Les 10 premières entreprises de moulage sous pression en Chine et aux États-Unis

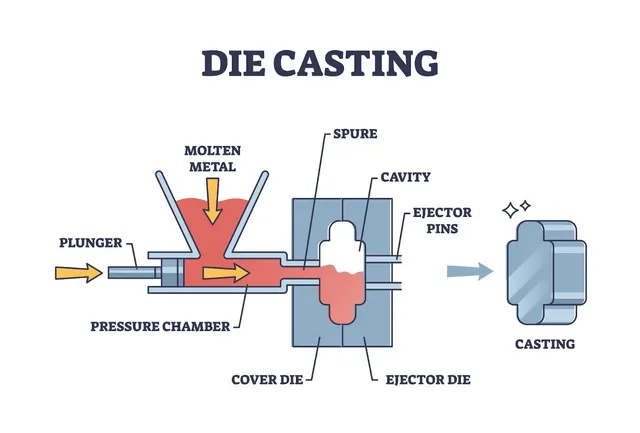

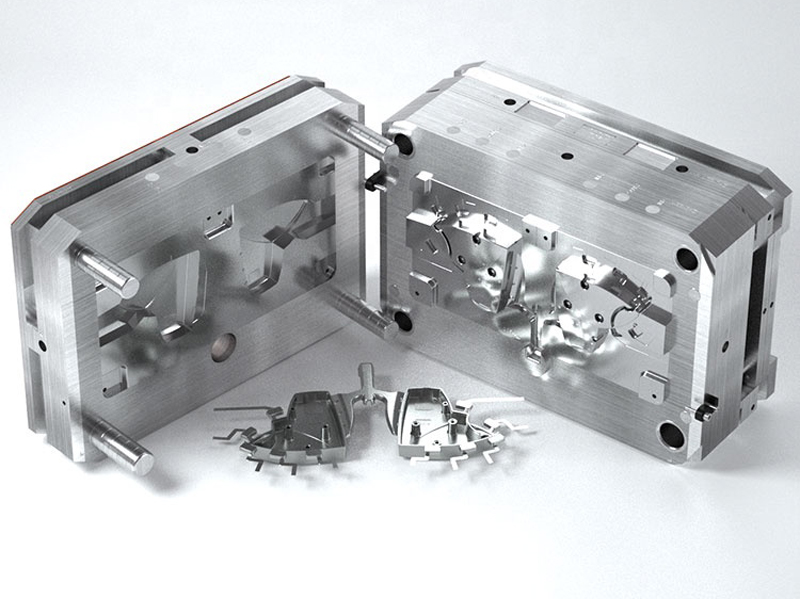

moulage sous pression, entreprises de moulage sous pression, société de moulage sous pressionLa méthode de production par moulage sous pression reste un processus fondamental pour la fabrication de divers produits dans de multiples industries, notamment la production automobile, les applications aérospatiales, les composants électroniques et la production de machines industrielles. Il s'agit d'injecter du métal en fusion dans une cavité de moule sous haute pression afin d'obtenir des composants métalliques durables et de haute précision. De nombreuses sociétés de services de moulage sous pression ont vu le jour en raison de la demande croissante du marché pour des solutions de fabrication de haute qualité. Les producteurs de pièces moulées sous pression les plus accomplis au monde opèrent en Chine et aux États-Unis, grâce aux progrès de leurs capacités technologiques et à leur volonté d'atteindre l'excellence en matière de fabrication. Le marché chinois fonctionne comme un centre mondial pour le moulage sous pression où les entreprises fournissent des services abordables avec des exigences industrielles strictes. Ces fabricants proposent des services complets comprenant la conception de moules, des services de production ainsi que des solutions de finition de surface et d'assemblage. Les États-Unis fonctionnent selon un système axé sur l'innovation, tout en maintenant des normes de qualité strictes et des pratiques d'ingénierie précises. Les entreprises de moulage sous pression américaines fournissent des solutions dans divers secteurs industriels qui offrent des qualités de performance exceptionnelles. Ce billet est une liste des 10 premières entreprises de moulage sous pression en Chine et aux États-Unis, avec un historique et des capacités, et sert de liste. Les entreprises mentionnées sont en tête de l'industrie parce qu'elles fournissent des services de production fiables à toutes les échelles, ainsi qu'une expertise spécialisée dans le moulage sous pression. 1. Sincere Tech Année de création : 2005Nombre d'employés : 100-200Type d'entreprise : Sincere Tech est l'un des plus grands fabricants chinois de moules d'injection plastique, de moulage sous pression, d'usinage et d'assemblage. Site web et contact Site web : https://plas.co/Phone : +86 135 30801277Email : steve@sincere-tech.comAddress : Rm101, N041, Donghu road, JingLian cun, qiaotou town, Donggguan City, Guangdong Province, China. 523000. Profil de l'entreprise Fournisseur chinois de moules d'injection plastique et de services de moulage, Sincere Tech est une entreprise chinoise de premier plan. Fondée en 2005, cette société a pour avantage concurrentiel sur le marché l'emboutissage du métal et du plastique, les moules d'injection plastique de précision, l'usinage CNC, le moulage sous pression et le moulage de silicone. Sincere Tech dispose d'un équipement de pointe, d'une protection NDA, de prix compétitifs et de 18 ans d'expérience dans la production de haute qualité. Avec des machines de moulage par injection de 60 à 1800 tonnes destinées aux secteurs de l'électronique, du médical, de l'automobile ou des cosmétiques, ses composants de moins d'un gramme à 8 kilogrammes sont produits efficacement. Leurs engagements en matière de qualité Sincere Tech se consacre à la création de produits qui répondent aux normes de qualité internationales ISO 9001:2015 et QS 9000:2015. Ils se sont consacrés à la qualité et cela a permis à l'entreprise de cultiver une demande massive, en l'exportant vers la Finlande et d'autres pays. Parmi tous les partenaires de l'industrie du moulage par injection de plastique qui fournissent presque la même qualité de services, c'est Sincere Tech qui se distingue comme un partenaire fiable et innovant pour le moulage par injection de plastique. Pourquoi choisir Sincere Tech ? Les clients qui recherchent des services de moulage sous pression en provenance de Chine ou des États-Unis devraient prendre contact avec ces entreprises de fabrication dignes de confiance qui leur fourniront une assistance professionnelle. 2. CNM Tech Co. Année de création : 20+Nombre d'employés : 100-200Type d'entreprise : CNM Tech Co. est une entreprise de fabrication de précision spécialisée dans le moulage sous pression, l'usinage CNC et les services d'assemblage. Site web et contact Site web : https://www.thediecasting.com/Contact : +86 13045898002Email : sales@thediecasting.comAddress : Adresse de l'usine : Rm 101, No.40, Donghu Road, Jinglian, Qiaotou town, Dongguan city, Guangdong Province, China. 523520. Profil de l'entreprise Thediecasting.com est le domaine officiel sous lequel opère CNM Tech Co., Ltd, un fabricant chinois exceptionnel de solutions de moulage sous pression. La société est une entreprise chinoise de moulage sous pression d'aluminium, de magnésium et de zinc, d'usinage CNC, de finition de surface et d'assemblage, dont le siège social se trouve à Dongguan, en Chine. CNM Tech a plus de 20 ans d'expérience dans les domaines de l'automobile, de l'aérospatiale, de l'électronique, etc. Son atelier d'outillage interne et ses machines CNC de pointe garantissent une fabrication de haute précision. CNM Tech propose tous les types de polissage, de sablage, de revêtement par poudre, de peinture à l'huile, etc. avec des produits de finition de haute qualité répondant aux besoins des utilisateurs du monde entier. Leurs engagements en matière de qualité CNM Tech Co., Ltd. dispose des documents ISO 9001:2008, TS16949 et ISO 14001:2015. Dans la plupart des cas, ces documents vous donneront l'assurance que la gestion de votre entreprise est de premier ordre et garantiront également la conformité avec les normes de l'industrie automobile et les activités respectueuses de l'environnement entreprises par l'entreprise concernée. Grâce au respect strict des réglementations en matière de qualité et d'environnement, CNM Tech fournit d'excellentes solutions de moulage sous pression avec un impact minimal sur l'environnement et jouit d'une excellente réputation sur le marché. Pourquoi choisir CNM Tech Co. Les clients qui recherchent des services de moulage sous pression en Chine ou aux États-Unis devraient prendre contact avec ces entreprises de fabrication dignes de confiance qui leur fourniront une assistance professionnelle. 3. GC Precision Mold Co, Ltd Année de création : 1999Nombre d'employés : 100-200Type d'entreprise : Notre société, GC Precision Mold Co., Ltd. réalise des moulages sous pression d'aluminium, de zinc et de magnésium, des usinages CNC et des moulages par injection de plastique. Site web et contact Site web : https://aludiecasting.com/Contact : +86 131 4886 5556Email : info@aludiecasting.comAddress : Adresse de l'usine 1 : No. 30 Huan Zhen Rd, Qi Shi Town, Dongguan City, Guangdong Province China, 523516 Profil de l'entreprise GC Precision Mold Co. Ltd, opérant sous Aludiecasting.com, est un site de fabrication de pièces moulées sous pression et d'usinage de précision qui est l'un des principaux fabricants chinois. L'entreprise a été fondée en 1999 et ses services comprennent le moulage sous pression de l'aluminium, du zinc et du magnésium, le moulage par injection de plastique, l'usinage CNC et la finition de surface. Elle dispose de machines de pointe telles que des machines de moulage sous pression (120 - 1600 tonnes) et des machines de moulage par injection (80 - 2800 tonnes) destinées à des industries telles que l'automobile, l'aérospatiale et l'électronique. L'entreprise applique des normes de qualité très strictes afin de fournir des solutions de fabrication exactes, durables et moins chères dans le monde entier. Leurs engagements en matière de qualité GC Precision Mold Co Ltd fournit les meilleures solutions de moulage sous pression et d'usinage, conformément à la certification ISO 9001. Leur contrôle de la qualité est si strict qu'ils testent la précision, les machines CMM, les rayons X et les spectromètres afin de garantir la fiabilité de leurs produits. Grâce au respect strict des normes internationales, l'entreprise garantit la livraison de composants cohérents et de haute qualité avec un minimum de réclamations de la part des clients en raison de l'aspect de la fiabilité pour les raisons indiquées dans chaque projet. Pourquoi choisir GC Precision Mold Co, Ltd ? Les clients qui recherchent des services de moulage sous pression en Chine ou aux États-Unis devraient prendre contact avec ces entreprises de fabrication dignes de confiance qui leur fourniront une assistance professionnelle. 4.