Горячее камерное литье под давлением: Глубокое погружение в важнейший производственный процесс

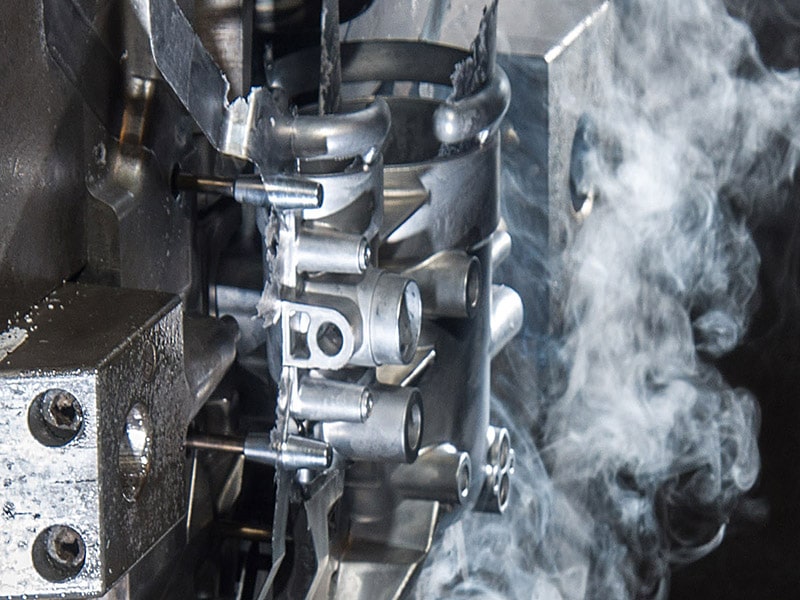

литьё под давлениемHot Chamber Die Casting is a very effective manufacturing process which is used very widely to produce metal parts to very high precision and an excellent finish on the surface. It is particularly suitable for casting metals with low melting points like zinc, magnesium and some alloys containing lead. It is typified by the fact that the injection system is immersed in molten metal, and so, high-speed cycle times and economy of mass manufacturing are possible. One similar place of comparison always pops up when the castings are considered regarding cold chamber die casting versus hot chamber. Although they are both variations of pressure die casting, they differ so much in terms of design, applications, and compatibility of materials used. An example is the hot chamber die casting, which is high-speed die casting where the furnace has been replaced with a machine. That comes with the limitation of the lower-melting-point metals. Conversely, the cold chamber type of machines is more aptly used with those liquids of a high melting point, such as aluminium and brass, since the hot metal does not come in direct contact with the equipment. Hot Chamber Die Casting process is characterised by minimal waste of material, low costs of labour, and complex shapes manufacture with high tolerances. It is popular in such industries as automotive, electronics, plumbing and consumer products. Nevertheless, the decision on whether to use cold chamber die casting or hot chamber is also dependent on the type of material used and the part design aspect. The article examines the important details of Hot Chamber Die Casting, its parts, materials, process description, constraints, and reasons as to why it is an essential process in the contemporary manufacturing industry. What is Hot Chamber Die Casting? Hot Chamber Die Casting is a metal casting technique where the molten metal is injected into a mould cavity at high pressure. The unique part of the given method is where the injection mechanism is placed: It goes directly to the molten metal. Cycle times and production efficiency are high with this setup, especially in metals of low melting point like zinc, magnesium and some lead alloys. Hot chamber. The name describes the system’s hot chamber as the injection mechanism (a plunger and gooseneck) is in constant contact (filled) with the molten metal area. As the plunger descends, it compresses the molten metal through the gooseneck and into the die cavity. As the metal sets, the mould opens, and the part is ejected, and this process is repeated innumerable times. Hot Chamber Die Casting Process Hot Chamber Die Casting Process is a process of high-precision and speed manufacturing technology utilised in the manufacture of metal parts, where the accuracy of the tool is very important, with great surface finishing. It is most appropriate in the alloys of low melting points; zinc, magnesium, and lead are examples of low melting point alloys. Its main characteristics are short cycle times and great material efficiency. The process is extensive in the manufacturing of a variety of products mainly found in the automotive, electronic, appliance, and hardware industry because of its capability to create complicated ends easily at an affordable per-piece price. The hot chamber die casting process is listed below in a stepwise manner: Hot Chamber Die Casting Process- Step by Step Overview 1. The Metal is melted It starts with the molten moulding of the metal (which is usually zinc or magnesium), in an incorporated furnace of the die casting machine. The molten metal is kept at a constant temperature within the metal pot that is directly connected to the casting machine. This unending heat provision ensures that the casting processes are continuous. 2. The process of filling the Injection System In hot chamber systems, there is a portion of the molten metal with a part of a component known as the gooseneck submerged. The plunger, which runs inside the cylinder of injection, is pulled backwards to a position where the molten metal may gush down to the gooseneck into the inlet hole of injection. The next step will involve injecting this metal into the die cavity. 3. Molten Metal injection When the gooseneck is filled, the plunger is either pushed forward by hydraulic or pneumatic pressure, which forces the molten metal through the gooseneck channel into the mould cavity (also called the die). This is done at a high rate and pressure to make sure that the cavity is totally filled before the metal begins to harden. 4. Casting and solidifying in the mould This hot metal in the die is quickly cooled down by the comparatively cold steel of the mould. Solidification takes several seconds, based on the size and complexity of the part. In this step, die cooling channels assist in the removal of heat to ensure that the cycle speed is not reduced and defects such as shrinkage or porosity are avoided. 5. Ejecting and opening of the mould Once the metal has been solidified, the die halves are opened. The ejector system is placed on the movable half of the mould, and it operates under force via the use of ejector pins and forces the completed casting out of the cavity. It is ensured that the part can come out without being damaged during ejection. 6. Secondary operation and Trimming After it is ejected, the piece might contain an extra material called flash, runners or sprues. These are either hand-trimmed or auto-trimmed. The part can be processed further depending on the application, like surface finishing, machining or coating. 7. Repeat Cycle The machine clears and cleans up to be used again. Hot chamber die casting is characterised by having such a quick cycle time, sometimes creating a few finished parts in just 10 to 20seconds according to the complexity and size of the part. Cycle Time and Efficiency The speed is the greatest advantage of the process of hot chamber process. Hot chamber machines. Unlike cold chamber die casting, where the metal has to be ladled