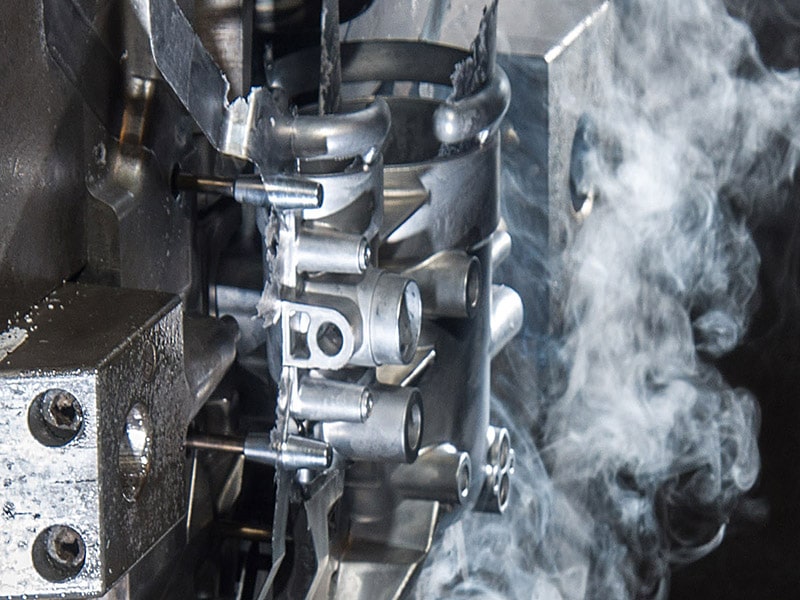

moulage sous pression de l'aluminiumCustom sheet metal fabrication is now an activity that has established manufacturing industries in a variety of categories in the modern face of manufacturing. Whether in the form of cars and electronics, construction and healthcare, fabricated metal components play an essential role in the design, operation and durability of the enormous variety of products. It entails the sheet metal being cut, bent, shaped and assembled, based on specifications to fit the match, and manufacturers can make highly customised, durable and efficient parts. Among the most important industries that depend on this capacity is the automotive industry, in cases where the so-called custom automotive sheet metal fabrication will guarantee the production of high-performance body panels, supporting structure, and engine components. Such components should also have high standards in terms of weight, strength, and safety; hence, precision and customisation are essential. More and more foreign companies are resorting to the services provided by more advanced manufacturers like the car sheet metal fabrication in China because of favourable cost rates. Chinese manufacturers provide comprehensive services using advanced CNC equipment and short production schedules, which makes they useful partners in the global supply chain. Along with cars, the fabrication of sheet metal is a vital aspect in such areas as the aerospace industry, electronics, medical equipment, and the food processing industry. Such industries require great tolerances, corrosion resistance, and customised surface finishes, all of which can be provided by sheet metal fabrication. In this article, we are going to look at the complete range of this discipline, beginning with classic methods to the state of the art automation, mainly concentrating on automotive uses and the contribution of leading world actors, such as China. What is Custom Sheet metal fabrication? The term custom sheet metal fabrication is used when it comes to designing and manufacturing metal members or structures that can meet the specific needs of a particular project. In contrast to the mass-produced components, custom fabrications take unique solutions to specific sizes, materials and applications. This fabrication incorporates laser cutting, water jet cutting, punching, welding, forming and finishing of the surface. The most common ones are stainless steel, aluminum, galvanized steel, copper, and brass, among others, all selected due to their strength, conductivity, corrosion, and weight requirements. Manufacturers and engineers work hand in hand to make sure that all specifications are followed to the micrometre. Main Items in the Process 1. Design and Prototyping: A digital blueprint is sketched with the aid of CAD (Computer-Aided Design) software. Prototypes are frequently manufactured in order to run tests on how they work before large-scale production can commence. 2. Cutting and Shaping: The metal sheet is precisely shaped by using high-precision cutting tools to give very little tolerance. 3. Bending and Forming: The Sheet is curved to form complex shapes by bending and forming equipment, which includes press brakes. 4. Welding and Assembly: There are various parts which are assembled through TIG welding, MIG welding or spot welding. 5. Finishing: Finishing processes such as powder coating, polishing or anodising increase strength and aesthetics. Custom Automotive Sheet Metal Fabrication Rise The Rise of custom automotive sheet metal fabrication began in the late nineteenth century, which saw the birth of the automobile industry. This period saw many people lose their lives and even more become injured by automobile accidents. This again led to the production and use of automobile insurance as a solution to automobile accidents. Precision and customization are vital in the car manufacturing business. The custom automotive sheet metal fabrication is a significant element in the production of car body panels, chassis parts, heat shields, as well as engine enclosures. Such parts should be of high safety rating, aerodynamic, and aesthetically pleasing. Customisation gains significant relevance in the performance car, restoration car, electric car, and luxury vehicle production. The engineers may also need some special structural bracing or a project in terms of aerodynamic panels, which cannot be produced by general mass production. The benefits of the exercise of best sheet metal car fabrication are that: Common Materials in Sheet Metal Fabrication One most crucial decisions of the custom sheet metal fabrication is the choice of material. Whether it is carbon steel or stainless steel, it traverses all the aspects, including strength and corrosion resistance and even weight and workability. Knowing the nature of widely used metals enables an engineer to make a wise decision to maximise the efficiency and economic gains. Aluminium: Extremely Light and Non-Corrosive Aluminum is the most common material that is used in fabrication custom sheet metal. It is perfect for aerospace, electronic, and transport application materials because of its inherent corrosion resistance, easy weight, and good formability. It is also a highly conductive material, such that it can be used in enclosures and parts that radiate heat. As per the custom automotive sheet metal fabrication, aluminium is frequently used in the body parts and as a heat deflector to lighten the weight of the vehicle, without compromising its strength. Stainless Steel: Strong and Clean Stainless Steel The strength of stainless and the fact that stainless is non-corrosive an attributes of the material. It is mainly utilized in food grade, medical and architectural applications where cleanliness and strength are important. Stainless steel may be specified in use of products that are under severe conditions of weather or that need a high-end finish in the custom sheet metal fabrication services. It is resistant to the effects of chemicals, water or high temperatures, hence its common use in many industries. Cold Rolled Steel: Versatile, Tough and Economical In the field of sheet metal custom fabrication, cold rolled steel (CRS) can be a common decision in construction when tight tolerances and a smooth surface are needed. It is cheap to weld or machine. Although it is likely to rust when not coated, it can be applied in buildings or painted. CSR is mostly applied in the cabinet, brackets, as well as enclosures in numerous industries such as the automotive industry, the construction industry and consumer