The modern automobile is a sophisticated machine that consists of thousands of separate parts with their own purpose to provide safety, performance, and reliability. Casting is one of the various manufacturing processes that are employed in the automotive industry. Casting is now an irreversible procedure where major parts of a vehicle are formed by shaping molten metal into extremely detailed and strong parts. The engines, transmissions, and braking systems of most vehicles are among the most significant systems that require parts made by casting. Indeed, when designers and builders discuss efficiency, durability, and cost-effectiveness in the production, casting of automobile parts are often at the centre stage of the debate.

The art of casting is not new; it was invented thousands of years ago. However, its application in the motor industry has undergone a revolutionary shift to harness hi-tech technologies and the most recent alloys that can fit the high demands of the modern car. Casting has been instrumental in enabling cars to maintain high-performance standards at a relatively low cost through lightweight aluminum engine blocks that are tough and, resilient cast-iron brake components.

The article will review the history of the automobile casting parts, processes, advantages, and future trends of automobile casting parts and reveal the reasons why the automobile casting parts continue to be a pillar in the automotive manufacturing industry.

History of Casting

It was actually the aluminum casting process that penetrated the sphere in the middle of the 20th century. Casting has been in use in vehicles since the late 19th and early 20th centuries, when the automobile was first developed to replace the horse-drawn carriage. Early engines demanded powerful but inexpensive parts, and casting was the right way to go. One of the first methods to make engine blocks, crankshafts, and housings was iron casting.

With the increase in the automobile industry, casting techniques increased and became advanced. The automobile manufacturers learned that they could increase fuel efficiency without reducing the lifetime of the vehicles due to lighter engines and structural parts. Casting is applied to different systems of vehicles in accordance with their application and importance. Finally, the automobile casting parts have the important role of giving strength, accuracy, and cost-effectiveness to reduce the cost, which is why automobile parts are the giants of the automotive industry.

What are Automobile Casting Parts?

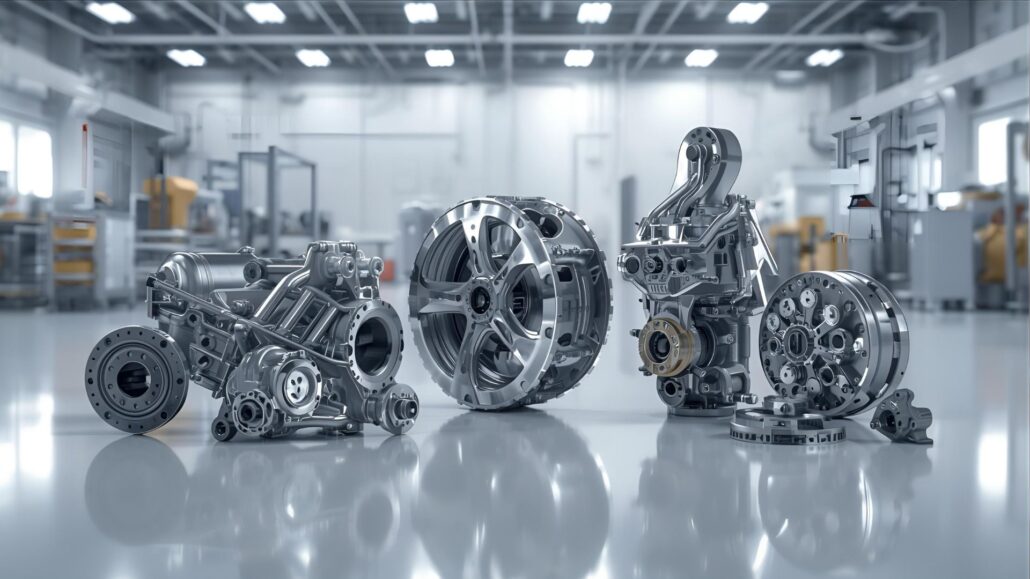

Automobile Casting Parts can be defined as parts of a vehicle that are produced through pouring molten metal into a mold, and the resulting molten metal hardens into a desired shape. This has enabled the manufacture of robust, sturdy, and intricate components that are utilized in automobiles, including engine blocks, cylinder heads, transmission housings, brake drums, and wheels.

They are very popular since casting offers:

- Design flexibility – Detailed geometries can be made.

- Power and resilience – Metals are resistant to intense strain and heat.

- Cost efficiency – Best with mass production.

- Material versatility – It can be made of aluminum, iron, steel, or magnesium.

Taking the case of an engine block, the block has various chambers and coolant passages with threaded openings that can be cast correctly.

Hva er casting?

The process of casting is a type of manufacturing where molten metal is poured into a mold and allowed to cool in the shape of the mold. After cooling, the casting is removed, machined (where needed),, and fitted into the finished product. It is an operation in which it is possible to produce both strong and geometrically complex parts.

The reason why automobile manufacturers like to use casting is that they can produce large quantities of complicated parts of uniform quality. The proper melting temperature should also be maintained to remove defects such as porosity or underfill

We are discussing not only structurally significant parts of automobiles, but also those that must be precise and durable under severe conditions of high temperatures, pressures, and constant wear.

Process of Casting in Automobile Parts

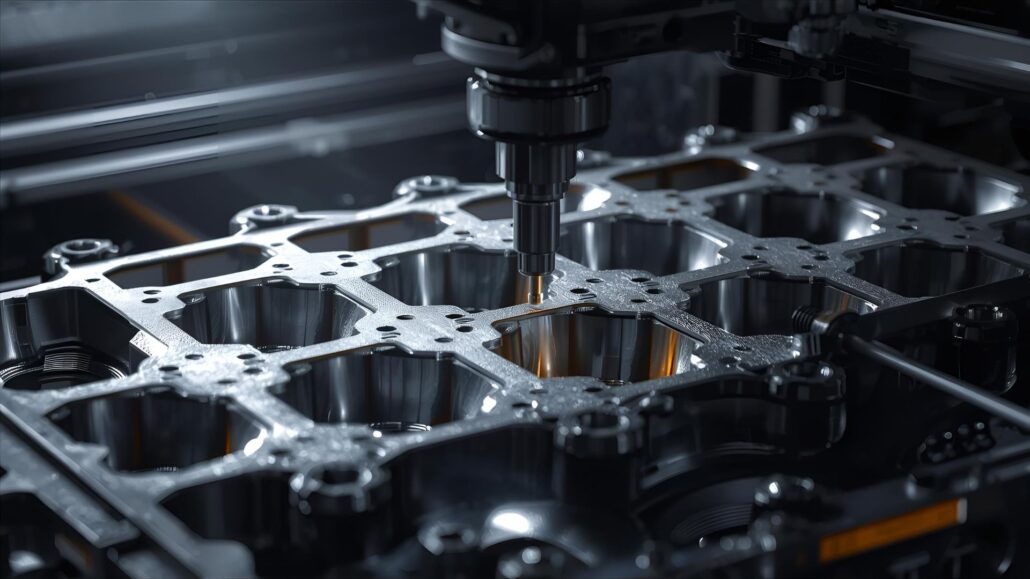

High-volume production also automates machines or high-pressure systems to ensure a high level of accuracy and consistency.

1. Pattern Making

It starts with the production of a pattern, an imitation of the finished part. Patterns tend to be made of wood, metal, or plastic. They also determine the accurate shape and size of the mold cavity into which the molten metal will be poured.

2. Mold Preparation

Sand, metal, or ceramic materials are used to form a mold. The two halves of the mold make the cavity to shape the part. Hollows can also be introduced within the mold,, such as internal passages within an engine block.

3. Melting the Metal

In a furnace, a controlled temperature is used to melt the selected metal or alloy (cast iron, aluminum, or magnesium). This is to bring mechanical properties to high-performance applications such as engines or gearboxes.

4. Pouring

When the metal is melted, it is filled into the mold. The proper sizes and finishes are ensured during drilling, milling, and turning.

5. Størkning og avkjøling

The heated material is left to cool and harden within the mold, assuming the shape of the mold. The part should avoid a shrinkage defect or crack due to uncontrolled cooling rates.

6. Mold Removal

When solidifying, the mold is broken (in sand casting) or the mold is opened (in permanent and die casting). A raw casting is then removed and processed further as a casting blank.

7. Fettling and Cleaning

Unneeded material, including sprues, risers, or flash, is eliminated. The casting could be shot blasted or ground to clean up the surface to make it easy to machine.

8. Heat Treatment (if required)

Cast parts can be heat-treated to enhance their strength, hardness, or toughness. Sand Casting – Sand casting is one of the oldest and most common ways in which a mold of sand is molded into a more complicated shape.

9. Machining and Finishing

Despite the fact that casting generates near-net shapes, a lot of automobile parts have to be machined to be precise. It is used with the engine block, cylinder head, and manifold.

10. Inspection and Testing

Lastly, quality checks are done on the cast part. Non-destructive testing (NDT), dimensional testing, and material inspection are conducted to ensure that the part is up to industry standards before assembly into a vehicle.

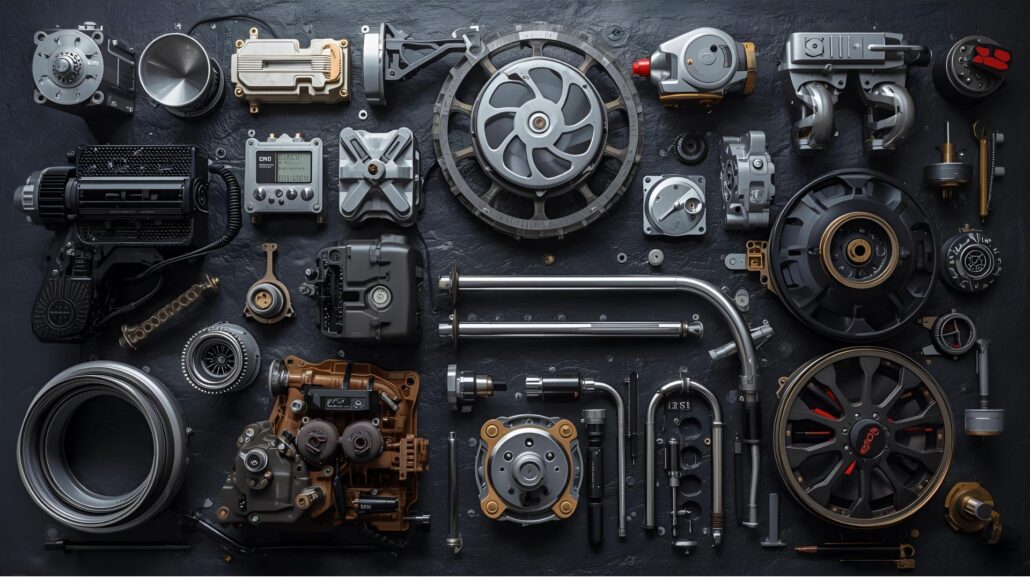

Types of Casting Methods Used in Automobiles

There are several methods of casting that are employed in automobiles.

- Die Casting – This technique involves subjecting molten metal to a steel mold with great pressure to create parts with a smooth finish and free of dimensional errors. Die casting is commonly used to make lightweight aluminum and magnesium components.

- Investment Casting – Investment casting is also known as lost-wax casting, and can be highly accurate in smaller components such as gears, brackets, etc.

- Centrifugal Casting – This is applied mainly to cylindrical components such as bushings and sleeves, and the result is a dense and defect-free part.

- Permanent Mold Casting – Includes reusable molds which offer better accuracy than sand casting, but are less expensive than die casting.

Automakers choose the casting process in accordance with material, design, performance requirements, and volume of production.

Casting Materials Automobile

Støpejern

The use of cast iron is one of the more traditional and most frequent materials of automobile casting. It has good wearing qualities, strength, and can withstand high temperatures. Usages include cylinder heads, gearbox housings, and wheels etc.

Aluminiumslegeringer

Aluminum alloys are also sought after in the automobile industry because they are light and impervious to corrosion. Steel alloys are normally tough and strong enough to be utilized in components that are under a lot of stress and load. This is used on standard gears, crankshafts, and suspension parts.

Steel Alloys

They provide an excellent weight-to-force ratio and can hence be used as transmission cases, steering wheels, and dashboard supports. Steel is heavier than aluminum, but it remains very reliable in challenging conditions. Copper alloys such as bronze and brass are not widely used, but are highly wear and corrosion-resistant.

Magnesiumlegeringer

Magnesium alloys weigh even less than aluminum and are also becoming more popular in modern cars, where saving weight is a major concern. They are mainly applied in smaller precision products like bearings, bushings, and fittings, in which long life is required.

Copper Alloys

Copper alloys such as bronze and brass are not widely used, but are very resistant to wear and corrosion. They are mostly applied to smaller precision products like bearings, bushings, and fittings, where long life is required.

Manufacturers frequently emphasize the fact that the automobile casting components manufactured with the use of these materials may resist the harshest mechanical factors and be rather inexpensive.

The following is a comparison table of automobile casting part materials:

| Materiale | Viktige egenskaper | Fordeler | Typiske bruksområder |

| Støpejern | High durability, excellent wear resistance, withstands high temperatures | Affordable, durable, ideal for high-temperature parts | Engine blocks, brake drums, cylinder liners |

| Aluminiumslegeringer | Lightweight, corrosion-resistant, good thermal conductivity | Reduces vehicle weight, improves fuel efficiency | Cylinder heads, gearbox housings, wheels |

| Steel Alloys | High strength and toughness, durable under stress | Suitable for heavy-duty components requiring high strength | Gears, crankshafts, suspension parts |

| Magnesiumlegeringer | Very lightweight, good strength-to-weight ratio | Improves efficiency with lighter components | Transmission cases, steering wheels, dashboard supports |

| Copper Alloys | Corrosion resistance, good wear properties | Long-lasting in corrosive environments, good for precision | Bushings, bearings, small fittings |

Cast Major Auto Parts

Casting is a crucial aspect of manufacturing numerous critical auto parts that are critical. Some of the most critical are:

Engine Blocks

- One of the most widespread casting uses.

- Typically cast iron or alloys of aluminum.

- Should be able to withstand high heat, pressure, and vibration.

Cylinder Heads

- Normally made with the casting of aluminum to make them lighter.

- House intake/exhaust valves, spark plugs, and coolant passages.

Transmission Housings

- It consisted of light and strong alloys of aluminum or magnesium.

- Shield and guard the gears and shafts within the transmission.

Brake Drums and Discs

- Frequently made of iron because it is heat-resistant and long-lasting.

- Of paramount importance to vehicle safety about high levels of friction and temperatures.

- Intake manifold (IM) and Exhaust manifold (EM).

- Sand cast because of the complexity of their shapes.

- Spread airflow or exhaust gases inside the engine system.

Suspension Components

- Control arms, brackets, among others, are normally cast so that they can be both strong and reliable.

- Has to be subjected to constant road pressures.

Wheels (Alloy Wheels)

- Typically cast in aluminum.

- Strength, beauty, and a decrease in total weight.

- Crankshafts and Camshafts (in certain ones)

- Can be cast before being machined.

- Precision and hardness of demand on engines and the transmission of power.

All these illustrations show how the automotive industry depends on automobile parts manufactured through casting to provide performance and durability.

Viability and Reliability

Manufacturers like casting, rather than other manufacturing methods, for several reasons:

Design Flexibility

With casting, it is possible to create parts of an automobile with complex shapes and fine details. Other features such as thin walls, internal cavities, and complex passages can be made directly in the mold and minimizing additional machining and saving production time.

Styrke og holdbarhet

Castings of automobile parts are powerful and durable. Considerable toughness- cast iron, aluminum, and steel materials are tough enough to withstand intense heat, heavy loads, and constant vibration. This is required in the automobile industry, and all automobile components are of standard and safe quality.

Kostnadseffektivitet

After creating a mold, one can then cast thousands of parts that are the same at a relatively low cost. This makes it one of the least costly ways of producing large quantities of automotive parts in a batch.

Lightweight Options

Lightweight alloys such as magnesium and aluminum are also supported by casting. The materials reduce the overall weight of vehicles, improving fuel efficiency and reducing emissions with no resultant reduction in structural strength.

Versatility in Materials

Many different metals can be cast. Based on the purpose of the part (high strength, corrosion resistance, lightweight), automakers can choose the most appropriate alloy.

The Smallcasting Technology Today

In modern casting techniques, the results are reproducible within batches of parts. Manufacturers are frantically attempting to remove such constraints by applying superior techniques, including vacuum casting and computer simulations.

According to automotive scientists, the automobile casting components are often stronger and less expensive, and, therefore, they are the only viable solution.

Disadvantages and problems of Casting

There are also problems with casting, although they are not so advantages:

Defects in Castings

The casting defects are one of the greatest issues in casting. The final component can be weakened by problems like porosity, cracks, shrinkage cavities, and inclusions. These flaws can require additional testing and quality assurance to ensure that the component is safe.

Need for Machining

Despite the near-net shapes produced by casting, most components still need to be machined to become precise. Bearing seats, bolt holes, and sealing areas should be finished to a tight tolerance. This additional measure adds time and cost to production.

Material Limitations

Not every metal is very much casting-suitable. Other alloys are hard to pour, are likely to crack, or do not offer the preferred strength. This restricts the selection of materials in some automobile components and even compels manufacturers to seek other ways.

High Energy Consumption

Casting is also a high-temperature process that consumes a lot of energy as it melts the metals. This renders the casting process energy-intensive as compared to other production processes, which poses a cost and environmental concern.

Environmental Concerns

Besides the energy consumption, casting also produces emission wastes such as used sand, slag, and furnace melting emissions. They have an even more difficult time dealing with these by-products, with automakers moving towards manufacturing processes that are more environmentally-friendly.

Casting Technology Today

The casting technology is designed to meet the requirements of electric cars and sustainability:

- Automated Casting Systems – save wastage and increase precision.

- Mold 3D printing – Faster prototype development.

- High-Performance Alloys – Stronger and weigh less than the ordinary ones.

- EV integration – EVs Large single-piece aluminum castings (occasionally referred to as giga-castings) are currently utilized in the production of the chassis of electric vehicles.

Innovators point out that parts of automobiles produced through casting are changing with the new generation of vehicles.

Technical Comparison of Material used in Automobile casting

A rather technical table of Materials Used in Automobile Casting, here is an expanded version with the most important engineering properties, benefits, and usage:

| Materiale | Tetthet (g/cm³) | Strekkfasthet (MPa) | Thermal Conductivity (W/m·K) | Viktige fordeler | Typiske bruksområder |

| Støpejern | 6.9 – 7.3 | 150 – 400 | 40 – 55 | High wear resistance, good vibration damping, withstands high heat | Engine blocks, brake drums, cylinder liners |

| Aluminiumslegeringer | 2.6 – 2.8 | 200 – 400 | 120 – 160 | Lightweight, corrosion-resistant, good machinability | Cylinder heads, gearbox housings, wheels |

| Steel Alloys | 7.7 – 7.9 | 400 – 1200 | 15 – 60 | Very strong, high toughness, fatigue resistance | Crankshafts, gears, suspension components |

| Magnesiumlegeringer | 1.7 – 1.9 | 150 – 300 | 70 – 90 | Extremely lightweight, good strength-to-weight ratio | Transmission cases, steering wheels, dashboard parts |

| Copper Alloys | 8.7 – 8.9 | 200 – 500 | 300 – 380 | Excellent wear resistance, high thermal & electrical conductivity | Bearings, bushings, small precision fittings |

It is in technical/engineering form with the numerical properties (density, tensile strength, thermal conductivity), advantages, and applications.

Miljøhensyn

The automotive industry has developed an interest in sustainability. Casting is an energy-consuming process; however, recycling and improved melting techniques are minimizing its effects on the environment. The amount of energy used to recycle aluminum, such as recycled metal, is much less than that used to make new metal.

The goal in green manufacturing is to ensure that the so-called automobile casting parts not only become durable, but also environmentally friendly.

Fremtidsutsikter

The future of automotive casting looks good. Electric vehicles are coming up, which means that lightweight, but powerful parts are needed more than ever. The use of large støpt aluminium parts is minimizing the number of parts involved in the manufacture of car assemblies, and producing them faster and with less cost.

There, too, the growth will be driven by emerging markets, because the affordable and durable manufacturing techniques are needed to produce vehicles in large numbers.

Konklusjon

Since the automobile industry was introduced, casting has been the main industry in automobile manufacturing and still remains that way today. The automotive world could not have been what it is today without cast parts (engine blocks, suspension parts, etc.). Casting will continue to be one of the most significant processes in the automotive industry with modern innovations, sustainable practices, and inclusion in the production of electric vehicles.

In brief, the dependence on automobile parts produced through casting can also show that a time-proven procedure is able to adjust itself to the requirements of the new century and its challenges. Likewise, the power, economic nature, and versatility of the so-called automobile casting parts make them a legend of the current and future transportation.

Vanlige spørsmål

1. What are cast auto parts?

Casting auto parts are elements created by pouring liquid metal into a mold, and it hardens to form the desired shape. It is used extensively to manufacture engine blocks, cylinder heads, transmission housings, brake parts, and wheels.

2. So what is so important about casting in the automobile world?

One of the reasons why casting is important is that it enables complex and durable parts to be produced in large quantities at a comparatively low cost. It is also flexible in design, allows lightweight alloys to be used, and provides uniformity in large production quantities.

3. What are the typical automobile casting parts materials?

The most popular ones are cast iron, alloys of aluminum, steel alloys, alloys of magnesium, and alloys of copper. Every material will be selected according to the performance of the component, like the strength, weight or wear, and heat resistance.

4. What are the advantages of casting on auto parts?

The advantages of casting include design freedom, low cost, high strength and durability, light-weight alloys may be used, and consistent quality in high-volume manufacturing. This has made it a favorite way of producing important parts of the automobile.

5. What are the most important issues or limitations with in-car casting?

The casting defects (porosity or cracks), additional machining to achieve accuracy, limitation of the material, high-energy usage, and environmental problems caused by emissions and waste products are the key challenges.