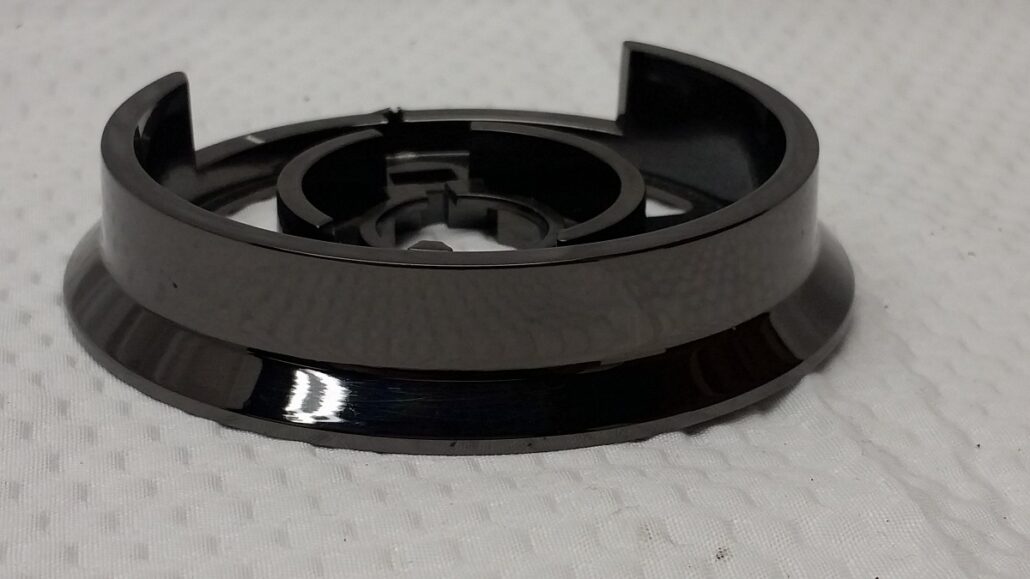

Black nickel electroplating is one of the common ways of finishing, which enhances the appearance and longevity of metal pieces. It gives it a smooth dark appearance and enhances corrosion resistance and hardness of the surface. This has made it popular in most sectors, such as the automotive industry, electronics, jewelry, and ornamental hardware. The question of nickel plating aluminum has been a subject of debate among many novices and experts, as the natural oxide layer on aluminum makes it harder to plate. The nickel layer can fail to stick on efficiently without proper preparation, whereby it can peel or result in an uneven outcome.

The other question that is frequently asked is whether black nickel electroplating is possible at home or in a small workshop. Small-scale arrangements can be made, but professional processes result in more reliable and stable outcomes. Black electroplated nickel is a valuable material because it has a protective value as well as an aesthetic value. The black finish gives a modern and sophisticated appearance to the tools, trims, jewelry, and industrial parts.

In this manual, we shall discuss the entire process of black nickel electroplating. You will get to know the preparation of the surfaces, the plating process, the post-treatment process, and typical pitfalls. At the end, you will know why black nickel is the most used finish in comparison to other finishes and the way it is both functional and decorative.

目次

トグルWhat does Black Nickel Electroplating mean?

The black nickel electroplating is an electrochemical process whereby an alloy of nickel is deposited onto a metal surface. In contrast to conventional nickel plating, the final finish is a dark, matte, or semi-gloss finish. This renders it very much sought after as a decoration. The process also makes the metal surface strong, which makes it less susceptible to scratches, wear, and corrosion.

During aluminum plating, it is more complicated. Naturally, metallic oxide is formed on aluminum, which inhibits the adhesion of the metal. This is the reason why the nickel plating of aluminum must be specially cleaned and pre-treated before applying the black nickel layer. Nevertheless, black electroplated nickel has great protective qualities and a dark appearance as well.

Benefits of Black Nickel Electroplating

耐食性

Corrosion protection is one of the primary reasons why electroplating black nickel would be chosen. The nickel layer protects the underlying metal against the environmental factors, including moisture, salt, and chemicals. This is especially crucial concerning car components, hardware devices, and factory equipment.

Enhanced Surface Hardness

Nickel electroplating black enhances the hardness of surfaces. This enhances wear resistance and reduces scratches on the parts. This additional durability is highly valuable to tools, machine components, and hardware.

Aesthetic Appeal

The black nickel is dark and classy, and the finish is appealing to the eyes. It finds extensive application in decoration, jewelry, car interiors, and electrical casing. Although the conventional nickel plating results in a bright silver appearance, black nickel creates a modern and high-quality appearance.

A Longer Life and Economy

Black nickel plating increases the life of parts by coating them so that they do not corrode or wear out. This lowers the maintenance and replacement expenses and is therefore an affordable solution for both the industries and hobbyists.

汎用性

Black nickel plating may be done on metal, such as aluminum, steel, and brass. This flexibility makes it suitable for a large variety of applications.

Nickel Plating Aluminum Problems

Although nickel plating of aluminum can be done, there are difficulties with it. The natural oxide layer of aluminum is an obstacle to the adhesion of the nickel layer. It is important to clean, etch, and activate the pre-treatment steps to get successful plating. Lack of proper preparation will result in peeling, uneven coverage, or flawed quality of the finish.

The other difficulty is the ability to control the final color. Black nickel electroplating may be darker or uneven when the parameters of the plating are not optimized. It is due to this reason that professional setups are usually suggested for industrial-grade output.

Black Nickel Electroplating Process Step-by-Step

表面処理

Surface preparation must be done properly. Wash the aluminum or other metal to eliminate grease, dirt, and oxidation. In the case of aluminum, the zinc casting step is regularly carried out. This forms a thin layer of zinc, which enhances the adhesion of the nickel. Wash it after cleaning and activation.

電気めっきセットアップ

Warm the black nickel bath using the suggested chemicals and temperature levels. Power supply is needed to deliver the current needed. The workpiece should then be connected as the anode and a cathode material (usually lead or stainless steel) to complete the circuit.

Electroplating Process

Add the metal piece to the black nickel solution. Connect the electric current according to the specifications of the bath. The nickel ions get deposited on the metal surface, forming a dark colored and uniform, and protective coating. Temperature, current, and plating time are to be closely observed.

すすぎと乾燥

Plate. Rinse the part under clean water to cleanse the part of the remaining chemicals. Wipe to avoid water spots or areas that which is unevenly finished.

Post-Treatment

Heat curing or sealing may be done after treatment in order to enhance corrosion resistance and hardness. This is done to ensure that the plated layer is long-lasting and tough.

Uses of Black Nickel Electroplating

Jewelry and Accessories

Jewelry is made to look smooth and modern with the help of black nickel. Both rings, bracelets, and watches enjoy the advantage of being aesthetically appealing as well as corrosion-resistant.

自動車産業

Trims and handles on the car, as well as decorative pieces, are usually black nickel-plated. This offers durability and a high-quality look.

Electronics and Hardware

Electroplating black nickel on electronic housings, switches, and connectors is also aimed at preventing wear and making them more aesthetically attractive.

Industrial Tools

Black electroplated nickel is useful in parts and tools of machines as it enhances the hardness and longevity of the machinery.

Mistakes in Black Nickel Electroplating

Even with expert technicians, it is possible to have problems when nickel-plating aluminum and black plating nickel. Examples of some of the missteps are:

- Inadequate surface cleaning: Dirt, grease, or oil that is present may inhibit sufficient adhesion, resulting in peeling or uneven layers.

- Eliminating pre-treatment of aluminum: The oxide layer on aluminum inhibits plating. When zincating or activation is not done correctly, weak plating is obtained.

- Bath or current temperature: Excessively high temperatures will cause the surface to burn, excessively low temperatures will cause low and weak plating.

- Failure to rinse well after plating: Leftover chemicals will result in streaks, dullness, or corrosion in the long run.

- Omitting sealing or post-treatment: This lowers the corrosion resistance and also lowers the life of the plated part.

It is possible to reduce the quality of electroplating black nickel results by paying attention to these pitfalls.

To Be a Successful Black Nickel Plating

- Clean and open a metal surface constantly.

- In the case of aluminum, it would be necessary to do a zincating step in order to provide adhesion.

- Regulate the plating bath temperature and current to get the same results.

- Streaks can be avoided by using appropriate rinsing and drying methods.

- Take into account professional configurations of large or important parts to guarantee quality.

Advantages vs. Other Finishes

Black nickel is superior to chrome or regular nickel plating in that:

- Dark, elegant aesthetics

- Wear protection and corrosion protection.

- Fitness with aluminum and other metals.

- It has a long life and is low-maintenance.

Although black nickel might fail to give the bright look of chrome, it offers better protection and has a modern appearance, which is well appreciated in most industries.

Materials: Black nickel Electroplating

Base Metals

It is the base metal that is covered with the black nickel coating. Some of the common base metals are aluminum, steel, brass, and copper. Aluminum plating is a highly favored way of nickel plating on the grounds of the light weight of aluminum and its wide application in automobiles, electronics, and the decorative industry. Also, common plating is done on steel and brass so that they become less corrosive and durable to wear. The issue of the base metal is also very important to adhesion and durable outcomes.

ニッケル・ソース

The primary constituent of the plating bath is nickel ions. They are deposited in the base metal when an electric current is used. Typically, the nickel source is nickel sulfate, nickel chloride, or both. These additives provide a homogeneous covering on the electroplated black nickel.

Black Nickel Additives

The black nickel plating process needs certain additives to have the dark look. These can be organic or inorganic compounds that regulate the color, brightness, and uniformity. Additives play a role in the hardness and corrosion resistance of black electroplating nickel. It is important to have proper concentration to attain a uniform and desirable finish.

Electrolyte Solution

The electrolyte solution is the medium that enables the movement of the nickel ions, which are deposited on the base metal. It is generally made up of water, nickel salts, acids, and the black nickel additives. The proper pH and temperature of the electrolyte are the key to uniform plating and avoiding other defects, such as streaks or uneven color.

Cathode and Anode Materials

In the plating process, the base metal is the anode, and a compatible cathode, which normally is stainless steel or lead, is used to complete the circuit. These materials make the process of deposition of black electroplating nickel smooth and even. High-quality electrodes will be selected to minimize contamination and increase the overall quality of the plating.

Comparisons with Other Plating Finishes- Black Nickel

Black Nickel vs Standard Nickel Plating

Black nickel electroplating is used to provide a dark matte or semi-gloss finish, and standard nickel plating is used to provide a bright silver finish. Black electroplated nickel is not only attractive and anti-corrosive, but it is also best suited to ornamental use such as jewelry, automotive trim, and electronic casing. Nickel plating is standard and concentrates more on the protection and the gloss, but does not have the contemporary, stylish appearance of black nickel.

Black Nickel vs Chrome plating

Chrome plating is highly reflective and very hard, yet it may be brittle and easily flake under pressure. On the contrary, when black nickel is electroplated, the layer is flexible and durable. This enhances its effectiveness, particularly on aluminum and lightweight metals. Black nickel is resistant to corrosion and wear, as well as giving an efficient dark look that cannot be made using chrome.

Sturdiness and Resistance to Wear

Both the black nickel and the standard nickel enhance the hardness and durability of the surface. Nevertheless, when the aluminum is plated with nickel black, an additional layer is provided against scratches and oxidation. Dark finish also covers minor wear marks better than shiny nickel or chrome, thus it is useful on tools, handles, and hardware that are handled frequently.

Versatility Across Metals

The nickel electroplating black can be done on a broad variety of metals, such as aluminum, steel, and brass. This renders it more compatible than chrome, which is best used on steel or standard nickel, which needs several coats to be applied. Black nickel plating is used to ensure durability, corrosion resistance, and aesthetics in a single procedure.

Aesthetic Appeal

Lastly, another thing that is considered to be a key benefit of black nickel is its contemporary, sophisticated appearance. Although typical nickel or chrome plating is aimed at the look, the black nickel gives a faint and high-end look. This renders it very popular as both a work and a decorative implementation.

結論

Black nickel electroplating is the most efficient way of improving the beauty and the life of metallic components. It has a smooth, dark appearance and renders much better corrosion resistance and hardening to the surface. Nickel plating of aluminum is a question that many may ask, and although the aluminum has a natural oxide coat, which may make it difficult to plate, with proper surface preparation and pre-treatment, the nickel layer would be bonded to it. This enables sustained and consistent outcomes.

This involves electroplating of black nickel, and this method forms a protective layer around the metals, which helps prevent wear and scratches as well as environmental degradation. This suits it to a great variety of uses. The main applications of black electroplated nickel include jewelry, vehicle trims, electronic cases, hardware, and industrial tools. The dark, classy finish not only adds to the beauty but also to the life of the parts.

Black nickel plating is a solution for both industrial and decorative purposes. Through the proper method, the right conditions in the bath, and proper after-treatment, the finish may last a number of years. Black electroplating nickel is essential to industries and hobbyists who are in need of parts with protection, durability, and style. In general, black nickel plating is an all-purpose and trustworthy option for people who want both useful and attractive metal finishes.

よくある質問

Q1: Is it possible to plate black nickel on Aluminum?

Yes. It is possible to nickel plate aluminum that has been adequately prepared, about the surface preparation, such as cleaning, etching, and zincating, to enhance adhesion.

Q2: What is the variation between the normal nickel plating and the black nickel plating?

A dark matte or semi-gloss finish is available in black nickel, and a bright silver finish is available in standard nickel. They are both superior in corrosion resistance, although the black nickel provides aesthetic value.

Q3: Is it possible to do black nickel plating at home?

Plating on a small scale can be done, but one must exercise caution regarding the handling of chemicals, ventilation, and proper equipment. Professional services are advisable in order to achieve quality outcomes.

Q4: What is the durability of the black electroplated nickel?

Black electroplating nickel is very resistant to corrosion and wear, as well as scratches, when used properly and sealed, and therefore can withstand many years even in severe conditions.

Q5: Should the post-treatment be required?

Yes. Sealing or heat treatment enhances durability, corrosion resistance, as well as guarantees a uniform and long-lasting finish.