黒ニッケル電気メッキは一般的な仕上げ方法の一つで、金属片の外観と寿命を向上させます。黒く滑らかな外観を与え、表面の耐食性と硬度を高めます。このため、自動車産業、電子機器、宝飾品、装飾金物など、ほとんどの分野で人気があります。アルミニウムには天然の酸化皮膜があるため、アルミニウムにニッケルめっきを施すのは難しいため、アルミニウムにニッケルめっきを施すかどうかは、多くの初心者や専門家の間で議論の的となっています。ニッケル層は、適切な準備がないと効率的に付着できず、剥がれたり、不均一な仕上がりになったりします。.

黒ニッケル電気メッキは、自宅や小さな工房でも可能かどうかという質問もよくあります。小規模な手配は可能ですが、専門的な工程を経ることで、より信頼性が高く安定した結果が得られます。黒色電気メッキニッケルは、美的価値だけでなく保護価値もあるため、貴重な素材です。黒色仕上げは、工具、トリム、宝飾品、工業部品にモダンで洗練された外観を与えます。.

本マニュアルでは、ブラックの全プロセスについて説明する。 ニッケル電気めっき. .表面の準備、メッキ工程、後処理工程、典型的な落とし穴について知ることができます。最後には、ブラックニッケルが他の仕上げと比べて最も使用されている理由や、機能性と装飾性の両方を兼ね備えている方法を知ることができます。.

目次

トグル黒ニッケル電気メッキとはどういう意味ですか?

黒ニッケル電気めっきは、ニッケルの合金を金属表面に析出させる電気化学的プロセスである。従来のニッケルメッキとは対照的に、最終的な仕上がりは、暗色、マット、または半光沢仕上げとなります。そのため、装飾品として非常に人気があります。また、このプロセスは金属表面の強度を高め、傷や摩耗、腐食の影響を受けにくくします。.

アルミニウムめっきの場合はもっと複雑だ。当然ながら、アルミニウム上には金属酸化物が形成され、これが金属の付着を阻害する。これが、黒ニッケル層を塗布する前に、アルミニウムのニッケルめっきを特別に洗浄し、前処理しなければならない理由です。とはいえ、黒色電気めっきニッケルは、保護性に優れ、外観も黒っぽくなります。.

黒ニッケル電気めっきの利点

耐食性

腐食保護は、黒ニッケルの電気めっきが選ばれる主な理由の1つです。ニッケル層は、水分、塩分、化学物質などの環境要因から下地金属を保護します。これは、自動車部品、ハードウェア装置、工場設備に特に重要です。.

表面硬度の向上

ニッケル電着ブラックは表面の硬度を高めます。これにより、耐摩耗性が向上し、部品の傷が減少します。この耐久性の向上は、工具、機械部品、金物にとって非常に価値のあるものです。.

美的アピール

ブラックニッケルはダークで気品があり、その仕上げは目に訴えるものがある。装飾品、宝飾品、車の内装、電気ケーシングなどに幅広く使用されています。従来のニッケルメッキは明るい銀色の外観でしたが、黒ニッケルはモダンで上質な外観を作り出します。.

長寿と経済

黒ニッケルメッキは、腐食や磨耗を防ぐために部品をコーティングすることで、部品の寿命を延ばします。そのため、メンテナンス費用や交換費用を抑えることができ、産業界と趣味愛好家の両方にとって手頃なソリューションとなります。.

汎用性

黒ニッケルめっきは、アルミニウム、鉄、真鍮などの金属に施すことができます。この柔軟性により、様々な用途に適しています。.

ニッケルめっきアルミニウムの問題

しかし アルミニウムのニッケルめっき は可能だが、それには困難がある。アルミニウムの自然酸化被膜は、ニッケル層の付着の障害となる。メッキを成功させるには、洗浄、エッチング、前処理の活性化が重要です。適切な前処理が行われないと、剥離、不均一な被覆、仕上がりの欠陥が生じます。.

もう一つの難点は、最終的な色をコントロールする能力である。黒ニッケル電気メッキは、メッキのパラメータが最適化されていないと、色が濃くなったり、ムラになったりすることがあります。このような理由から、通常、工業用グレードの出力には、プロフェッショナルなセットアップが推奨されます。.

黒ニッケル電気めっきプロセス ステップバイステップ

表面処理

表面処理は適切に行わなければならない。アルミニウムやその他の金属を洗浄し、油脂、汚れ、酸化を除去する。アルミニウムの場合、亜鉛鋳造のステップを定期的に行う。これによって亜鉛の薄い層が形成され、ニッケルの密着性が高まる。洗浄・活性化後に洗浄する。.

電気めっきセットアップ

推奨される薬品と温度レベルを使用して、黒ニッケル浴を温める。必要な電流を流すには電源が必要です。その後、被加工物を陽極として接続し、陰極材(通常は鉛またはステンレス鋼)を接続して回路を完成させます。.

電気めっきプロセス

金属片を黒ニッケル溶液に加える。浴槽の仕様に従って電流を流す。ニッケルイオンが金属表面に析出し、濃色で均一な保護皮膜が形成される。温度、電流、めっき時間を注意深く観察する。.

すすぎと乾燥

プレート。きれいな水で部品をすすぎ、残っている薬液を洗い流します。ウォータースポットや仕上がりにムラが出ないように拭き取る。.

治療後

耐食性と硬度を向上させるため、処理後に熱硬化またはシーリングを行う場合がある。これは、めっき層が長持ちし、強靭であることを保証するために行われる。.

黒ニッケル電気めっきの用途

ジュエリー&アクセサリー

ジュエリーは、黒ニッケルの助けを借りて、滑らかでモダンな外観に仕上げられます。リング、ブレスレッ ト、時計ともに、耐食性に優れているだけでなく、美的にも 魅力的です。.

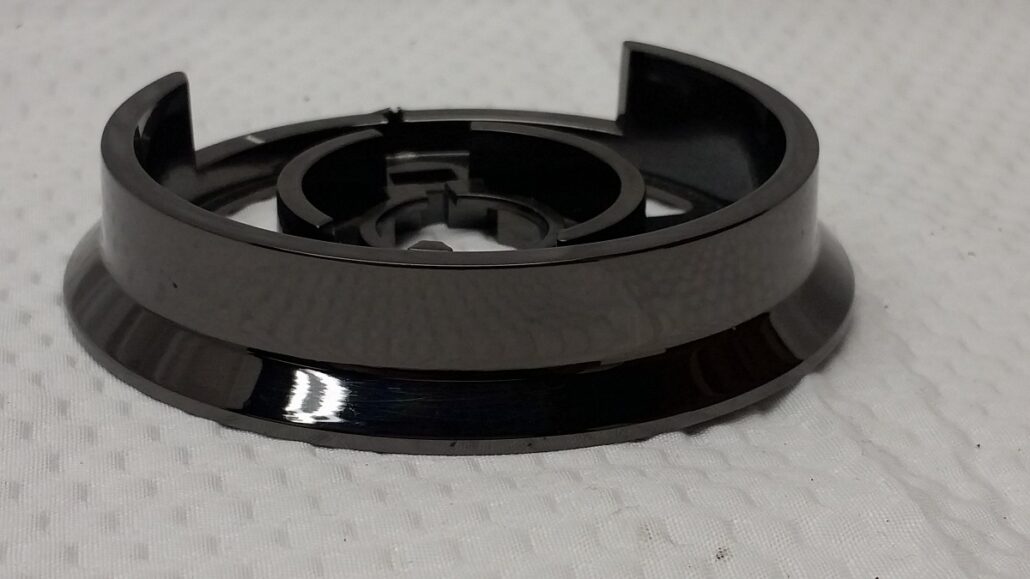

自動車産業

クルマのトリムやハンドル、装飾部品には通常、黒ニッケルメッキが施されています。これにより、耐久性と上質な外観を実現しています。.

エレクトロニクスとハードウェア

電子機器の筐体、スイッチ、コネクターに黒ニッケルを電気メッキすることも、摩耗を防ぎ、美観を良くすることを目的としています。.

産業用工具

黒色電気めっきニッケルは、機械の硬度と寿命を高めるため、機械の部品や工具に有用である。.

黒ニッケル電気めっきの間違い

熟練した技術者であっても、アルミニウムへのニッケルめっきやニッケルへの黒色めっきで問題が発生する可能性があります。いくつかの失敗例を挙げます:

- 表面のクリーニングが不十分: 汚れ、グリース、油分があると十分な接着が阻害され、剥離や不均一な層が生じることがある。.

- アルミニウムの前処理をなくす: アルミニウム上の酸化皮膜はめっきを阻害する。亜鉛めっきや活性化が正しく行われないと、弱いめっきが得られる。.

- 風呂または現在の温度: 過度に高温にすると表面が焼け、過度に低温にするとメッキが薄く弱くなる。.

- メッキ後のすすぎを怠った: 残留した化学薬品は、長期的には筋やくすみ、腐食の原因となる。.

- シーリングや後処理の省略: これは耐食性を低下させ、メッキ部品の寿命も低下させる。.

このような落とし穴に注意することで、黒ニッケル電気めっきの仕上がりの質を下げることが可能です。.

黒ニッケルめっきを成功させるために

- 金属面は常に清掃し、開いておくこと。.

- アルミニウムの場合、接着性を持たせるために亜鉛メッキを施す必要がある。.

- 同じ結果を得るために、めっき浴の温度と電流を調節する。.

- 適切なすすぎと乾燥方法を用いることで、筋を避けることができる。.

- 品質を保証するために、大型部品や重要部品の専門的な構成を考慮する。.

他の仕上げに対する利点

その点、黒ニッケルはクロームメッキや通常のニッケルメッキよりも優れている:

- ダークでエレガントな美学

- 摩耗防止と腐食防止。.

- アルミニウムや他の金属との適合性。.

- 寿命も長く、メンテナンスも簡単だ。.

ブラックニッケルは、クロームのような明るい印象は与えられないかもしれないが、保護性能に優れ、モダンな外観を持つため、ほとんどの業界で高く評価されている。.

素材黒ニッケル電気メッキ

ベースメタル

ブラックニッケルコーティングで覆われているのはベースメタルです。一般的な母材には、アルミニウム、鉄、真鍮、銅などがあります。アルミニウムは軽量で、自動車、電子機器、装飾産業など幅広い用途に使用されているため、アルミニウムめっきはニッケルめっきの中でも非常に好まれる方法です。また、一般的なメッキは鉄や真鍮に施され、腐食しにくく、摩耗に強くなります。母材の問題も、密着性と耐久性に非常に重要である。.

ニッケル・ソース

めっき浴の主成分はニッケルイオンである。ニッケルイオンは、電流を流すと母材に析出する。一般的に、ニッケル源は硫酸ニッケル、塩化ニッケル、またはその両方です。これらの添加剤は、電気めっきされた黒ニッケルに均質な被覆を与えます。.

黒ニッケル添加剤

黒ニッケルめっきプロセスでは、黒っぽい外観を得るために特定の添加剤が必要です。これらは有機化合物または無機化合物で、色、輝度、均一性を調整します。添加剤は、黒色電気めっきニッケルの硬度と耐食性に関与しています。均一で望ましい仕上がりにするためには、適切な濃度にすることが重要です。.

電解質溶液

電解液は、母材に析出するニッケルイオンの移動を可能にする媒体です。一般的に、水、ニッケル塩、酸、黒色ニッケル添加剤で構成されています。電解液の適切なpHと温度は、均一なめっきを行い、筋や色むらなどの欠陥を避けるための鍵となります。.

正極および負極材料

めっきプロセスでは、ベース金属が陽極となり、適合する陰極(通常はステンレス鋼または鉛)が回路を完成させるために使用される。これらの材料は、黒色電気めっきニッケルの析出プロセスを滑らかで均一にします。汚染を最小限に抑え、めっき全体の品質を高めるために、高品質の電極が選択されます。.

他のめっき仕上げとの比較-黒ニッケル

黒ニッケルと標準ニッケルめっきの比較

黒ニッケル電気めっきは、黒っぽいつや消しまたは半光沢仕上げに使用され、標準ニッケルめっきは、明るい銀色仕上げに使用されます。黒色電気ニッケルめっきは、魅力的で耐食性が高いだけでなく、宝飾品、自動車トリム、電子ケーシングなどの装飾用途に最適です。ニッケルめっきは標準的で、保護と光沢に重点を置いていますが、黒ニッケルのような現代的でスタイリッシュな外観ではありません。.

黒ニッケルとクロムめっきの比較

クロムメッキは反射率が高く、非常に硬いのですが、圧力がかかると脆く剥がれやすくなります。一方、黒ニッケルを電気メッキすると、層は柔軟で耐久性があります。そのため、特にアルミニウムや軽量の金属への効果が高まります。黒ニッケルは、腐食や磨耗に強く、クロームでは出せない効果的なダークな外観を与えます。.

頑丈さと耐摩耗性

黒ニッケルも標準ニッケルも、表面の硬度と耐久性を高めます。しかし、アルミニウムに黒ニッケルメッキを施すと、傷や酸化に対する層が増えます。また、黒色仕上げは、光沢のあるニッケルやクロムよりも細かい摩耗跡をよくカバーするため、頻繁に扱う工具、ハンドル、金具に便利です。.

金属を問わない汎用性

ニッケル電気メッキブラックは、アルミニウム、スチール、真鍮など、さまざまな金属に使用できます。そのため、鉄に最適なクロムや、数回の重ね塗りが必要な標準的なニッケルよりも適合性が高くなっています。黒ニッケルめっきは、耐久性、耐食性、美観を1回の処理で確保するために使用されます。.

美的アピール

最後に、ブラックニッケルのもう一つの利点は、現代的で洗練された外観です。一般的なニッケルメッキやクロームメッキは見た目を重視しますが、ブラックニッケルはかすかな高級感があります。そのため、作業用としても装飾用としても非常に人気があります。.

結論

黒ニッケル電気めっきは、金属部品の美しさと寿命を向上させる最も効率的な方法です。黒ニッケル電気メッキは、滑らかで黒っぽい外観を持ち、耐食性と表面硬化が非常に優れています。アルミニウムへのニッケルめっきは、多くの人が疑問に思うかもしれませんが、アルミニウムには自然な酸化被膜があり、めっきが難しいかもしれませんが、適切な表面処理と前処理を行うことで、ニッケル層はアルミニウムと結合します。これにより、持続的で安定した結果を得ることができる。.

これは黒ニッケルを電気メッキするもので、この方法は金属の周囲に保護層を形成し、摩耗や傷、環境劣化を防ぐのに役立つ。そのため、非常に多様な用途に適しています。黒色電気メッキニッケルの主な用途には、宝飾品、車のトリム、電子ケース、金物、工業用工具などがあります。黒く上品な仕上げは、美しさだけでなく、部品の寿命も延ばします。.

黒ニッケルめっきは、工業用にも装飾用にも使用できます。適切な方法、適切な浴槽条件、適切な後処理により、仕上がりは何年も持続します。黒色電気ニッケルめっきは、保護、耐久性、スタイルを備えた部品を必要とする産業界や趣味家には欠かせないものです。一般的に、黒ニッケルめっきは、便利で魅力的な金属仕上げの両方を求める人々にとって、万能で信頼できる選択肢です。.

よくある質問

Q1: アルミニウムに黒ニッケルをメッキすることは可能ですか?

洗浄、エッチング、亜鉛メッキなどの表面処理を十分に行ったアルミニウムにニッケルメッキを施し、密着性を高めることは可能です。.

Q2: 通常のニッケルめっきと黒ニッケルめっきの違いは何ですか?

ブラックニッケルは濃いマットまたは半光沢仕上げ、標準ニッケルは明るいシルバー仕上げがあります。どちらも耐食性に優れていますが、ブラックニッケルは美観に優れています。.

Q3: 黒ニッケルメッキは家庭でできますか?

小規模なメッキ加工は可能だが、薬品の取り扱い、換気、適切な設備に注意する必要がある。質の高い結果を得るためには、専門家によるサービスが望ましい。.

Q4: 黒色電気めっきニッケルの耐久性は?

黒色電気めっきニッケルは、適切に使用され、密閉されていれば、腐食や摩耗、傷に対して非常に耐性があるため、過酷な条件下でも長年耐えることができます。.

Q5: 後処理は必要ですか?

シーリングや熱処理は、耐久性や耐食性を高め、均一で長持ちする仕上がりを保証します。.