The basic function of die casting is to manufacture automotive parts that are lightweight and have high efficiency. All these requirements have fulfilled with the use of magnesium die casting. Different parts castings are manufactured by using the magnesium die for making automotive parts.

All the manufacturers are focusing on making the automotive parts that have great efficiency, and they must be economical. As the world is advancing, the automotive industry is under constant pressure of manufacturing the innovative products. The magnézium ötvözetből készült öntvény has gained popularity over the years.

The evolution in the automotive industry, with the increase in production of electric vehicles (EVs), has led to great use of magnesium alloy in parts manufacturing. Some other materials could be used in the production, but magnesium is the lightest. Its use offers great advantages in the automotive industry when it is processed through high-pressure die casting.

The article explores the ideas of magnézium öntvény, its benefits in the automotive industry and applications as well. In the end, we will provide the information about the future use of the magnesium alloy in die casting in the automotive industry for automakers.

Mi az a magnézium öntés?

Before getting into the details of the applications and advantages of magnesium alloy die casting in the automotive industry, it is important to understand what magnesium die casting is. Here are the steps involved in the process. Melting the magnesium at 650degC that convert it into a liquid form.

Preparing the Mould

The initial step in the process of die casting magnesium is the preparation of the mould. The mould is made of a high-strength material. It is lined with the released agent that helps in preventing sticking molten magnesium to the mould. The final release of the automotive parts depends on this step of easy release of the products. It is very important to have a flawless mould to avoid any defects in the final product.

Injecting Molten Magnesium

The next step is the injection of the molten magnesium into the die. The automakers make sure that the alloy reaches every complex geometry of the mould to get perfect results. The pressure is maintained at around 1500 to 3000 psi during the process. This step is highly precise yet very fast to avoid hardening of the magnesium alloy.

Cooling

After the magnesium is injected into the mould, the next step is the cooling. It is important to remove the die from the material after cooling and setting. Like any other material, if the structure is complex and have bigger size, it took longer period to cool. In contrast, smaller and thin sized automobiles parts got cooled more easily. Monitored and efficient cooling is required to avoid any cracks in the magnesium die casting product.

Kidobás és befejezés

After the cooling of the magnesium in the die, the ejection from the die is the last step. The process of removing the finished product from the die is known as the ejection. Once the automotive parts are ejected carefully it need some further detailing, like removing and drilling the unwanted parts form final product for finishing.

The process of magnesium alloy die casting is essential in making complex and thin-walled automotive parts. Automakers use magnesium because it is the lightest material in the die casting industry for making innovative automotive parts for EV and modern vehicles.

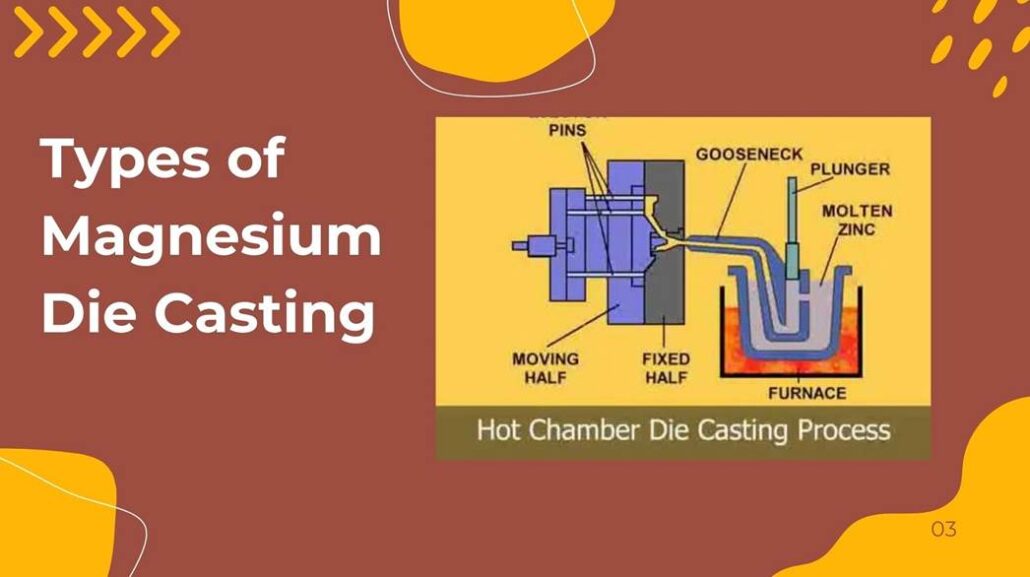

Types of Magnesium Die Casting

For making different automotive parts, there are basically two types of magnesium diecasting processes. Those are as follows;

Forró kamrás öntés

In the hot chamber, magnesium diecasting is ideal for the low melting point of magnesium. In this process, the die is submerged in the molten chamber and forced into the die.

Hidegkamrás öntés

The typical method of magnesium die casting is cold chamber die casting. In this process, the molten magnesium is injected into the unheated moulds in the automotive industry.

Why Magnesium is Best in Automotive Applications

The combination of physical and mechanical characteristics of magnesium is very special and is very much demanded in the production of vehicles.

- First, magnesium is about 33% lighter than aluminium and 75% lighter than steel. This is a radical weight cut that has an immediate effect on the efficiency, handling, and emissions of the vehicle.

- Secondly, magnesium alloys have a good strength-to-weight ratio, thereby being perfect in applications where the component must be able to withstand mechanical forces but must be light.

- Moreover, magnesium exhibits better vibration and noise damping that enhance comfort of the ride and minimizes the cabin noise.

- It is also a good thermal conductor and is therefore used in parts that are subjected to heat, like transmission housings and electronic casings, among others.

Advantages of Magnesium Die Casting

Substantial Weight Reduction on Vehicles

One of the most significant objectives of automotive engineering is weight reduction. Lightweight cars use less fuel, produce fewer emissions and provide improved performance.

Magnézium öntvény helps automakers to substitute the heavier parts made of steel or aluminum with magnesium without affecting their functionality. The slightest weight cut in each element could produce an enormous weight cut when summed up in a complete car.

This benefit is especially important in electric cars that require decreasing the weight of the body to directly affect the range of the battery and its efficiency.

Better Fuel Economy and Reduced Emissions

Fuel economy is directly influenced by the reduction of vehicle weight. Research continually demonstrates that fuel efficiency increases by 5-7% as the weight of the vehicle decreases by 10%.

With magnesium die-cast parts, automakers would find it easier to comply with the tough global emission standards. This becomes particularly significant when the governments of the countries impose the rules intended to minimize carbon emissions and develop sustainable transportation. Magnesium die casting, hence, favors economic and environmental goals.

Large strength-to-weight ratio

The myth that surrounds lightweight metals is that it reduces strength. Magnesium alloys disprove this assumption.

Recent magnesium alloys in die casting have adequate mechanical strength to be applied in automotive parts like steering columns, seat frames, gearbox housings, and structural brackets. These components should be able to withstand the stress, vibration, and thermal changes in the long term.

The manufacturers get components that are durable and lightweight through the proper choice of alloys and efficient die-casting processes.

Dimensional Accuracy and Design Flexibility

Complex and tight geometries can be produced using magnesium die casting. It is possible to make thin walls, complex forms, ribs, bosses and in-built features in one casting.

This design allows flexibility, eliminates the secondary machining and assembly, decreasing the cost of production and minimum points of failure. Multiple parts can be cast into a single die-cast part, which eases the architecture of the vehicle.

Consequently, magnesium die casting facilitates innovative designs in cars and enables manufacturing efficiency.

High-Quality Vibration and Noise Damping

Natural damping of magnesium is more than that of aluminum and steel. The property has made magnesium die-cast components especially useful in the minimization of noise, vibration and harshness (NVH) in cars.

This property is of great advantage to components such as the dashboard frame, steering wheels, and seat structures. Better NVH performance helps in improving the comfort of driving and adds to a more sophisticated user experience.

In the case of luxury and top-quality cars, such a benefit is also particularly useful.

Economical Production in Large Numbers

Magnesium alloys might seem more costly on a per-kilogram basis; however, magnesium die casting is extremely economical when it comes to mass production.

The process allows for high repeatability and cycle times and reduces the amount of material wastage. After the die is made, thousands or even millions of the same parts can be made with the same quality.

Also, the cost of machining is reduced, the number of assembly phases is minimized, and the operating cost of vehicles is lowered, compensating for the initial cost of the material. During the entire production lifetime, magnesium die casting becomes cost-efficient.

Corrosion Resistance using Modern Alloys

Many issues with magnesium corrosion have been overcome for the most part due to the development of the alloy and surface treatment.

Contemporary magnesium alloyed die castings in the automobile industry provide better corrosion resistance, particularly when it is combined with coating, paints or anodizing methods. These advancements enable magnesium components to work properly even in severe environmental factors.

Consequently, the magnesium die casting can now be used in the interior and exterior of an automobile.

Sustainability and Recyclability

Automobile production has turned to a focus on sustainability. Magnesium is a material whose recycling can be done fully; recycling magnesium uses considerably less energy than making new metal using a raw material.

Numerous car producers are also using closed-loop recycling, whereby scrap magnesium used during production is melted and reused. This minimizes wastage, energy use and environmental effects.

Magnesium die casting manufacturer in China is thus in support of the global sustainability aspirations and circular manufacturing.

Magnesium vs Other Automotive Die Casting Metals

Different materials could be used in the die casting process. Here is a summary of the properties of all materials used in manufacturing.

| Tulajdonságok | Magnézium | Alumínium | Acél |

| Vibration Damping | Kiváló | Mérsékelt | Alacsony |

| Sűrűség | Very low | Alacsony | Magas |

| Strength-to-Weight Ratio | Magas | Mérsékelt | Magas |

| Diecasting ability | Kiváló | Jó | Szegény |

| Fenntarthatóság | Magas | Mérsékelt | Alacsony |

| EV suitability | Kiváló | Mérsékelt | Alacsony |

| Alkalmazások | Highly suitable | Moderately suitable | Good suitability |

Magnesium Die Casting in the Automotive Industry

Lightweight, high-strength weight ratio and high design flexibility have made magnesium die casting a more significant factor in the automotive industry because it is lightweight. Car makers use magnesium to minimize car weights, enhance the fuel efficiency of an engine, comply with stringent emissions levels and remain safe and functional.

Interior Auto Parts

Magnesium die casting is also common in the interior parts of the automotive industry, where it is important to reduce the weight and to suppress vibration. They are used in steering wheels, steering columns, seat frames, seat risers, console brackets, radio housings, and keylock housings. The inherent vibration-damping characteristics of magnesium help to enhance the ride quality and decrease the total weight of the vehicle.

Body and Structural Parts

Magnesium die casting is used in body and structural applications in lightweight but stiff construction of vehicles. Particles like door and liftgate inside panels, roof frames, mirror brackets, spare tire carriers, fuel filler lids and door handles are often manufactured with magnesium alloys. These sections enhance better fuel economy and car handling.

Framework and Control Components

There is a need to have strength and precision in making the framework and control components. Some of the parts that will use magnesium to its advantage are brake pedal arms, accelerator pedals, clutch pedals, pedal brackets, mounting brackets and racing wheel components. The apps are used to enhance the responsiveness of the vehicles without interfering with the safety.

Powertrain and Electric Vehicle Parts

Magnesium die cast is used in the powertrain system for engine blocks, cam covers, valve covers, clutch housings, transfer cases, alternator housings, and electric motor housings. In the case of electric and hybrid cars, magnesium is important in decreasing structural weight and thermal management, which boosts performance and driving range.

Magnesium Alloy Types in Automotive Die Casting

| Magnesium alloy | Usage |

| AZ91D Magnesium Alloy | In the automotive industry, the most common magnesium die-cast alloy is AZ91D. It has a high level of castability, a high level of corrosion resistance and good level of mechanical properties, hence it finds application in housing, covers, and structural automotive components. |

| AM60B Magnesium Alloy | Such alloys are used in instances where more ductility, impact resistance, and toughness are needed. |

| AM20 Magnesium Alloy | They are popular in safety-critical components like steering wheels, seat frames and crash-sensitive components. |

| AM50A Magnesium Alloy | Reduction of aluminum enhances elongation, enabling the alloys to be able to absorb energy during impact. |

Through the correct magnesium alloy and die casting, automotive manufacturers can obtain lightweight, safe and high-performance automotive components, and thus magnesium die casting is one of the pillars of the current automotive engineering.

Outlook in Magnesium Die Casting in the Automotive Industry

Lightweight, electric and sustainable are the future of automotive manufacturing. These trends are suitably matched by Magnesium die casting.

With the increasingly precise regulations and the changing design of vehicles, magnesium elements will become more and more popular among automakers to meet performance and efficiency goals. Mass production structural castings, high technology alloys and intelligent factories will further increase the role of magnesium.

Magnesium die casting is no longer a niche technology – it is a staple of the newer automotive engineering.

Következtetés

Magnesium die casting in the world, however, presents a high performance in terms of lightness, structural stability, design, capability and sustainability. It offers a solution that is well-tested and progressive to the automotive manufacturers who aim to cut weight, increase fuel efficiency, comfort, and environmental standards.

In traditional internal combustion vehicles, magnesium die-cast components are defining the future of the transportation industry. With the increased technology and the scale of production, the benefits of magnesium die casting in the automotive industry will keep increasing.

To conclude, magnesium die casting is not just an option in materials selection, but it is a strategic asset in the changing world of automobile design.