Die Casting Automotive Parts has been involved in automobile production for over one hundred years. With the course of time, the process has been advanced with better materials and technology. It is also now more prominent today in decreasing vehicle weight and enhancing fuel efficiency. The contemporary automobile sector relies on accuracy and power. The cars of the modern world have to be safe, reliable, and efficient. A method of doing this with a lot of trust is by casting an automotive part through die casting. This process is a combination of precision and high manufacturing. It provides automakers with strong, lightweight, and uniform parts.

The increased use of automotive die casting is not merely about performance. It is also cost savings, increased speed of production, and sustainability. Automakers are able to create thousands of the same parts and of the same quality. This is necessary in mass production.

In the present paper, we are going to discuss the significance of automotive casting. We are going to watch its work, its importance, and what tendencies of the future are influencing the industry. At the conclusion, you will know the reason why the contemporary manufacturing of vehicles is supported by automotive die casting.

Tartalomjegyzék

ToggleAutóipari öntvények

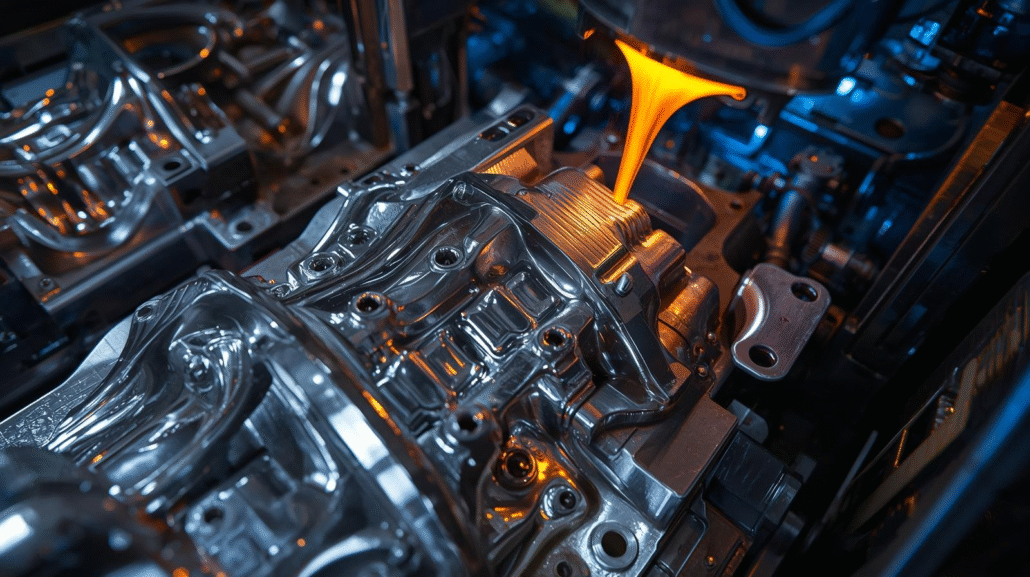

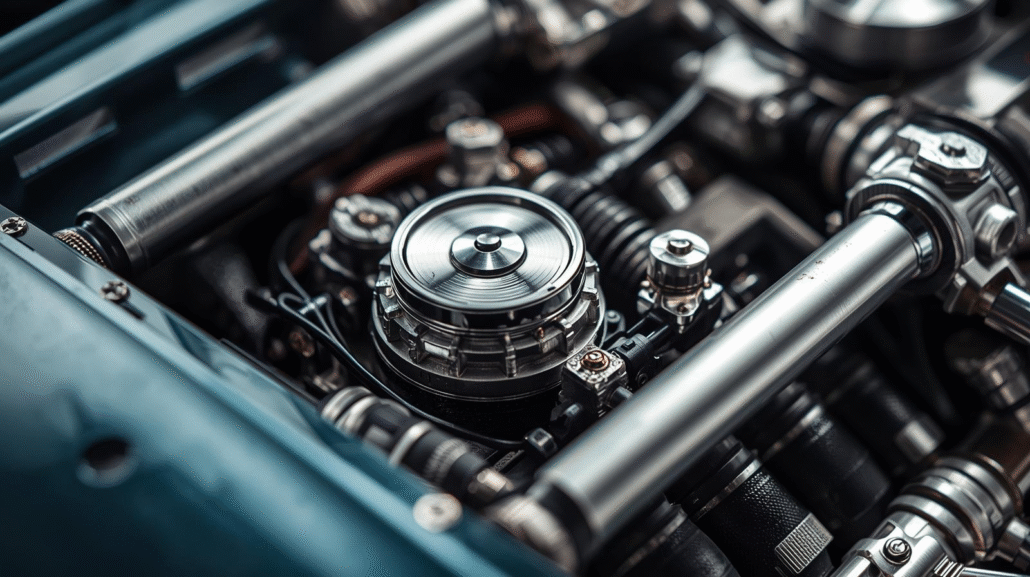

Car manufacturing is one of the most sophisticated technologies through which parts are manufactured by a process known as automotive die casting. It is contrasting to the traditional casting as it operates under high pressure. Molten metal is injected into a steel mold known as a die in this process. The die is extremely precise, and hence the section that is produced is of specific dimensions.

This is done by first melting the metal. The most common ones are aluminum and magnesium. After the liquid metal is melted, it is forced to fill the die at an extremely high rate. The die is filled with the metal that solidifies. Upon opening the die, the completed part is cut off.

Two systems of automotive die casting are in existence:

- Hot-chamber die casting – This process is applied to such metals as zinc and magnesium. The melting pot is connected to the machine, and then molten metal is simply pushed into the die. It is quicker, though it can work only with low-melting metals.

- Cold-chamber die casting – This is applied to aluminum, and occasionally to magnesium. Molten metal is then poured into a chamber and then pushed into the die. It is more time-consuming but effective with metals that have a higher melting point.

The principal advantages of automotive die casting are speed, accuracy, and strength. Thousands of parts could be made using one die. All sections are emerging virtually the same. It has smooth surfaces, and this means that it does not require additional machining.

When it comes to large-scale production, automotive die casting will do. It is used by car companies to manufacture engine blocks, gear houses, wheels, and even structural parts. It is economical in both time and cost, besides providing powerful yet lightweight components.

The die casting automotive parts Process

The die casting automotive parts making process follows a number of steps. Every step is significant so as to be accurate, strong, and reliable.

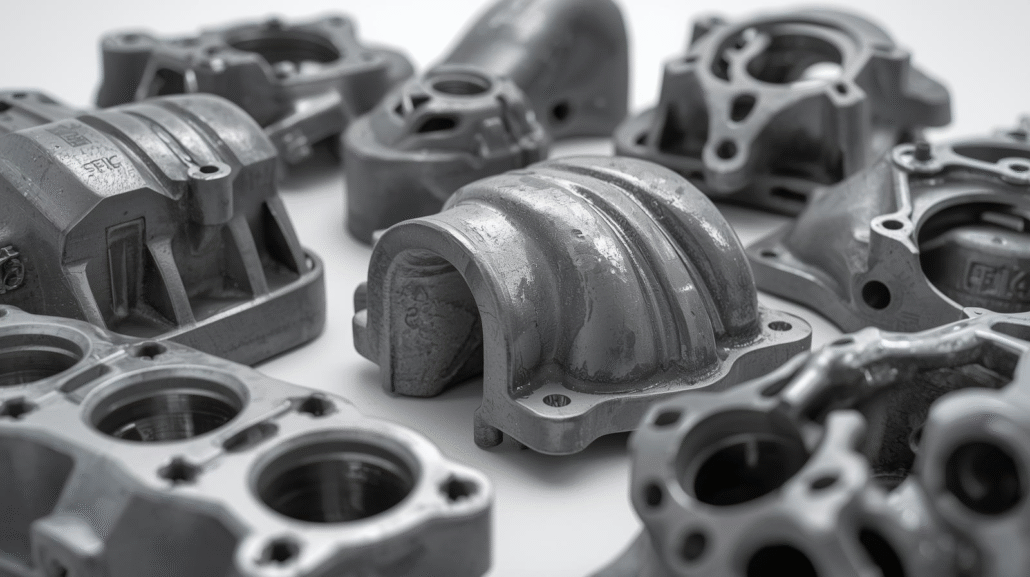

Preparing the Die

It starts with the design and fabrication of the die. A die is a form of hardened steel. It consists of two parts that join each other. The die is designed with the specifics of the part by engineers. The die should be powerful enough to endure pressure and heat.

Melting the Metal

The second step entails melting the metal that was selected. The most common are aluminum, magnesium, and zinc. The heated metal is taken through a furnace where it is melted into a liquid. The temperature should be under control to avoid impurities.

Injecting the Metal

After being molten, the metal is forced into the die at very high pressure. This is the most important process in die casting the automotive parts. High pressure is used to make sure that the liquid metal fills all the corners of the die. This imprints analytical lines, flattened areas, and exact forms.

Cooling and Solidifying

Once injected, the metal solidifies rapidly in the die. The metal is solidified through cooling and gives the part strength. Cooling time is determined by the size and thickness of the part.

Starting the Die and Ejection of the Part

When the metal is solidified, the die opens. The part is forced out of the mold by special ejector pins. The section is now in its overall shape, but it can still require finishing.

Trimming and Cleaning

Excessive metal that results is called flash, and can occur within the edges of the casting. This is trimmed away. It is followed by cleaning the part and heating it occasionally to achieve additional strength.

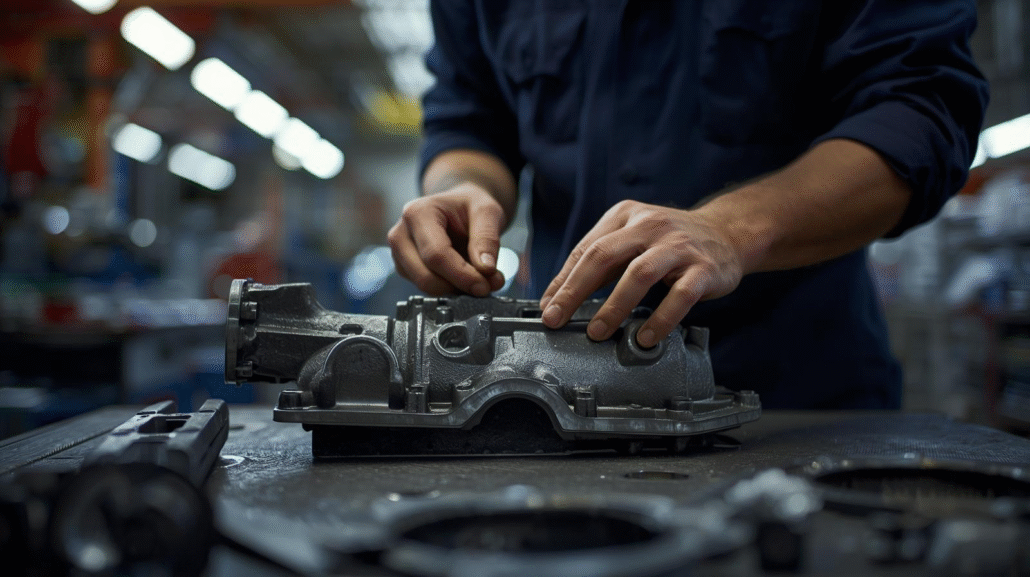

Finishing and Inspection

Surface finishing and inspection are the last. Certain portions can be painted, polished, or coated. Each section is thoroughly screened against flaws. Only the ones that are of quality are passed to be used.

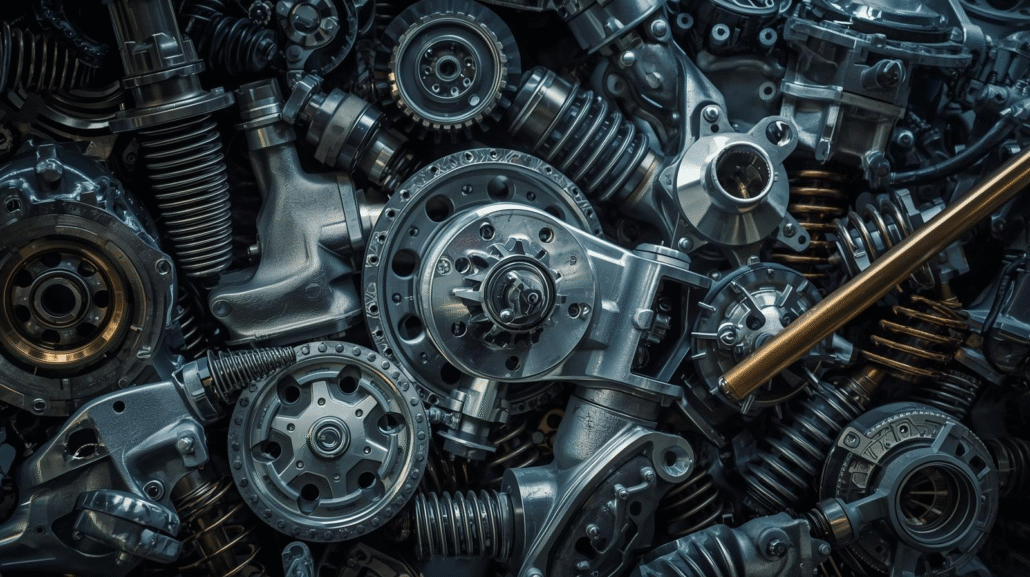

What happens to be a die-casting automotive part?

Die casting automotive parts- are those components made with molten metal that is pressed into a mold under pressure. This produces components whose shapes and dimensions are accurate. The molds, referred to as dies, are made with great accuracy to fit the part that is needed.

The most used metals are aluminum, magnesium, and zinc. These are lightweight and strong metals. Automakers like them due to the fact that they make the vehicle lighter without sacrificing durability.

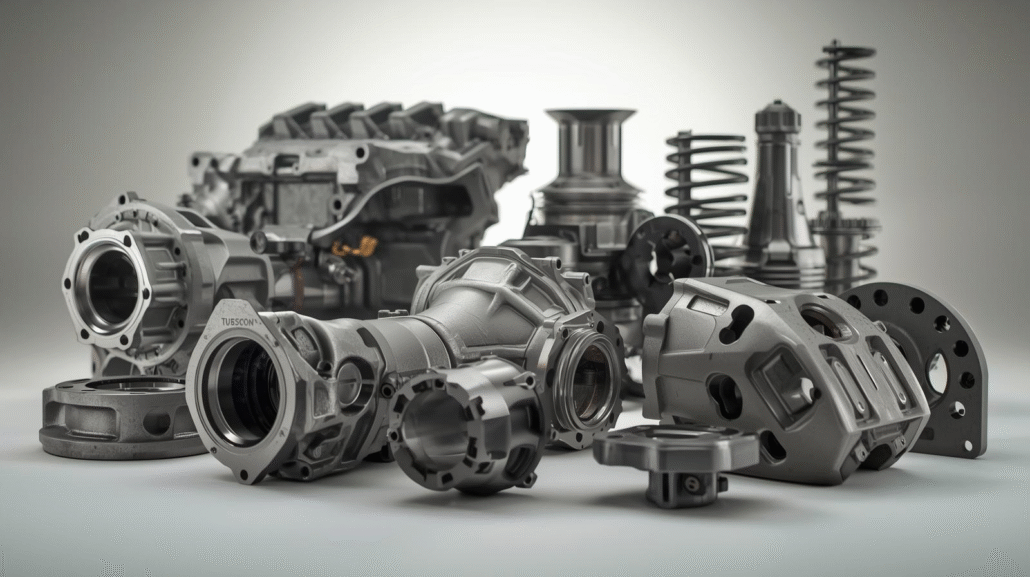

Typically used die-casting automotive parts are:

- Engine blocks

- Sebességváltó házak

- Wheels

- Structural brackets

- Electronic housings

This is because, through this process, automakers can manufacture cars that are of high quality in terms of safety and efficiency.

The Industry of Automotive Casting Role

One of the most traditional and consistent processes of car production is called automotive casting. It works molten metal into components of complicated forms. Engines, transmissions, suspensions, and many other systems require these parts. The contemporary automobile sector cannot operate without this procedure.

The primary purpose of the automotive casting is to make strong parts at a reduced cost. With casting, the car companies can make thousands of similar parts at a time. This is significant since automobiles need accuracy and stability. One fault may have an impact on the safety or performance.

Flexibility is another application of the automotive casting. The ability to design more complex shapes that otherwise were too costly to machine is possible for engineers. Through casting, thin walls, hollow, and delicate details can be created. This allows automakers to have more freedom with the development of new models.

Another important issue is the reduction of weight. Light cars are more efficient and generate fewer emissions. Aluminum and magnesium alloy automotive casting is used to decrease the total weight. This enhances fuel efficiency and promotes sustainability in the world.

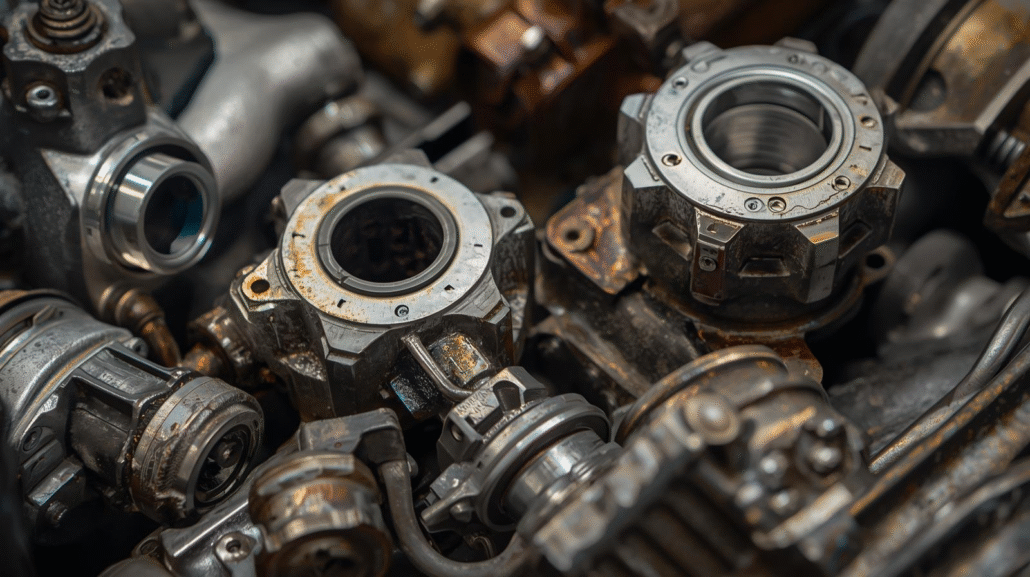

Durability also matters. Automotive casting produces components that can resist extreme temperatures, heavy loads,s and continuous vibration. To take an example, the timing of the breakdown of such items as cylinder heads and transmission housings is to be measured in several years.

Lastly, innovation is supported by the casting process of automotive parts. EVs make use of new castings, including battery enclosures and motor brackets. Casting has been changing according to the needs of the changing industry.

To put it succinctly, automotive casting does not only pertain to the production of components. It is concerning empowering safety, productivity, and advancement within the whole automotive sector.

Choices of Materials in the casting of automotive Parts

The material used in die casting automotive parts is of critical concern. The material influences strength, weight, cost, and performance. The various metals that are used are dependent on the application of the part in the vehicle.

Alumínium ötvözetek

Die-casting automotive parts are most often made of aluminum.

- It is lightweight but strong.

- It is anticrostalline, and that is significant in vehicles that last long.

- It is also very thermally conductive and is perfect for engine and transmission components.

- Engine blocks, cylinder heads, housing, and structural parts are commonly made of aluminum alloys..

Magnézium ötvözetek

Magnesium is even lighter than aluminum.

- It has a good strength-to-weight ratio.

- It is also good at absorbing vibration and can be used in steering and transmission components.

- It is applied to interior components, brackets, housings, and light body structures.

- It is light, reducing the total weight of the vehicle, which is useful in electric vehicles.

Cink ötvözetek

- Smoother and smaller die casting automotive components that are cast using zinc.

- It admits a great deal of fine details and thin walls.

- It is also good in wear resistance, thus enhancing durability.

- It is economical for the small production of large quantities of parts.

The general applications comprise locks, handles, gears, and decorative applications.

Copper Alloys (limited use)

Yet, copper and copper-based alloys have fewer applications in die casting automotive parts, although there are applications.

- They are superconductors of electricity.

- They are applied in connectors and electric housings.

- They are not used much since copper is heavy and costly compared to aluminum or magnesium.

Why These Materials Are Chosen

The auto industry demands powerful materials that are light and wear-resistant. These requirements are fulfilled by aluminum, magnesium, and zinc alloys. They render cars safer, lighter, and fuel-efficient. The automotive parts of the lightweight alloys in the die casting will be further demanded as the number of electric vehicles increases.

Merits of die cast automotive components

Die casting of automotive parts has numerous advantages that make it a requirement in the manufacture of cars. The reason automakers would select this approach is that it is both accurate, fast, and durable. We will take a closer look at the key benefits.

Precision and Accuracy

Precision is one of the largest benefits of die casting automotive parts. The molten metal is poured into all corners of the die. This results in components of precise dimensions and finishes. Accuracy implies that there is less machining required in the latter. It also makes sure that all the parts fit the vehicle assembly to perfection.

The use of high-strength and low-weight

The current cars should be powerful but have to be light as well. This balance is attained by die casting automotive parts. Alloys of aluminum and magnesium are lightweight and strong. With such materials, the overall weight of the car is reduced. This produces a higher level of fuel economy and performance without compromising safety.

Economy in Large-Scale Production

The die casting automotive parts are suitable for large-scale production. After making a die, it can be reused a thousand times. This decreases the unit price. The rate of production reduces the labor costs as well. This efficiency is paramount to the automakers in order to remain competitive.

Excellent Surface Finish

Die casted parts contain smooth surfaces and fineness. This saves the additional finishing labor. The part is often available in many cases, as it is out of the mold. The appearance of visible car parts is also enhanced by the good surface finish.

Consistency and Reliability

All cars require components that work similarly. Automotive parts are die casted to provide uniformity. Castings are almost the same as the previous one. This is a safety enhancement and minimizes the chance of defects.

Design Flexibility

The other significant benefit is design freedom. Thin-walled, curved, and complex parts can be made by die casting. This will enable the engineers to be creative and produce parts that can be achieved to fit in small designs.

Long-Term Durability

Automobile components are subjected to stress, heat, and vibration daily. Die casting automotive components are tough to support such environments. They are durable, meaning that vehicles would last longer and need fewer replacements.

Applications of automotive castings

Almost every component of a car is made by castings of automotive type. They can be located in engines, transmissions, chassis, and body structures.

Példák:

- Components of engines – cylinder heads, engine blocks, valve covers.

- Comments parts – housing, torque converters, clutch covers.

- Bracket parts – control arms, brackets, Suspension components.

- Electronic housings – Cases of sensors and control units.

The automotive castings are flexible, and this enables the automakers to be innovative. The company can develop complicated components at low costs.

Safety in castings for automotives

The most significant step of an automotive casting is quality control. Cars should be secure, dependable, and durable. This implies that each cast part should be of high standards. Any minor fault might lead to severe issues on the road.

Méretpontosság

Precise measurements are required in each part of automotive casting. When making a part that is too small or too big, it will not fit within the vehicle. Precision tools are applied by engineers who check the size and the shape of every casting. This ensures a harmonious working of all parts.

Surface Inspection and Visual Inspection

Casting may get to its problem areas early on. The part may be weakened by cracks, holes, or rough patches. These flaws are closely examined by the surface by the inspectors. In case of any defect, the part is rejected even before it enters the assembly line.

X-ray and Non-destructive Testing

There are also certain flaws concealed within the metal that are not visible. That is why the X-ray testing is frequently utilized in automotive casting. It is a technique that reveals emptiness, cracks, or air pores in the part. Non-destructive tests enable businesses to locate defects without the need to shatter the part into pieces.

Mechanical Strength Testing

Components produced by the auto casting have to withstand stress, heat, and vibration. Measuring strength, hardness, and flexibility is done on samples by engineers. These are tests that ensure that the parts can withstand the actual driving conditions.

Consistency Across Batches

Automobile manufacturers make large numbers of parts in a day. Quality control will be used to guarantee uniformity in all castings regardless of the time of the casting. Random sample parts are also tested out of each batch to ensure that they are of equal high standards.

The International Standards and Certifications are provided

Casting of autos is of international quality,l ike ISO and ASTM. These regulations establish the quality and safety guidelines. The attainment of these certifications creates confidence among automakers and customers.

Overall, inspection is not the only concern of quality control in automotive casting. It is concerned with a safe, reliable automobile. Tight tests and international standards ensure that cast parts can be relied upon in the streets.

The Future of the Automotive Die Casting

There is a rapid change in the automotive industry. The future is being determined by electric cars, green objectives, and high-tech production. Automotive die casting will continue to be even more important in this new era.

Greater and Blended Castings

The shift to larger and single-piece castings is one of the largest tendencies. Carmakers are no longer making numerous small parts and fixing them together, but are now making some of the large parts as one piece. The most recognized one is Giga Casting of Tesla. The firm has immense machines that cast whole rear or front parts of its cars in a single cast. This makes it less weighty, less expensive, and more rapid to manufacture. This is a trend that is being followed by other automakers.

Promotion of Electric Vehicles

To enhance the driving range, the electric vehicles (EVs) require lighter components. The battery is a bulky object, and weight reduction is a major issue in the frame and body. This is solved by means of automotive die casting in aluminum and magnesium. EVs already include cast battery housings, motor mounts, and cooling systems. Demand for die-cast parts will increase as EV usage increases.

Use of Recycled Metals

The auto industry is currently concerned with sustainability. Most companies are resorting to recycled aluminum in the form of die casting of automobiles. Recycling of aluminum is more economical and emits less than extracting new material. In the coming years, the casting plants will depend on a closed-loop recycling system, which encompasses the melting down of old car parts and using them in new cars.

Smart Factories and Automation

The contemporary casting facilities are getting more automated. Robots deal with melting, pouring, trimming, and inspection. There is also the usage of sensors and artificial intelligence (AI) to identify defects at an early stage in the process. There is a faster, safer, and reliable process of making automotive die casting in smart factories.

Stronger and Lighter Alloys

The metal alloys are on the edge of research. There are new combinations of magnesium and aluminum being experimented with to enhance strength and maintain low weight. Alloys resistant to heat are also relevant in components such as engine casings and battery cases of EVs. These advanced materials will be applied in the future in the manufacturing of vehicles that are even safer and efficient through the use of automotive die casting.

International Diversification of Die Casting Factories

Die casting plants are increasing as there is an increase in car demand across the globe. Asia, particularly China and India, is taking the lead in production. Europe and North America are also investing in high-tech casting facilities. The worldwide expansion means that the automotive die casting will continue being a focal process in the manufacture of vehicles all over.

Következtetés

Without the die casting automotive parts, the modern car industry would not exist. The process enables the car manufacturers to produce cars that are powerful, lightweight, and low-cost. It is precise and efficient, and thus the industry has the capability of producing millions of quality parts annually.

Some of the processes include automotive casting and automotive die casting, thus making sure that all cars are of high standards in terms of safety and performance. In almost every system of a car engine, transmission, electronic housing, and battery case, there are automotive castings.

The advantages are clear. Die casting of car parts saves money, time, and develops products that are durable. Their support of innovation also consists of permitting sophisticated design and lightweight solutions. These advantages will only be increased as cars become more sophisticated.

In the future, the automotive industry is bound to the future of automotive die casting. The next stage of manufacturing will be larger castings, sustainable materials, and intelligent factories. Die-cast parts will be relied upon in electric vehicles, especially for efficiency and performance.

Concisely, die casting automotive parts are not parts alone. Modern car design and manufacture are based on them. With the growing technology, this process will keep producing safer, cleaner, and more efficient vehicles for the world.

Gyakran ismételt kérdések

What are Die casting automotive parts?

They are parts of cars that are manufactured by forcing molten metal into a mold of steel under a lot of pressure. It is a process that produces powerful, accurate, lightweight components that are applied to vehicles.

What metals are used in automotive casting?

Aluminum, magnesium, and zinc alloys are the most popular. Metals that are used in large quantities are aluminum, which is strong and lightweight; very lightweight magnesium; and zinc, which is fine and durable.

Why is it important that there is an automotive die cast for electric vehicles?

The batteries make electric vehicles heavy. Light parts are made in automotive die casting, a nd this enhances driving range and efficiency. Battery housings and motor mounts are also done using it.

What do automakers do to guarantee that the castings are of quality (automotive castings)?

They conduct inspections, X-rays, dimensional inspection, and strength tests. This will guarantee that no casting is insecure, erroneous, or invalid.

What are the key strengths of the die casting automotive parts?

They are accurate, durable, lightweight, smooth, and economical for mass production. These advantages render them indispensable in contemporary automobile production.