Índice

AlternarFundição sob pressão de hardware: Um guia completo para a fabricação moderna

O ambiente competitivo moderno no setor de manufatura colocou as indústrias sob pressão contínua para fabricar componentes de hardware que sejam robustos, resistentes, precisos e econômicos. Para atingir esses objetivos, as empresas usam métodos de produção contemporâneos que são eficientes e de qualidade. Um dos processos mais bem-sucedidos e populares é a fundição sob pressão de hardware. Os fabricantes são capazes de criar componentes de hardware que reúnem detalhes complexos com excelente resistência, colocando metal fundido sob alta pressão em um molde feito de aço. Esse processo é usado para produzir elementos com acabamento suave e qualidade uniforme, além de produzir um número significativo de elementos a um preço unitário razoavelmente baixo.

A relevância da fundição sob pressão de hardware é muito difundida em uma série de setores. Ela é usada no setor automotivo na fabricação de componentes leves, mas resistentes, que resultam em eficiência e segurança de combustível. Pode ser usada na eletrônica para fabricar carcaças, conectores e dissipadores de calor sustentáveis. As peças de precisão são vantajosas para as empresas aeroespaciais, pois podem resistir a condições adversas, mas os setores de construção e móveis as utilizam em seus acessórios funcionais e decorativos.

O artigo será uma investigação completa do processo de fundição de ferragens e seus benefícios, processo e materiais. Também analisaremos a posição do hardware de fundição de alumínio, as vantagens distintas do uso de fundição sob pressão de zinco e os crescentes usos das várias peças de hardware de fundição sob pressão nos setores atuais.

O que é Hardware Die Casting?

A fundição de hardware é um método de fabricação especializado que envolve moldes de aço, ou seja, moldes chamados de matrizes, para formar peças de metal. Isso é feito derretendo-se metais como alumínio, zinco ou magnésio e, em seguida, forçando o metal derretido em uma cavidade de molde sob alta pressão. Após o endurecimento do metal, o molde é aberto e o componente é forçado a sair.

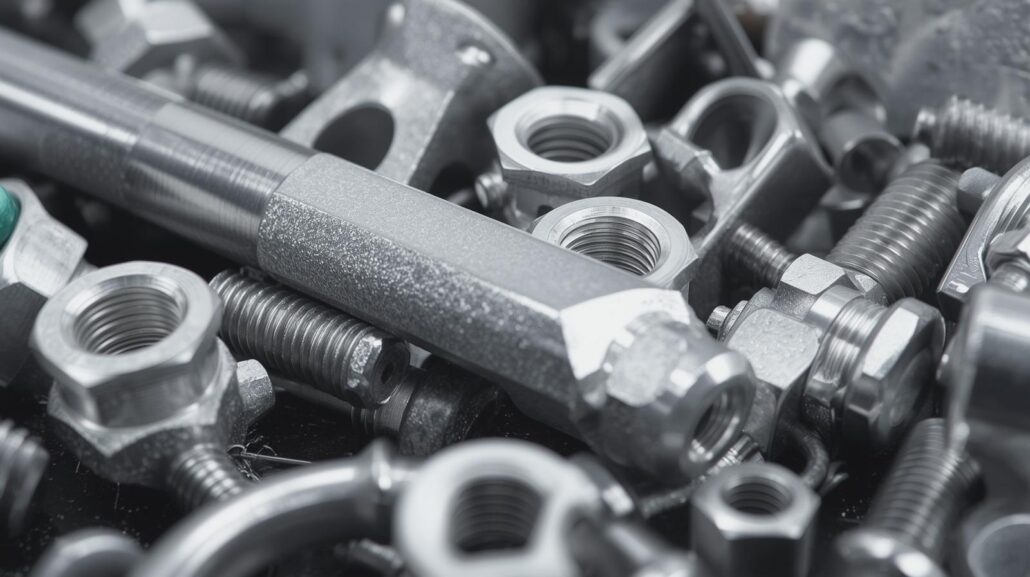

A palavra hardware usada aqui significa peças menores, porém vitais, como dobradiças, suportes, maçanetas e fechaduras, entre outros acessórios. Com a fundição em matriz, os produtos são uniformes, resistentes e econômicos, em contraste com outros métodos tradicionais de produção, como forjamento ou usinagem.

O processo de fundição de hardware

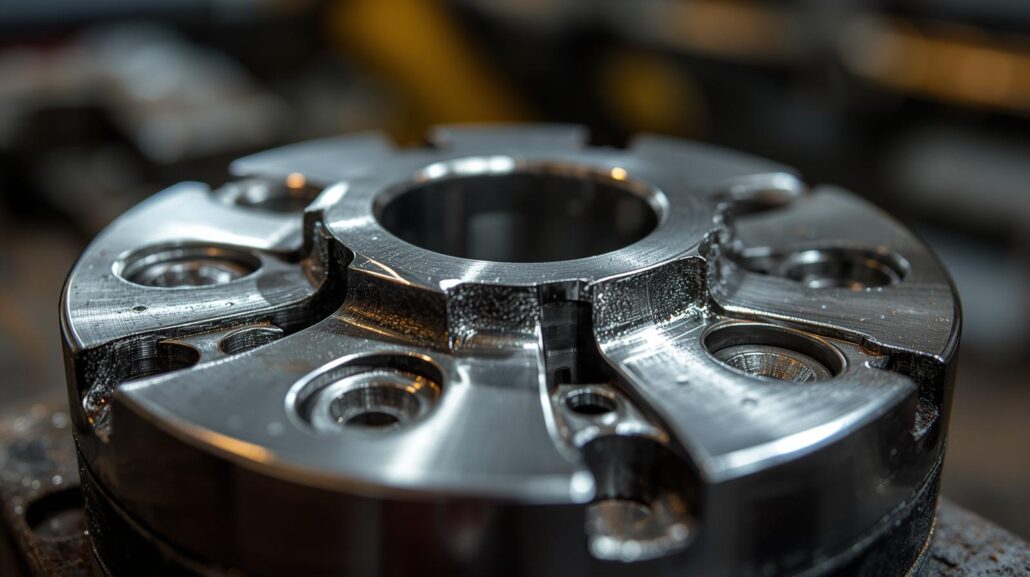

Projeto e preparação do molde

Fundição de hardware sob pressão - O processo de fundição sob pressão começa com o projeto e a preparação do molde ou matriz. Um molde é projetado por engenheiros usando aço de alta qualidade, que é duro o suficiente para suportar um número maior de ciclos de injeção de metal fundido. As duas metades do molde são então moldadas e montadas para criar uma cavidade na qual a peça será moldada. Para ser eficiente, o molde terá canais de resfriamento embutidos para manter sua temperatura e pinos ejetores, que permitirão que ele seja facilmente liberado depois de solidificado.

Derretendo o metal

Quando o molde está pronto, o metal escolhido é derretido em um forno a temperaturas bem monitoradas. O alumínio e o zinco são os mais usados, e é importante manter o estado fundido adequado. A temperatura constante permite que o material fundido em fluxo preencha o molde sem formar defeitos e bolhas de ar.

Injeção na matriz

Depois de colocar o metal no estado fundido correto, ele é forçado a entrar na cavidade do molde com uma pressão extremamente alta que pode variar entre 1500 e 25000 psi, dependendo do material a ser usado e da complexidade do projeto. É um método de injeção de alta pressão, que garante que todas as seções do molde sejam preenchidas até o último detalhe, e o resultado é extremamente preciso.

Resfriamento e solidificação

Assim que o metal fundido entra no molde, ele começa a esfriar e endurecer. Esse processo precisa ser bem regulado, pois o resfriamento rápido ou lento pode levar a alterações na qualidade do produto final em termos de resistência e precisão. Quando um ciclo de resfriamento adequado é mantido, os componentes de hardware serão potentes e dimensionalmente precisos.

Ejeção e acabamento

Quando a peça está sólida, o molde é aberto e o componente é literalmente ejetado por pinos ejetores. É nesse momento que o produto é moldado, mas há excesso de material, comumente chamado de flash. Esse excesso é removido e a parte pode ser submetida a outros processos de acabamento, como polimento, anodização ou revestimento, para melhorar a aparência e a capacidade de trabalho. O ciclo pode ser repetido continuamente e os fabricantes podem fabricar um grande número do mesmo tipo de peças de hardware de fundição sob pressão com eficiência muito alta.

Benefícios da fundição sob pressão de hardware

Precisão e exatidão

Entre os aspectos positivos mais importantes da fundição sob pressão de hardware está a alta precisão que o processo pode proporcionar. Projetos complicados e com tolerâncias rígidas podem ser gerados no processo, o que pode evitar usinagem adicional ou até mesmo eliminá-la completamente. Essa precisão significa que todos os componentes se encaixam em seu uso, seja em um veículo, um produto eletrônico ou hardware de construção. Os fabricantes também gostam do fato de poderem criar formas complexas no mesmo processo, em vez de usar vários processos de fabricação.

Resistência e durabilidade

Os metais fundidos sob pressão são reconhecidos por sua forte capacidade mecânica e excelente resistência. Os componentes de hardware fabricados sob o processo de fundição sob pressão de hardware são capazes de suportar peso elevado, aplicações repetidas e sujeitos a desgaste sem que sua funcionalidade seja afetada. Essa é a razão pela qual essas peças tendem a ser aplicadas nos setores mais confiáveis, como o automotivo e o aeroespacial. Sua durabilidade também implica a redução da necessidade de substituição de produtos, o que agrega valor para o fabricante e para os usuários finais.

Econômico ao lidar com grandes quantidades

O processo de fundição é muito barato quando a produção em massa precisa ser feita depois que a matriz foi produzida. As empresas podem fabricar milhares ou milhões de peças do mesmo tipo com uma variação muito pequena. Essa capacidade de produzir em grande escala e a um baixo custo por unidade está entre os fatores que tornam a fundição de hardware mais desejável em comparação com outros processos, como forjamento ou usinagem. A fundição sob pressão oferece uma solução impecável para os fabricantes que precisam comprometer a qualidade com preços mais baixos.

Qualidade da superfície

A outra vantagem importante é a qualidade do acabamento da superfície durante a fundição. Os componentes fundidos sob pressão de hardware geralmente têm superfícies lisas e homogêneas que não precisam de muito ou nenhum processamento adicional. Isso os torna ideais para revestimento, pintura, anodização ou galvanização com base na funcionalidade e nas exigências estéticas do produto final. O alto acabamento não apenas melhora a aparência, mas também oferece resistência a qualquer corrosão e desgaste.

Eficiência do material

A fundição sob pressão está entre os processos de fabricação mais eficientes em termos de material. A precisão associada à injeção do metal fundido na matriz significa que o desperdício de material é mínimo. Mesmo as menores quantidades de conteúdo redundante podem ser reutilizadas e recicladas e, portanto, o processo é ecologicamente correto e econômico. Esse é especialmente o caso dos setores hoje em dia, onde a sustentabilidade está se tornando uma prioridade.

Versatilidade de design

Além das vantagens clássicas, outro benefício significativo da fundição sob pressão de hardware é sua flexibilidade. O processo permite que os engenheiros criem componentes de praticamente qualquer formato ou forma, incluindo projetos complexos, paredes finas e detalhes finos difíceis de criar usando processos alternativos. Essa flexibilidade também permite que os fabricantes sejam mais inovadores e desenvolvam hardware para atender aos requisitos de funcionalidade e estética.

Velocidade e eficiência

A fundição sob pressão também é apreciada em relação à velocidade. O ciclo completo do processo de injeção, resfriamento e ejeção pode levar alguns segundos ou minutos, dependendo do tamanho da peça. Isso resulta em um ciclo de tempo de produção significativamente curto, no qual as empresas podem produzir e atender a altas demandas e prazos rigorosos sem comprometer a qualidade. A fundição sob pressão de hardware é muito mais eficiente na produção em larga escala em comparação com técnicas mais lentas, como a fundição em areia.

Consistência na produção em massa

A uniformidade é importante nos setores em que peças intercambiáveis são importantes. Como componentes do mesmo tamanho e propriedades são criados a cada ciclo de fundição sob pressão, o processo é usado para garantir a consistência em toda a produção em massa. O resultado de uma empresa que produziu cem peças e outra que produziu mil é o mesmo. Esse é um dos pontos fortes da fundição sob pressão que define esse nível de repetibilidade.

Hardware de fundição de alumínio

O alumínio é um dos materiais mais comumente usados durante o processo. A popularidade do Fundição sob pressão de alumínio O hardware se deve ao fato de o alumínio ser leve, livre de corrosão e ter ótimas características mecânicas.

O hardware fabricado em termos de hardware de fundição sob pressão de alumínio pode ser usado em setores como:

- Automotivo - Suportes, alojamentos e conectores.

- Eletrônicos - Dissipadores de calor, gabinetes e conectores.

- Construção - Acessórios de janelas e portas, maçanetas e fechaduras de portas.

Outra vantagem significativa do hardware de fundição sob pressão de alumínio é que ele tem a resistência de um objeto e, ao mesmo tempo, é leve, portanto, é particularmente útil no setor de transportes, onde a eficiência de combustível é crucial.

Por fim, é fácil fazer um revestimento, anodização ou pintura no hardware de fundição de alumínio para atender aos requisitos do projeto e oferecer aos fabricantes flexibilidade funcional e estética.

Hardware de fundição sob pressão de zinco

O zinco é outra matéria-prima importante no setor. Fundição sob pressão de zinco O hardware de zinco tem várias vantagens em comparação com o de alumínio. Embora o zinco seja mais pesado, ele também é mais forte e oferece grande resistência ao impacto e ao desgaste.

No produto que requer detalhes finos e bons acabamentos de superfície, por exemplo, acessórios decorativos, fechaduras, dobradiças e eletrônicos de consumo, o hardware de fundição de zinco é comumente usado. A fluidez superior de fundição do zinco permite que os fabricantes façam projetos complexos que não seriam feitos facilmente com outros metais.

A alta durabilidade das ferragens de zinco fundido é um de seus maiores pontos fortes em situações em que os componentes estão constantemente sob pressão mecânica. Isso é apropriado para ferragens de móveis, acessórios industriais e ferramentas.

Além disso, a fundição de zinco do hardware apresenta boa resistência à corrosão e pode ser revestida com vários acabamentos para garantir proteção e uma bela aparência.

Peças de hardware de fundição sob pressão

Quando nos referimos a peças de hardware fundidas sob pressão, estamos nos referindo aos inúmeros produtos produzidos por esse processo. Esses produtos incluem:

- Ferragens para portas e janelas - Maçanetas, dobradiças e fechaduras.

- Componentes automotivos - Componentes de montagem, gabinetes e suportes.

- Ferragens para móveis - Maçanetas e acessórios decorativos e suportes.

- Componentes eletrônicos - Conectores, dissipadores de calor e gabinetes.

As peças de hardware de fundição sob pressão são versáteis e, por isso, são muito importantes na maioria dos setores. Além disso, esses componentes são importantes para os fabricantes, pois são funcionais, precisos e econômicos.

Além disso, as peças de hardware de fundição sob pressão podem ser adaptadas para atender às necessidades especiais de aplicações individuais. Esses componentes podem ser desenvolvidos para proporcionar excelente desempenho, independentemente de se tratar de resistência, design leve ou apelo visual.

Por fim, há uma demanda crescente no mercado mundial por componentes de hardware de fundição sob pressão devido à necessidade de estabelecer uma produção eficiente e escalonável de produtos para satisfazer os consumidores.

Perfis aplicados nos setores

Setor automotivo

O setor automobilístico é um grande cliente da fundição sob pressão de produtos duros, pois os carros usam vários componentes leves e resistentes. A fundição sob pressão proporciona precisão e economia de custos em carcaças de motores e acessórios internos, entre outros.

Indústria de eletrônicos

Tanto as ferragens fundidas em latão quanto as ferragens fundidas em zinco são essenciais na eletrônica, especialmente na fabricação de carcaças, conectores e peças de resfriamento.

Construção e móveis

Fundição sob pressão As peças de hardware são normalmente usadas como maçanetas, fechaduras, dobradiças e elementos decorativos na construção e na produção de móveis.

Equipamentos aeroespaciais e industriais

Componentes leves e resistentes são apreciados no setor aeroespacial, enquanto o setor de maquinário industrial está aproveitando os benefícios de componentes de hardware confiáveis fabricados com a tecnologia de fundição sob pressão.

Materiais de fundição sob pressão para hardware

Alumínio

O alumínio é um material relativamente popular que geralmente é usado para produzir o chamado hardware de alumínio fundido. O alumínio é leve, não corrosivo e resistente, sendo adequado para os setores automotivo, aeroespacial ou eletrônico. Ele se mostraria benéfico, especialmente quando a minimização do peso é uma preocupação, como no caso do transporte, em que a economia de combustível é um fator. O alumínio pode suportar altas temperaturas de operação, e é por isso que ele é o preferido para ser usado em peças de motor e também em casos eletrônicos.

Zinco

O zinco é outra solução popular que é muito resistente e pode capturar detalhes muito finos. O hardware de fundição sob pressão de zinco é comumente usado quando o produto é um acessório decorativo, uma fechadura ou uma dobradiça e a capacidade de ser forte e preciso é necessária. O zinco tem uma força natural de resistência ao impacto e ao desgaste e, por isso, é uma boa opção para uso em aplicações em que as peças de hardware são usadas com frequência ou estão sob estresse mecânico. Ele também oferece um acabamento de superfície liso, que pode ser facilmente revestido, o que o torna muito durável e atraente.

Magnésio

Outra opção de fundição sob pressão é o magnésio, que, em ferragens em geral, não é tão comumente usado como o alumínio e o zinco. Ele é muito leve, mas muito potente, por isso é útil nos setores aeroespacial e eletrônico. Embora o magnésio nem sempre seja o material inicial a ser considerado na fundição de peças de hardware, ele está sendo considerado em cenários em que a redução de peso é fundamental, mas não há redução no desempenho.

Ligas de cobre e latão

Em alguns hardwares específicos, são utilizadas ligas de cobre e latão. Elas não são tão difundidas quanto o alumínio ou o zinco, mas os metais são ótimos para resistência ao desgaste e possuem boa condutividade elétrica. Isso os torna aplicáveis a elementos de hardware que exigem a integração de características mecânicas e elétricas, como alguns conectores ou terminais.

O futuro da fundição sob pressão de hardware

Com o desenvolvimento da tecnologia, a importância do "hardware die casting" provavelmente aumentará ainda mais. O processo está se tornando cada vez mais rápido e preciso devido à automação e ao projeto auxiliado por computador. Há um desenvolvimento de novas ligas para aumentar a força, reduzir o peso e melhorar a resistência à corrosão.

Esse setor também é afetado pelo aumento do foco na sustentabilidade. A fundição sob pressão é uma opção ecologicamente correta porque os metais recicláveis, como o alumínio e o zinco, podem ser reciclados. As empresas estão adotando estratégias de produção mais ecológicas para minimizar o uso de energia e o desperdício.

Os setores ainda dependerão da fundição sob pressão de hardware no futuro para fornecer as peças robustas, eficientes e precisas necessárias aos produtos modernos.

Conclusão

Para concluir, a importância da fundição sob pressão de hardware provou ser um dos processos mais vitais na produção contemporânea, oferecendo ao setor industrial a oportunidade de desenvolver componentes de hardware precisos, duráveis e econômicos. A fundição sob pressão é uma técnica que permite a criação de formas complexas com um alto nível de detalhes, acabamentos bonitos e alta qualidade, ao contrário de outros métodos convencionais. Isso a torna uma opção perfeita quando o setor em questão tem requisitos significativos de confiabilidade e precisão.

Os campos de uso desse processo são muito diversos. Desde a produção do fundição sob pressão de alumínio Desde as ferragens de zinco fundido, cuja resistência é bem conhecida e fornece os detalhes necessários para os produtos de consumo, o escopo dessa técnica é difícil de ser igualado. Além disso, a grande variedade de peças de hardware fundidas sob pressão garante que as empresas dos setores de construção, eletrônicos, móveis e outros possam encontrar os componentes que atendam às suas necessidades.

O aspecto mais interessante da chamada fundição sob pressão de hardware é que ela permite a produção em massa com conservação da produção em massa e, ao mesmo tempo, a qualidade e a resistência da superfície são excepcionalmente boas. Com o desenvolvimento da tecnologia e do setor exigindo a oferta de soluções de hardware de alto desempenho, a fundição sob pressão só se fortalecerá e continuará sendo um dos pilares da indústria mundial.