Defeitos usuais de fabricação em fundição sob pressão de alta pressão: Causas, prevenção e soluções

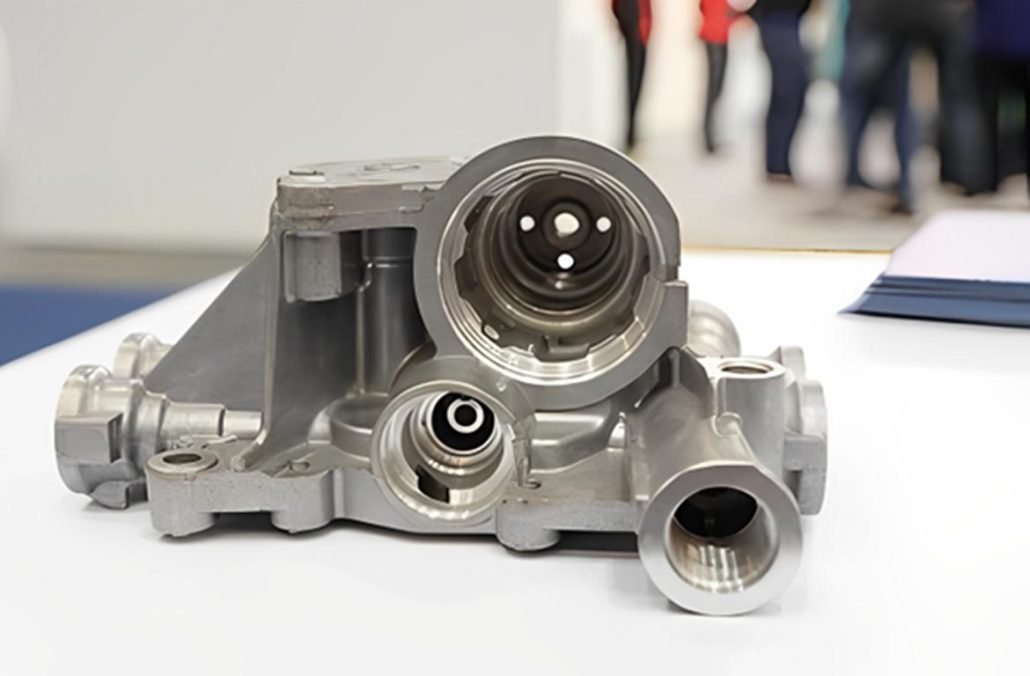

fundição de alumínio, fundição sob pressão, Fundição sob pressão de alta pressãoHigh-pressure die Casting (HPDC) is one of the most frequently utilized metal casting processes in current manufacturing. Manufacturers choose HPDC because it enables the production of complex metal parts that achieve both high precision and rapid production rates superior dimensional accuracy and smooth finishes. HPDC enables automotive and aerospace industries and the production of electronics components and consumer goods to manufacture lightweight durable parts for applications like engines and housings, structural elements, and mechanical assemblies. The manufacturing process of high-pressure die casting faces numerous risks that create substantial defects that decrease product quality while shortening the lifespan and compromising performance. Various defects form from improper mold design, turbulent molten metal flow, trapped gases, inconsistent cooling rates, and thermal stress during the production process. HPDC technology encounters seven primary defects which include porosity, cold shuts, shrinkage defects, flash formation, surface defects, misruns, die erosion, and soldering. These types of manufacturing defects cause deterioration of material strength while producing irregular dimensions and undesirable visual effects which can instigate component breakdown. Manufacturers combat production problems through the optimization of processing parameters and better-undermining methods along with controlled temperature systems and vacuum-assisted casting procedures. Real-time monitoring and simulation software are advanced quality control methods with further efficiency and reliability in the die-casting process. This article provides a comprehensive analysis of standard manufacturing issues during high-pressure die-casting technology with explanations of root causes and solution strategies to decrease these defects. It is only by understanding these challenges and applying best practices that manufacturers can improve the quality, longevity, and, of course, the performance of their die-cast components and simultaneously cut down on waste, and production costs. Proficiency in these manufacturing defects will assist die-casting engineers, production managers, and quality control specialists to optimize their processes for the best die-casting outcomes. 1. Porosity Porosity is defined by small holes or gas inclusions found within the metal matrix, and as a result, affects the mechanical properties, decreasing the strength, including allowing for air and gasses to pass through the structure, and leading to visible surface defects in die-casted products. Causes: Prevention & Solutions: 2. Cold Shut A cold shut is created when two streams of molten metal do not fuse properly and form weak bonding areas or visible seams in the casting. This defect not only decreases the mechanical strength but also increases the risk of a fracture, as well as negatively affects the component’s durability and appearance. Causes: Prevention & Solutions: 3. Shrinkage Defects Shrinkage defects occur due to shrinkage of metal during cooling which leads to internal voids or cavities, which deteriorate the structural integrity of casting. As a result, these defects reduce the mechanical strength of the final product, cause potential failure under stress, and cause poor surface quality, thus affecting both the functionality and aesthetics of the final products. Causes: Prevention & Solutions: 4. Flash Formation Excess thin metal layers formed at the parting line or die gap due to high-pressure metal escape are referred to as flash. Although flash can be trimmed off post-casting, over-flash leads to increased material waste, tool wear, and associated production costs and thus reduces the overall efficiency of the die-casting process. Causes: Prevention & Solutions: 5. Inspection of Surface Defects (Blisters, Crack and Wrinkles) A variety of surface defects, blisters, cracks, and wrinkles, degrade the visual appearance and mechanical strength of the casting and need to be prevented and eliminated. It causes weld defects that reduce the durability of the product, increase the rejection rate, and make the product stick poorly after post-casting treatments such as painting or coating. Causes: Prevention & Solutions: 6. Inclusions and Contamination Unwanted foreign particles, such as slag, oxide films, dirt, or other impurities, which are trapped in a final casting, create poor mechanical properties, weak structural integrity, and surface defects and are called inclusions. The presence of these contaminants can reduce die-cast component performance and durability so that they are not suitable for high-precision applications. Causes: Prevention & Solutions: 7. Misruns and Incomplete Fill A misrun occurs where there is a short filling of the mold cavity, which causes missing sections, thin walls, and weak points in the final component. Negative effects on the structural integrity and functionality of the part and in this way unsuitable for performance applications. Causes: Prevention & Solutions: 8. Die Erosion and Wear Molten erosion dies wear is the loss of the mold surfaces due to the high-speed metal continuously wearing the mold part surfaces until the required dimensions are achieved, which results in poor surface finish and short mold tool life. If this defect occurs, die replacement is common and consequently, production costs increase while casting quality varies. Causes: Prevention & Solutions: 9. Hot Cracking Cracks that occur during the semi-solid state of the metal, is due to high thermal stress and excessive shrinkage are known as hot cracking. These cracks degrade the mechanical integrity of the casting that is increase the chance of failure of the casting at the place where the cracks are present under stress or load. Causes: Prevention & Solutions: 10. Soldering The molten metal adheres to the die surface, which is difficult to remove with casting, causing surface defects, die wear as well as prolonged production downtime. Dimensional inaccuracies and poor surface finish are also caused by this defect, as it results in the overall compromised quality of the final product. Causes: Prevention & Solutions: Conclusion The high-pressure die casting is a powerful manufacturing process that creates complex metal parts at high accuracy at maximum efficiency. However, different kinds of defects arise using improper process parameters, material issues, and/or mold design flaws. Manufacturers can take preventive measures, e.g. optimal process control mold, properly selected material, etc., after understanding these usual manufacturing defects. A company can improve product quality, lower production costs, and achieve higher production efficiency in die-casting operations by emphasizing continuous process improvement as well as defect prevention strategies. Frequently Asked Questions (FAQs) 1. What are the major reasons for defects in high-pressure die casting? The main causes