Selecting an appropriate aluminum die-casting service provider is a critical decision for car manufacturers. Aluminum die casting has been at the forefront of producing light, high-strength, dimensionally accurate parts that comply with stringent current fuel-efficiency, safety, and emissions requirements. Despite the acknowledged performance advantages of aluminum alloys, the final quality of automotive components still depends on the supplier’s skills, technologies, and quality systems.

Due to the change in the automotive industry to the production of lighter cars and electric mobility, the need to find a reliable aluminum die-casting partner is growing. Tier 1 suppliers and OEMs do not intend to focus solely on price. They consider factors such as suppliers’ engineering capacity, manufacturing reliability, certifications, overseas experience, and the potential for long-term cooperation.

The article points out three notable die casting service firms based in China, including GC Precision Mold (Aludiecasting), CNM Casting, and Sincere Tech, and five widely known aluminum die casting firms in other parts of the world. These companies are the most reputable brands in international odlew aluminiowy for the automotive sector.

Spis treści

ToggleAluminum Die Casting in the Auto Industry: Overview

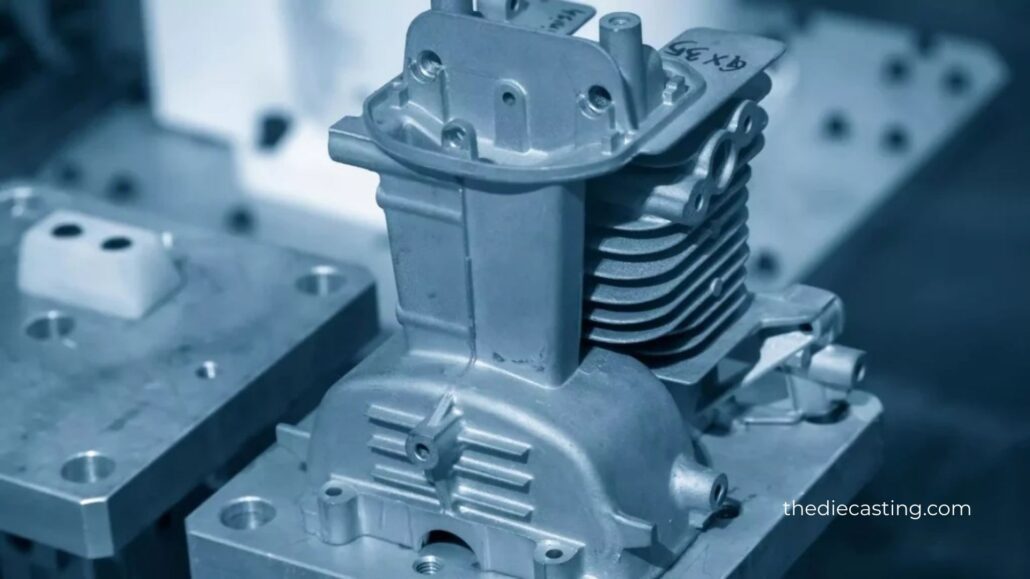

Aluminum die casting is a high-pressure production process whereby molten aluminum alloy is forced into a hardened steel mold, producing complex parts with high dimensional accuracy and surface finish. Die casting is used to produce high volumes with tight tolerances, unlike other forming methods, which is why it is widely used in the automotive industry.

Automotive manufacturers increasingly use aluminum for its low weight, corrosion resistance, and strong mechanical properties. Other components typically produced by aluminum die casting include engine housings, transmission cases, motor housings, structural brackets, battery enclosures, and chassis components. The use of aluminum die casting has also increased in electric vehicles, as they require balancing bulky battery packs.

Nevertheless, the unique thermal and flow properties of aluminum require specific tooling design, controlled casting parameters, and advanced quality control. That is why automotive project editions require selecting an experienced, skilled aluminum die-casting service provider.

Aluminum Die Casting- Auto Market

The global automotive aluminum die-casting market has been growing steadily. As of 2025, the market is valued at USD 31.27 billion and is expected to exceed USD 41 billion in 2029, with a compound annual growth rate of over 7%. The emergency increase is driven by policies such as lightweighting, more stringent emissions standards, and the adoption of electric vehicles.

China has been the world’s largest hub for aluminum die-casting production, with a well-developed manufacturing infrastructure, strong supply chains, and economies of scale. Meanwhile, its global partners, including Europe, Japan, Korea, and North America, continue to lead in innovation across large structural castings, automation, and sustainability.

Aluminum Die Casting Service Companies Specifications

State of the Art Die Casting

By 2025, the best suppliers of odlew aluminiowy services will have been those that have the capability of producing the required components of the automotive systems accurately. They offer various casting methods, including high-pressure, low-pressure, and vacuum-assisted die casting, enabling manufacturers to produce lightweight parts with high strength and minimal defects. These capabilities are required for engine and structural parts and for safety-critical applications.

Contemporary Technology and Machinery

The major suppliers invest heavily in modern die-casting machines, automation, and simulation. Analysis of mold flow and real-time process monitoring helps ensure production stability and quality consistency. Modern casting technology also enables large, single-piece aluminum production, saving assembly time and reducing vehicle weight.

Custom Design and Support for Manufacturing

Leading aluminum casting firms offer comprehensive solutions, including design and engineering analysis, prototyping, and mass production. This combined methodology ensures design optimization, functionality, and flexibility to meet OEM and supplier needs.

Quality Control and International Certifications

Leaders in an industry are characterized by strict quality control. IATF 16949 and ISO standards, and X-ray and CMM tests are all the certifications that guarantee that each component meets the international safety and performance standards.

Customer Support and Cost Effectiveness

Their strong technical support, effective communication, and reasonable pricing make these vendors strong long-term partners for automotive manufacturers worldwide.

Top-Rated Aluminium Die Casting Service Providers

GC Precision Mold (Aludiecasting.com) -China

Aludiecasting, or GC Precision Mold, is a reputable automotive and industrial die-casting service provider of aluminum die castings in China. The company, founded in 1999 and headquartered in Dongguan, Guangdong Province, has built a strong reputation for providing a comprehensive, end-to-end die-casting solution.

Aludiecasting specializes in aluminum alloys, including ADC12, A380, A360, and A356. Its services include designing molds, high-pressure die casting, CNC machining, surface finishing, and final assembly. The company can handle not only small parts requiring high accuracy but also larger automotive components, using modern die-casting machines up to large-tonnage machines.

Aludiecasting has a major strength: a vertically integrated manufacturing model. The company retains tooling, casting, machining, and finishing under one roof, enabling it to tightly control quality, cost, and lead time. This makes it a partner of choice for automotive customers seeking a reliable production partner and competitive pricing.

CNM Casting (diecastingschina.com)-China

Another reputable aluminum die-casting service provider in China is CNM Casting, with over 20 years of industry experience. The company provides die casting in aluminum, zinc, and magnesium for automotive, lighting, electronics, and industrial equipment manufacturers.

The key strength of CNM Casting is its adaptive production strategy. In addition to die casting, the company offers CNC machining, surface finishing, and design optimization services. Automotive customers appreciate that CNM can facilitate product development by enhancing mould efficiency and minimizing waste.

The company places a strong emphasis on quality assurance; in this case, inspection tools include CMM measurements, dimensional testing, and surface quality checks. CNM Casting would be best suited to small- to medium-sized automotive initiatives, where cost-effectiveness and engineering guidance are equally important.

Sincere Tech (plas.co / plasticmold.net) -China

Sincere Tech is a flexible production firm that provides aluminum die casting, plastic injection molding, and CNC machining. Sincere Tech, based in Dongguan, China, has gained popularity among customers seeking flexibility, rapid prototyping, and small production runs.

Sincere Tech specializes in precision aluminum component housings, brackets, and functional parts for automotive applications. The company excels at handling complex designs, tight lead times, and low-volume production, making it a strong partner for start-ups, R&D, and customized motor parts.

Sincere Tech integrates die casting with in-house tooling and machining to deliver a streamlined manufacturing process for its automotive customers, enabling them to bring products to market more quickly.

Best Global Die Casting Aluminum Companies

Nemak – Mexico / Global

Nemak is a leading die-casting company in the automotive industry. Nemak has dozens of manufacturing facilities across Europe, Asia, and the Americas, with its headquarters in Mexico. The company supplies engine blocks, cylinder heads, structural components, and EV battery casings.

Nemak boasts superior casting technologies, including high-pressure die casting, low-pressure casting, and gravity casting. Its robust R&D and international OEM alliances make it a leader in high-volume automotive aluminum casting. It is an excellent choice for making automotive parts and providing services.

The company provides services to four-wheeler dealers. If the buyer is looking for two-wheeler deals, they should not consider this option.

Ryobi Limited – Japan

Ryobi Limited is a long-established Japanese company engaged in aluminum die casting for the automotive industry. The company specializes primarily in high-pressure die casting and operates highly automated production plants in Asia, Europe, and North America. The company has been in business since 1943.

Ryobi is reputed to manufacture high-precision automotive parts with high consistency, making it a valued supplier to global automotive brands. The company is known for manufacturing tools and hardware.

GF Casting Solutions Switzerland

GF Casting Solutions is a high-quality aluminum and magnesium casting company headquartered in Switzerland. The firm supplies the automotive, aerospace, and energy industries and focuses on lightweight design and sustainability.

GF Casting Solutions is highly invested in research and development and produces complex, high-performance automotive components that require stringent quality standards.

Sungwoo Hitech – South Korea

Sungwoo Hitech is a major South Korean automotive parts manufacturer specializing in aluminum structural components and body-in-white assemblies. The company collaborates with leading OEMs and operates worldwide across Asia, Europe, and North America. The company is famous for making structural components. It has an R&D team for research and development. They are a major contender in the automotive market, specializing in lightweight vehicle construction.

Wnioski

Choosing an appropriate aluminum die-casting service provider is critical for high-volume automotive component production. Although the industry is dominated by global players such as Nemak, Ryobi, and GF Casting Solutions, which are more in terms of size and innovation, the manufacturers based in China, namely GC Precision Mold (Aludiecasting), CNM Casting, and Sincere Tech, are exceptional in terms of value integration, flexibility in production, and cost effectiveness.

The companies described in this paper have their own strong points. Ultimately, the most appropriate option will depend on the project size, technical requirements, cost, and long-term manufacturing objectives. By collaborating with a reputable aluminum die-casting service provider, automotive producers can enhance product quality, reduce costs, and remain competitive in a fast-changing market.

If you need a reliable aluminum die casting supplier for automotive components, Aludiecasting is ready to assist with your project, delivering with accuracy, quality, and efficiency.

Często zadawane pytania (FAQ)

What is the meaning of aluminum die casting, and why do we use it so much in manufacturing automotive?

Die casting is a high-pressure production process in which molten aluminum alloy is forced into a steel mold to produce complex, accurate parts. It is also widely used in motor vehicle production because aluminum is lightweight, strong, corrosion-resistant, and suitable for mass production. These advantages enable automakers to reduce vehicle weight, improve fuel efficiency, and meet stringent emissions standards.

What are the common automotive components that are made using die casting of aluminum?

Aluminum die casting is used to manufacture many critical automotive components. These are engine blocks, transmission housings, cylinder heads, oil pans, motor housings, battery enclosures in EVs, brackets, frame, and structural body parts. The process is favourable to both electric and traditional vehicles.

What is the best way to select an aluminum die casting service provider?

Selecting the appropriate provider depends on experience, production capacity, certifications, and technical capabilities. Find automotive experience, modern equipment, IATF 16949/ ISO, high-quality control systems, and effective communication support in the entire project life cycle.

What is the reason why such alloys as aluminum A380 and ADC12 are used in die casting?

Alloys like A380 and ADC12 are preferred because they are highly castable, strong, have good thermal conductivity, and provide a good surface finish. The A380 is highly durable and dimensionally stable, whereas the ADC12 is better suited to more complex geometries and high-volume production.

Can Chinese automotive die-cast parts companies be trusted?

Yes, Chinese aluminum die-casting firms are known worldwide for their quality and cost-effectiveness. They offer high-level automation, robust supply chains, rapid prototyping, and competitive pricing, all while upholding international quality standards.

What role does the die casting of aluminum play in the manufacturing of electric vehicles?

Electric vehicles require lightweight, high-power components to offset battery weight. Die-cast aluminum is the most suitable material for manufacturing battery, motor, and inverter casings, as well as structural components, making it critical to EV production.

Why is Aludiecasting a competitive aluminum die-casting service provider?

Aludiecasting provides a one-stop service, including mould design, die casting, CNC machining, surface finishing, and quality checks. Its competitive pricing, experience across multiple industries, and stringent quality control make it a strong option for automotive aluminum die casting.

Why is China the preferred destination for many automotive companies in Aluminum Die Casting?

Since China is economically strong, highly integrated in its supply chain, and capable of producing large quantities of aluminum die castings, it has become a preferred location for these services. Chinese manufacturers such as Aludiecasting, CNM Casting, and Sincere Tech will provide competitive pricing without compromising quality.

Raw materials and high automation, coupled with rapid tool development, enable Chinese manufacturers to offer shorter lead times and greater production flexibility. Numerous Chinese die-casting firms offer one-stop solutions, which simplify automotive customers’ operations and reduce supply chain risk.