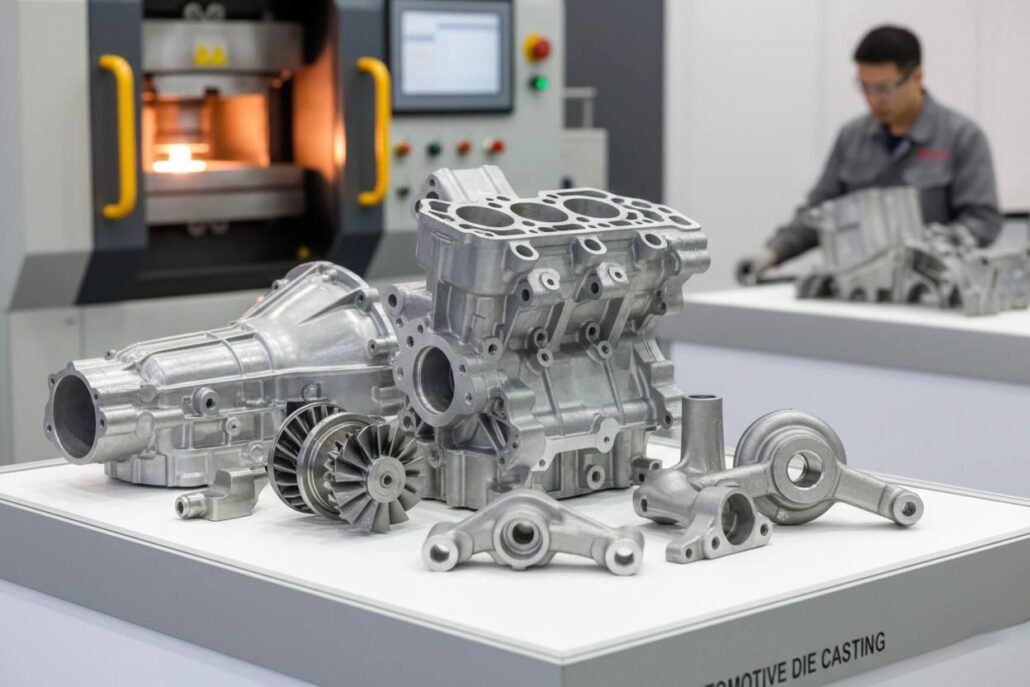

High-pressure die castings have ever-increasing use in automotive manufacturing processes and technology. With the increasing amount of electronics and passenger cars and trucks, there is a much greater need for mechanical type systems that can dissipate heat, add structural integrity, and other factors that make high-pressure die castings a very popular product and components for the automotive sector. This guide explores the secrets of the trade, explaining why automotive die casting is a major leap over traditional methods.

Оглавление

ToggleЧто такое автомобильное литье под давлением?

In its simplest terms, automotive die casting is a manufacturing process where molten metal is introduced into a die to create a part that solidifies in a fraction of a second. As the process unfolds, the metal comes in, the part is formed, and then it is processed down the line. It is high-speed, high-precision, and incredibly efficient for mass production.

There are two main types of this process:

Pressure Die Casting (PDC): Where molten metal is injected under high pressure into a steel mold. According to the North American Die Casting Association (NADCA), this remains the fastest way to produce complex non-ferrous metal parts.

Гравитационное литье под давлением: Where molten metal flows into the mold due to gravity. This is often used for parts where the mechanical properties of a slower solidification are preferred.

The 2026 “Giga” Revolution

The industry has moved far beyond small brackets. Today, we pinpoint whether high-pressure die casting is the right process to combine parts into a single die cast part to save the customer money. We are fighting for the whole industry so that more and more parts come into high pressure die casting. This is especially true for the complete rear underbody or front underbody, which are now being cast in one single shot on machines reaching up to 9,000 tons of locking force. This “megacasting” trend is significantly reducing the carbon footprint of vehicle assembly, as noted by Automotive News.

Choosing the Right Alloy for Automobile Die Castings

When a new customer comes to us, we look at tolerances, part size, and various features to pinpoint the right alloy. Here at The Die Casting, we have the ability to cast all three main alloy types, ensuring that we match the material to the specific application:

- Алюминий: This is sort of the go-to. It provides the best overall value of properties and economics. It has excellent thermal conductivity properties to get the heat out of electronics.

- Магний: If it’s something that is going to be in a very weight-sensitive application and you need very, very light weight, we suggest magnesium. It offers an incredible strength-to-weight ratio and is excellent for headlamp ballasts.

- Цинк: A heavy alloy, about two and a half times heavier than aluminum. However, you can do thinner walls and less draft, and the tool life is much, much better in zinc.

Automotive Aluminum Die Casting in the Era of Electric Cars

The future of the car industry will be pure battery electric vehicles. In this new era, automotive литьё алюминия под давлением is essential because the powertrain looks completely different. In the vast majority of electric vehicles, there is only one gear, so the gearbox is much smaller and less complicated.

However, we have some new parts that come with e-mobility. The inverter on top contains a lot of electronic components and needs to be completely pressure tight. We cannot accept any leakage; while oil leakage in an internal combustion engine is not nice, water leakage can kill the motor of an electric car once it’s filled with water. Therefore, automotive aluminum die casting must meet the highest standards of structural integrity.

Producing Complex Automotive Die Casting Parts

Automotive die casting parts run from “head to tail” in a modern vehicle. Because everything you do to reduce weight helps fuel economy and reduces emissions, these components are vital.

Power Electronics and EV Housing

Electric vehicle electronics generate heat, and you want to get that heat out. We use automotive aluminum die casting for:

- TCM Modules: Transmission control modules for shift-by-wire systems.

- EV Enclosures: Large housings that need to be a leak-free product to prevent water intrusion.

- EMI/RFI Shielding: Die castings inherently protect electronics from interference compared to plastics.

Structural and Mechanical Die Casting Automotive Parts

- Shock Towers: High-pressure castings that replace sheet metal assembly and welding, increasing rigidity.

- Motor Housings: Which stay a big portion of the die casting business as we switch to electric mobility.

- Battery Boxes: Large parts that are now being cast as a single piece to ensure they stay watertight.

Investment Casting and Automobile Die Castings

When die casting automotive parts require very high dimensional accuracy or represent a small and intricate design, we may look at Investment Casting, also known as the Lost Wax Method.

The Manufacturing Process Steps:

- Pattern Making: The pattern is made from wax, and the shape is exactly the same as the final product.

- Pattern Assembly: Wax patterns are assembled on a central runner, often referred to as a “tree.”

- Ceramic Coating: The assembly is dipped into ceramic slurry; repeated coating builds shell thickness.

- Drying and Dewaxing: The ceramic shell is dried, and the wax is melted and drained out.

- Pouring: Molten metal is poured into the ceramic mold. Once solidified, the ceramic shell is broken to reveal the part.

Centrifugal Casting: Principle and Purpose

To produce axisymmetric components such as pipes, tubes, and hollow cylindrical parts, we utilize centrifugal casting. In this process, the mold is made of metal and is rotated at high speed.

Machine Construction & Working

The mold is mounted on rollers and rotation is provided by a motor. When molten metal is poured into the rotating mold, the centrifugal force pushes the metal outward. The metal spreads uniformly, ensuring that impurities and lighter particles move toward the inner surface. This creates a central hollow cavity without using a core, resulting in a dense, strong outer surface with a uniform grain structure.

Manufacturing Excellence: Cold Chamber vs. Hot Chamber

In automotive die casting, the way metal is introduced into the die is critical to the quality of the final part.

Горячее камерное литье под давлением

Used for zinc and magnesium, the injection systems are actually physically inside the molten metal. A plunger comes down, extracts a given amount of material, and pushes it into the die. It’s a very fast process, sometimes it looks like popcorn coming out because it cycles so quickly.

Холодное камерное литье под давлением

Typically for aluminum, the metal is in a separate furnace. A ladle picks up a predetermined amount of liquid and puts it into the shot sleeve. This prevents the molten aluminum from attacking the plunger mechanisms.

Value-Added Processes: Beyond the Casting

At thediecasting.com, we love doing engineering and technical experience work. We look at the overall application to see if we can combine parts into a single die cast part to reduce costs.

- In-house CNC Machining: We have the ability to handle a very wide range of machining, from simple drill/tap stations to complex 5-axis work.

- Leak Testing: For parts that need to be leak-free, we set up pressure decay leak testing. We inject the part with air and measure the amount escaping to confirm we ship a leak-free part.

- Обработка поверхности: We apply various surface treatments and different finishes, from vibratory deburring to high-level corrosion protection.

Sourcing from Automotive Die Casting Manufacturers in China

For global manufacturers, sourcing from automotive die casting manufacturers in China provides a significant advantage. At thediecasting.com, we take pride in the fact that we help you get your “most bang for the buck” with a die casting. Our China-based facility allows us to be highly competitive on part price because we prioritize engineering efficiency.

Modern automobile die castings in China utilize AI-driven vacuum die casting. A vacuum is applied to remove air, which reduces porosity and improves strength and surface quality. This allows us to offer suggestions that might help save the customer money by doing features “as cast” rather than through secondary machining.

Further technical resources can be explored at diecastingschina.com и aludiecasting.com.

Quality Assurance and Sustainability

Sustainability is about possibilities balancing People, Planet, and Profit.

- Planet: We need to think about the environment. Die castings are 100% recyclable, offering a green solution for the 2026 market.

- People: Improving vehicles helps build a better society with safer, more efficient transport.

- Profit: Reducing assembly complexity through integrated die casting leads to direct savings.

We use custom gauging and x-ray of parts to ensure there are no micro-voids. If a part has tiny holes, we can perform resin impregnation, which helps fill any voids to meet the leak-free requirement. Our objective is to facilitate the design so the final product is both durable and cost-effective.

Why Partner with The Die Casting?

In this session, we discussed centrifugal casting, investment casting, and die casting. We love working with die castings and talking to customers about their new applications. If it’s not a good fit for a die casting, we will help you find the right process that fits your part.

At thediecasting.com, we provide the technical experience needed for the ever-increasing amount of electronics in the automotive world. Whether you need high-strength automotive aluminum die casting or an intricate structural automobile die casting, we will give you an honest opinion and help you get the part to an ideal solution.