The aluminum thermostat housing is extremely important for the effective working and the endurance of automobile and industrial engines. The necessity to keep the engine at an optimum temperature to avoid the risk of overheating, which can lead to serious engine damage, is necessitated by engine cooling systems. Consequently, the structure and materials employed to make up parts like the thermostat housing are vital to the entire efficiency of the cooling system. Aluminum has evolved to be a popular material because of its light weight, strength, and excellent heat dissipation qualities; therefore, aluminum is a popular choice of material when demanded under the circumstance known as an aluminum thermostat housing.

Aluminum thermostat housing has gained increased popularity in a number of trade verticals as many industries demand high-performance and cost-effective parts. Motorcycles, heavy machinery, and marine engine aluminum thermostat housings also enjoy the value of resistance to high temperatures and other elements that the material has demonstrated in its application in automotive engines as well.

The concept of the significant aluminum thermostat housing, its use, advantages, fabrication, and application in the engine cooling system will be discussed in this article. We shall also explore the option of custom thermostat housing and how thermostat housing manufacturing is a crucial element when it comes to manufacturing high-quality and long-lasting components.

Índice

AlternarWhat is an Aluminum Thermostat Housing?

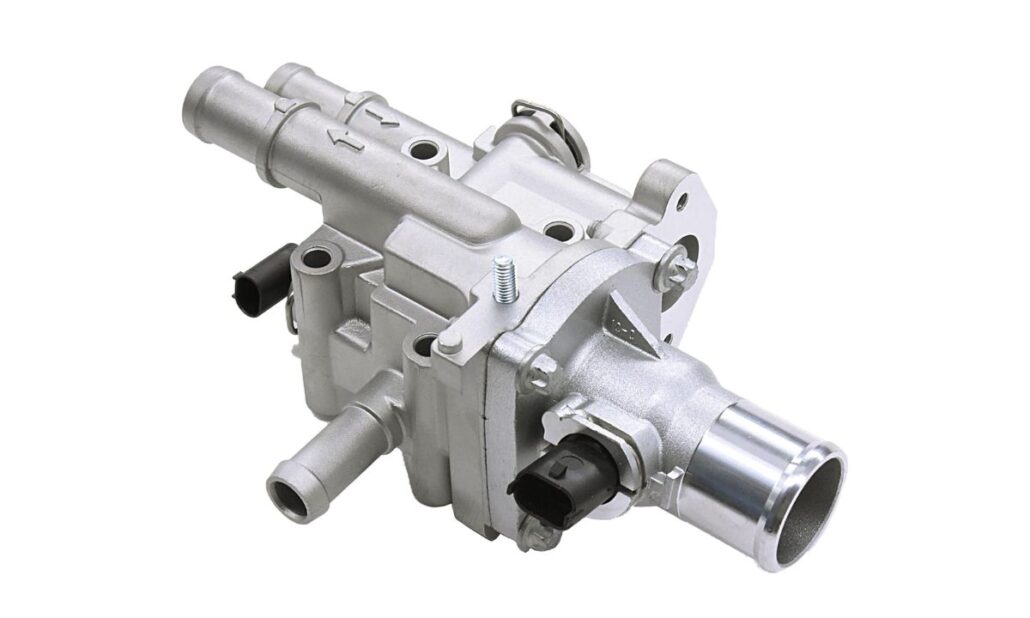

A thermostat housing, most often made of aluminum, is a very important part of the cooling system of an internal combustion engine, especially an automotive engine. Its major role is to accommodate the thermostat, which regulates the flow of coolant in the engine and the radiator. The thermostat controls the temperature of the engine, shutting down and opening up depending on the temperature of the coolant, and the temperature of the engine is at optimum.

Housing usually is composed of aluminum due to its lightweight attributes, ability to resist corrosion and thermal conductivity. It is made to be able to resist high-pressure coolant systems and rough operating environments, and cause no degradation after several years. Not only is an aluminum thermostat housing light in weight, but it is also highly temperature resistant, which is critical to ensuring proper engine cooling system.

Why should thermostat housing be made of aluminum?

The selection of aluminum in the production of thermostat housing has tremendously been in favour, as it comes with numerous benefits, namely:

a. Light and Strong

The lightweight nature of aluminum has seen this material being extensively used in automotive parts that require reduced weight without compromising the strength and performance of the parts. The lower weight will lead to more fuel efficiency, which is important among current vehicles.

b. Corrosion Resistance

Aluminum is naturally unaffected by corrosion, which is quite essential in automotive engines where there is always exposure to coolants, water, and chemicals. The presence of corrosion resistance makes the housing of the aluminum thermostat structurally stable and gives it the capacity to endure with reliable performance during its lifetime.

c. Dissipation of Heat

Aluminum has been a great heat conductor. It allows cooling of the engine away, making the thermostat have an optimum temperature. This conductivity of thermal energy assists in adjusting the engine temperatures and avoids overheating, which will lead to the destruction of engine parts.

d. Cost-Effective

Aluminum is a cheap metal when compared to other metals, hence it is a cost-effective alternative when mass production is involved. Furthermore, it can be lightly machined and cast, enabling affordable production procedures; therefore, it has reduced the production cost of offering a solution of a custom thermostat housing.

The Aluminum Thermostat Housing Materials

Aluminum thermostat housing materials are important in performance, durability and resistance to harsh engine operating conditions. Synthetic alloys that are common are:

1. Aluminum 356 Alloy

Aluminum 356 is famously known to be an incomparable castable, sturdy, corrosion-resistant metal that makes it a favourite medium in thermostat housing due to its admirable qualities. It is durably performing in extreme hot climate conditions.

2. Aluminum 6061 Alloy

This alloy has a good strength-to-weight ratio and corrosion resistance, which are suitable traits to be used as a custom thermostat housing for PMFMI automotives or industries.

3. Aluminum 7075 Alloy

Aluminum 7075, a super-strong alloy that fits on high-performance components, is ideal as a custom housing for a thermostat in engines where stress and temperatures are extremely high.

4. Alloy 319 Aluminum

With superior casting properties, Aluminum 319 is used in aluminum thermostat housings on automobiles and industrial engines where long-term wear resistance must be achieved.

5. Alloy 5083 Aluminum

The aluminum 5083 has good corrosion resistance, which makes it highly useful in the marine industry and heavy machinery industries, where it has to deal with corrosive factors due to moisture and harsh conditions.

These materials guarantee that thermostat housing manufacturing will generate durable, light and efficient engine cooling parts.

Aluminum Thermostat Housing Types

Aluminum thermostat housing is also of various types, depending on the manufacturing process, design requirement and the nature of the engine application in question. The typical automotive and industrial materials are listed below:

1. Sand Casting Thermostat Enclosure

The creation of larger and more complex parts is usually done through a process known as aerospace sand casting, where an aluminum thermostat housing is determined. Here, a sand mold is cast over the pattern of the thermostat housing, and molten aluminum is poured into the mold so as to create the part. The technique is best suited for manufacturing elaborate patterns and low to medium volume of production.

2. Die Cast Thermostat Housing

In die casting, molten aluminum is repeatedly forcefully injected into a steel mold, forming an aluminum thermostat housing of usually accurate dimensions and smooth surface finishes. This process is most suited to large volume manufacturing and is normally employed in instances where specific, strict tolerances and uniformity must be met.

3. Thermostat Housing Permanent Mold Casting

Permeant mold casting employs the use of metal molds in thermostat housing production, and parts manufactured in this form have very high-quality mechanical properties and very low porosity. When custom thermostat housings need to be created, it is common to use this method, which provides the advantages of a good amount of strength and durability.

4. Investment Casting Thermostat Housing

Lost-wax casting or investment casting can be used to manufacture a very intricate aluminum thermostat housing of complex geometry. Here, a wax pattern is applied with a ceramic shell, and wax is then removed. Molten aluminum is then poured into the mold. The process would be best suited to making special pieces with complex features.

5. Thermostat Housing Centrifugal Casting

Centrifugal casting takes advantage of the rotational motion to shape parts to have the same thickness and small defects. It is occasionally applicable in the production of aluminum thermostat housing in industrial applications where quality and blemish-free parts matter so much.

Uses of Aluminum Thermostat Housing

The main industry of aluminum thermostat housing is the auto industry. It, however, has a wide application in other sectors where there is a need for engines to cool down. The main applications are as shown below:

a. Automotive Engines

The thermostat housing plays an important role in the engine cooling system of the automotive industry. The housing gives the thermostat a secure place to rest and be guarded, as well as preventing the free flow of coolant. Automotive thermostats should be made of aluminum because of its high-temperature tolerance, anti-corrosiveness, and good heat-dissipating capability.

b. Heavy Machinery

Construction equipment, agricultural machinery and industrial engines are also heavy equipment that uses aluminum thermostat housing in order to achieve ideal operating temperatures. The shelter should be able to face harsh work injuries, so it should be able to endure the high amounts of vibration, temperature changes, and be covered by dirt and debris.

c. Motorcycles

Other small engines, especially those that use motorcycle have been accustomed to the use of the so-called aluminum thermostat housing due to its lightweight capacity. Weight reduction during performance-intensive needs is the priority in such applications, whereby aluminum gives a perfect combination of strength and weight.

d. Marine Engines

The symmetrical position of marine engines in the flush of seawater subjected them to corrosion, and engine parts might be destroyed. Cooling the system, Aluminum is less vulnerable to corrosion, thus ideal to use as a marine thermostat housing because the cooling system will still be operational and efficient even in the harsh marine acidic environment.

Custom Thermostat Housing Solutions

Automotive manufacturers and engine designers, on most occasions, need to incorporate special facilities such as a custom thermostat housing under specific engine designs or applications. A model built to custom specification can be required due to a number of factors, such as the design of the engine itself, available space, or the cooling system being required.

a. Custom Thermostat Housing Design

Designing a custom thermostat housing starts with an appreciation of how the engine is cooled, where the thermostat is and its location. Expert engineers collaborate with manufacturers to design a housing that would exactly fit in the engine bay with regard to space. Some solutions, including those that are called to use a certain thermostat housing, may demand particular properties like mounting points, inlet connection, outlet connection, and channels where coolant flows to work efficiently.

b. Selection of materials and alloy Selection

When it comes to solutions like a custom thermostat housing, selecting an aluminum alloy is of great importance. The nature of the application will determine the type of alloy that is used because specifications (strength, corrosion resistance and heat dissipation) will be required. Popular alloy grades in thermostat housing manufacturing include 356, 319, and 6061 grades, among others; they each have a different balance of properties that may suit different requirements.

c. Machining & Casting operations

After designing the product is complete the process of manufacturing the housing of the custom thermostat is completed through many different manufacturing modes that are available. The custom thermostat housing is manufactured through fundição sob pressão, casting and machining processes. Casting is a favourite when it comes to mass production, whereas machining is widely preferred in precision parts which have high tolerance. High manufacturing methods would make sure that the custom housing fits the needs of the engine.

Process of Manufacturing Thermostat Housing

The thermostat housing manufacturing process plays a vital role in ensuring the production of quality components, which are long-lasting. It can generally go through the following steps:

a. Casting

One of the usual processes applied in the production of “aluminum thermostat housing” includes casting. During this, melted aluminum is cast into a form, which represents the finished form of the housing. There are two main techniques that are used, which include sand casting and die casting, especially die casting being the most common when it comes to high volume, since it is more efficient and accurate.

b. Machining

The “thermostat housing” should still be machined after the casting operation, however, to fit and finish. These are the operations of drilling, threading, and surface finishing. The tolerance fit and the mandatory precision machining will result in the housing being precisely fitted in the engine cooling system within the most acceptable tolerances.

c.Quality Control & Testing

Industry-standard strength, durability, and performance are rigorously tested against every piece of aluminum thermostat housing that is produced. Nondestructive inspection through X-ray, Ultrasonic, and pressure testing are applied in finding any internal flaws or weaknesses of the casting. Quality control brings about reliability in the performance of the product over its lifetime.

d. Finishing

The last stage of a process known as thermostat housing manufacturing is finishing. This includes coating or other surface treatment, which will upgrade protection against corrosion, make it look better or last longer. Typical finishes are anodizing, powder coating or painting.

Advantages of the Aluminum Thermostat Housing

The uses of the term aluminum thermostat housing in engine cooling systems have a few advantages:

a. Increased Engine Performance

Thermal conductivity is high in aluminum, which guarantees that the heat generated in the thermostat and other related engine parts is adequately dissipated. This will help to improve the optimal performance of the engine by ensuring that the engine is kept at the right operating temperature.

b. Improved Durability

Corrosion resistance of aluminum implies that the thermostat housing will remain in place and serviceable even after years of exposure to abusive conditions. This strength means that it has a less frequent maintenance requirement, which means lower lifetime costs.

c. Reduction of weight.

Aluminum has a low weight, which contributes to the weight of the engine, lowering the fuel consumption and enhancing its performance. This is especially of the essence in automotive and motorcycle applications, where weight savings are of the essence.

d. Cost-Effective Manufacturing

Aluminum is a cheap and simple material to work with because it is simple to cast and mold. This renders it cost-effective in terms of using it in a mass production process of thermostat housing manufacturing.

The Problems of Thermostat Housing Manufacturing

Though the advantages of the aluminum thermostat housing are obvious, the production process is associated with certain difficulties. These are to provide specific tolerances, production of homogeneous casting quality and avoiding casting defects like porous material or cracks. Nevertheless, the development of casting technology and quality control has reduced the problems to a minimum, and manufacturers may produce components of high quality and reliability.

Aluminum Thermostat Housing manufacturer in China

China has become a world leader in the production and manufacturing of aluminum thermostat housing. China has well established a strong industrial base with significant manufacturing capacity and cheap production processes, thus it can be the main provider of custom thermostat housing solutions in both custom automotive and industrial applications around the world.

The high rate of industrialization and development of technologies in the country has allowed the Chinese producers to manufacture thermostat housing products and sell them cheaply without compromising their quality. Through its most modern casting methodologies, such as die casting and sand casting, China factories are deployed to provide specifications of high-performance aluminum thermostat housings in diverse industries, which include automotive, heavy machinery, and marine markets.

In addition, China has a huge supply of resources, skilled manpower, and experience in aluminum alloy that make it an important competitor in manufacturing custom thermostat housing for various companies in the world. China is likely to be a thermostat housing manufacturing centre as the demand for high-quality and yet low-cost aluminum parts grows.

Conclusão

To sum up, the inseparability of performance and reliability in gentle cooling systems is confirmed by the key role of the component of the bicycle’s aluminum thermostat housing. Aluminum has many advantages, such as light mass, resistance to corrosion, and excellent heat dissipation. If it is an autoparts, heavy-equipment, or marine engine application, aluminum thermostat housing components will guarantee a functioning thermostat that will not overheat and destroy the engine.

The nature of aluminum thermostat housing can be said to have a bright future as the demand for thermostat housing solutions under the banner of custom thermostat housing continues to swell, together with the development of thermostat housing manufacturing processes. Aluminum thermostat housings will remain as the key players in the success of engine cooling systems through the provision of personalised designs, accuracy in the production process and reliability in their functioning capacities.

FAQs: Aluminum Thermostat Housing

1. What is an aluminum thermostat housing?

The thermostat is located in the cooling system of an engine by using an aluminum thermostat housing. The use of aluminum is due to its lightness, resistance to corrosion, and heat dispersion capability.

2. What is the point in using custom thermostat housings?

It provides a better fit and performance because they are custom thermostat housing by fits particular engine arrangements or occupies space.

3. Which materials are used to produce thermostat housings?

To manufacture the thermostat housings, aluminum alloys, such as aluminum 356, 6061 and 7075 alloys are widely used due to their strength, lightweight and corrosion resistance.

4. What is the process of making an aluminum thermostat housing?

Thermostat housing Aluminum is usually manufactured either by die-casting or sand casting, after which a subsequent machining process and quality testing process occur, to achieve its precision and strength.