Alumiini Die Casting yritykset Yhdysvalloissa

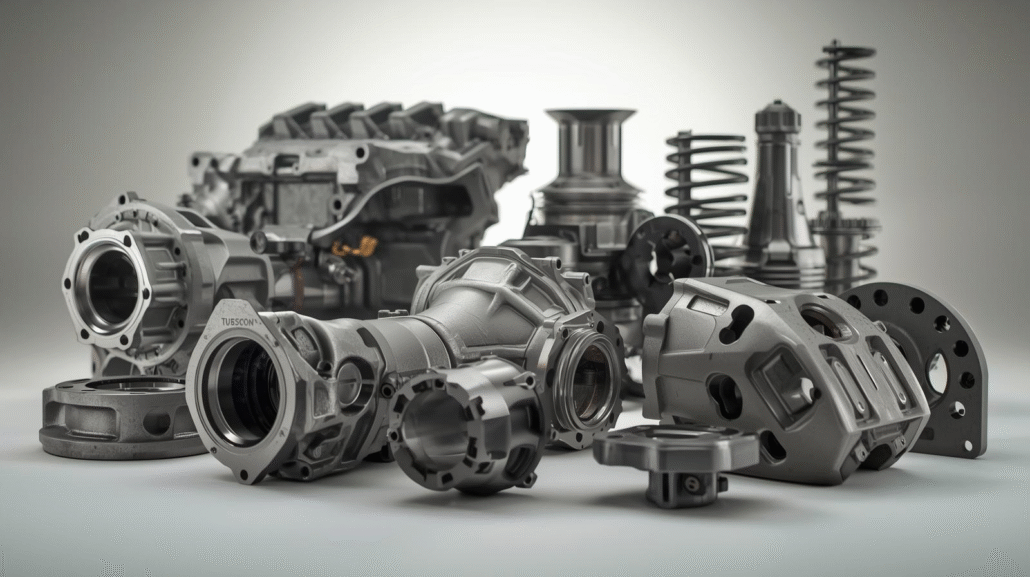

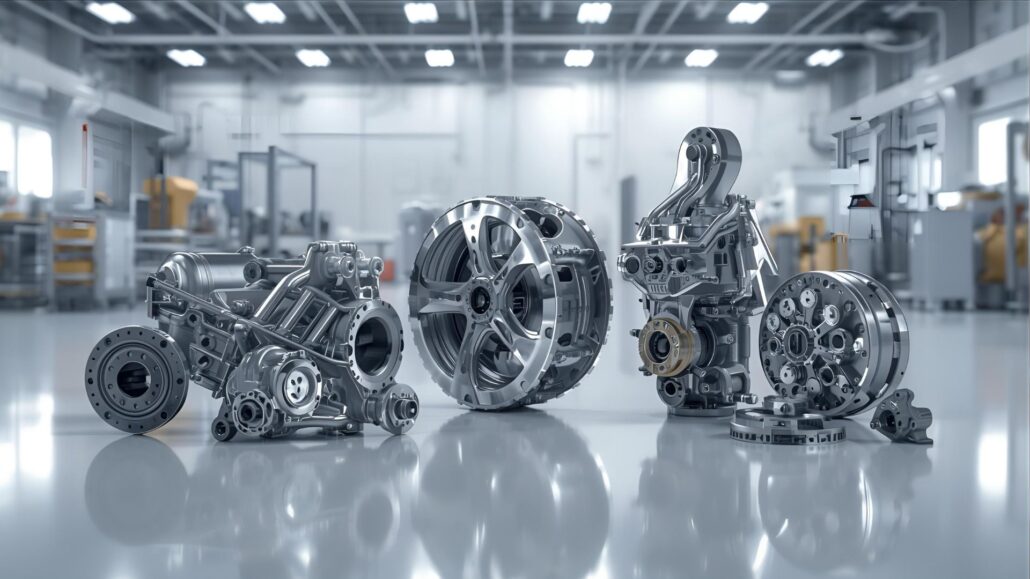

alumiinin painevalu, painevaluyritykset, painevaluyritysAlumiininen painevalu on nykyään yksi varmimmista ja taloudellisimmista tuotantomenetelmistä Yhdysvalloissa, erityisesti valmistajille, jotka vaativat kestävyyttä, pitkäikäisyyttä ja tarkkuutta. Tämä tapahtuu ruiskuttamalla sulaa alumiinia korkeapaineella teräsvaluun, ja näin saadaan aikaan osia, jotka ovat paitsi kevyitä myös mittatarkkoja ja kestäviä. Juuri tämä lujuus ja alhainen paino tekevät alumiinin painevalusta valintamateriaalin auto- ja ilmailuteollisuudessa, elektroniikassa, teollisuuskoneissa ja kulutustavaroissa. Yhdysvaltojen markkinoilla on joitakin maailman vakiintuneimpia alumiinin painevaluteollisuuden yrityksiä, jotka ovat niin suuria valmistajia, joilla on maailmanlaajuinen läsnäolo, kuin pieniä ja erikoistuneita yrityksiä, jotka ovat erikoistuneet räätälöityihin osiin ja kapeisiin sovelluksiin. Nämä yritykset ovat erittäin tärkeitä keskeisen teollisuudenalan ylläpidon kannalta, sillä ne toimittavat sellaisia teollisuuden segmenttejä kuin moottorilohkoja, vaihteistokoteloita, elektroniikkakoteloita ja rakenneosia. Yhdysvaltalaiset valmistajat ovat ansainneet maailmalla maineensa luotettavuudesta ja innovatiivisista tuotteista korkealaatuisella teknologiallaan, sertifioinnillaan ja keskittymällä laatutuotteisiin. Viime vuosien suuntaus on ollut painevalettujen alumiiniosien kysynnän valtava kasvu, koska ajoneuvojen keventäminen, sähköajoneuvojen tuotanto ja pyrkimys energiatehokkaaseen valmistukseen ovat viime aikoina kehittyneet. Amerikkalaiset yritykset ovat ottaneet käyttöön automaation, kestävät valukappaleet ja ylivoimaiset seokset, jotta saavutetaan korkeat tulokset näiden vaatimusten täyttämiseksi. Tässä artikkelissa luetellaan joitakin Yhdysvaltojen parhaita alumiinin painevalun valmistajia ja niiden saavutuksia, potentiaalia ja panosta nykyajan teollisuudelle. Sillä ei ole väliä, hankitko osia laajamittaisen valmistusprosessin tai erittäin teknisen sovelluksen suorittamiseen, nämä valmistajat ovat alumiinin painevalun parhaan amerikkalaisen teknologian ruumiillistuma. Mitä on alumiinin painevalu? Alumiinin painevalu on tuotantotekniikka, jossa sulan alumiinin korkea paine pakotetaan teräsmuottiin, jota kutsutaan myös muotiksi. Kun metalli jäähtyy ja jähmettyy, muotti avataan ja valmis osa heitetään ulos. Tämän prosessin avulla valmistajat voivat luoda vahvoja, kevyitä ja erittäin yksityiskohtaisia komponentteja, joilla on korkea mittatarkkuus ja sileä pinta. Keskeinen etu on se, että alumiinin painevalulla voidaan valmistaa monimutkaisia muotoja, joiden tuottaminen muilla valmistusmenetelmillä olisi muuten haastavaa tai kallista. Sitä käytetään laajalti esimerkiksi moottorilohkojen, vaihteistokoteloiden, elektroniikkakoteloiden, jäähdytyslevyjen ja rakenneosien valmistuksessa. Alumiinin painevalulla on useita merkittäviä etuja: Tällaisten vahvuuksien ansiosta alumiinin painevalu on noussut paremmaksi vaihtoehdoksi teollisuudenaloilla, jotka tarvitsevat luotettavia ja tehokkaita korkealaatuisia komponentteja vastaamaan teknisiä ja taloudellisia tarpeitaan. Top USA:n alumiinin painevaluyritykset 1. Dynacast International Dynacast International on ollut maailmanlaajuisesti yksi tunnetuimmista yrityksistä tarkkuusvalun alalla. Yrityksellä on vuosikymmenten kokemus pienten, monimutkaisten komponenttien valmistuksesta alumiini-, sinkki- ja magnesiumseoksia käyttäen. Yritys on hyvä tuottamaan komponentteja, joissa on tiukat toleranssit ja joissa on monimutkaisia ominaisuuksia, joita tarvitaan autoteollisuudessa, kulutuselektroniikassa, televiestinnässä ja lääkinnällisissä laitteissa. Maailmanlaajuinen toiminta tarkoittaa myös sitä, että Dynacast pystyy palvelemaan pienyrityksiä ja monikansallisia yrityksiä joustavuudella, innovaatioilla ja laadulla, jotka eivät vaihtele eri projekteissa. 2. Pace Industries Pohjois-Amerikan suurimmaksi painevaluyritykseksi noussut Pace industries on luonut hyvän maineen tarjoamalla kokonaisvaltaisia ratkaisuja. Heidän palveluvalikoimaansa kuuluvat suunnittelu ja tekninen tuki, painevalut, koneistus, pintakäsittely ja loppukokoonpano; he ovat tarjonneet yhden luukun ratkaisun auto-, teollisuus- ja kuluttajateollisuuden asiakkaille. Yrityksen toiminnan laajuuden ansiosta se voi käsitellä suuria volyymihankkeita ja asiakaskohtaisia hankkeita. Pace noudattaa myös kulttuuria, jonka mukaan se panostaa nykyaikaiseen teknologiaan ja kestäviin käytäntöihin, jotta se voi pysyä kilpailukykyisenä nopeasti muuttuvassa teollisuudessa. 3. Ryobi Die Casting (USA), Inc. Ryobi on tunnettu tuotemerkki maailman painevalusegmentillä, ja sillä on merkittävä läsnäolo Yhdysvalloissa. Sen toiminta Yhdysvalloissa keskittyy keskisuuriin ja suuriin alumiinisiin painevalukomponentteihin, jotka on tarkoitettu pääasiassa autoteollisuudelle. Ryobi valmistaa moottorilohkoja, vaihteistokoteloita ja rakenneosia, joiden on oltava kestäviä ja tarkkoja. Yritys on hyödyntänyt huipputeknologiaa ja laadunhallintaa, minkä ansiosta siitä on tullut maailman suurimpien autonvalmistajien ensisijainen toimittaja. 4. Gibbs Die Casting Gibbs Die Casting, toinen Yhdysvaltain markkinoiden johtava toimija, sijaitsee Hendersonissa, Kentuckyssa. Yritys on erikoistunut autoteollisuuden alumiini- ja magnesiumvaluihin, erityisesti vaihteistokoteloihin ja voimansiirron osiin. Gibbs painottaa voimakkaasti innovointia, jossa käytetään automaatiota ja kehittyneitä valmistustekniikoita korkean tehokkuuden ja työn laadun varmistamiseksi. Yritys sisällyttää liiketoimintaansa myös kestävän kehityksen käsitteen vähentämällä hävikkiä ja edistämällä ympäristöystävällisiä liiketoimintatapoja. 5. Apex Aluminum Die Casting Co., inc. Apex Aluminum Die Casting sijaitsee Ohiossa, ja sitä käytetään auto-, elektroniikka- ja laiteteollisuudessa. Yritys on hyvämaineinen työskennellessään keskivolyymisten tuotantoerien kanssa, mikä tekee siitä täydellisen vaihtoehdon yritysten kanssa, jotka vaativat tasaista tuotantolaatua, mutta eivät vaadi suurempien maahantuojien valtavia valtuuksia. Apexin tiimi pitää huolen asiakastyytyväisyydestä, palvelun luotettavuudesta, suunnittelusta ja valmistuksen tarkkuudesta. Se on vakiinnuttanut asemansa useiden yhdysvaltalaisten yritysten luotettavana kumppanina, koska sillä on hyvä maine tuottaa johdonmukaisia tuloksia. 6. KenWalt Die Casting Company KenWalt Die Casting sijaitsee Kaliforniassa, ja sillä on yli vuosikymmenen kokemus painevalujen; alumiinin ja sinkin valmistuksesta. Yritys keskittyy myös mittatilaustöihin ja palvelee sekä teollisuuslaitteiden että kulutustavaroiden toimialoja. KenWalt erottuu yrityksenä, joka tekee tiivistä yhteistyötä asiakkaan kanssa työn aikana.