Gesmeed aluminium is een van de meest vertrouwde materialen in de hedendaagse engineeringpraktijk. Het wordt gevormd door massief aluminium te persen met een hoge hoeveelheid hitte en druk. Hierdoor verandert de interne structuur van het metaal en wordt het sterker en taaier dan gegoten aluminium. Daarom gebruiken industrieën die veiligheid en duurzaamheid vereisen, gesmeed aluminium. Aluminium op zich is al beoordeeld als lichtgewicht, bestand tegen corrosie en veelzijdig. Het is aanwezig in voertuigen, vliegtuigen, gebouwen, elektronica en zelfs in gewone gereedschappen. Maar niet alles wat van aluminium is gemaakt, is hetzelfde. De prestaties van het metaal worden direct beïnvloed door de manier waarop het metaal wordt gevormd.

Bij het gieten wordt aluminium gesmolten en in mallen gegoten. Dit kan gebreken veroorzaken zoals luchtbellen en gaten. Smeden elimineert deze problemen. In plaats van te smelten, wordt het aluminium in vorm geperst zodat de korrel gedwongen wordt zich aan te passen aan het ontwerp van het onderdeel. Dit levert een zeer krachtig en homogeen materiaal op.

Gesmeed aluminium is populair geworden nu de industrie verschuift naar lichtere, veiligere en efficiëntere oplossingen. Dit artikel vertelt ons waarom het beter is dan gegoten metaal, het proces dat betrokken is bij het smeden van metalen, waar het wordt toegepast en de toekomst van het smeden van aluminium.

Inhoudsopgave

SchakelWat is gesmeed aluminium?

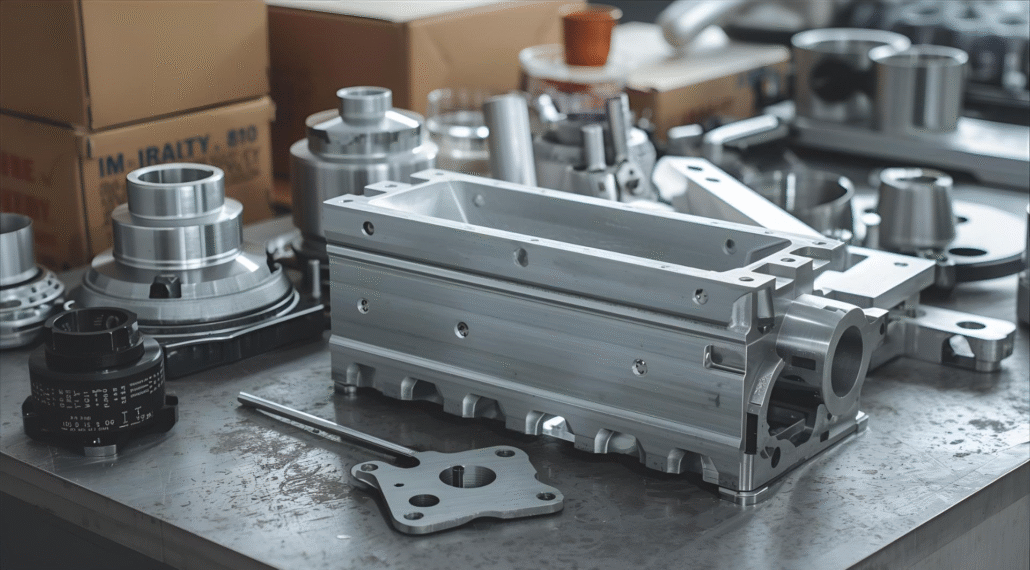

Gesmeed aluminium wordt gemaakt door massief aluminium onder hoge druk te persen. Het metaal wordt niet helemaal gesmolten zoals bij gieten. Het wordt eerder verwarmd tot het zacht en kneedbaar wordt. Nadat het zacht is geworden, wordt het aluminium met behulp van zware smeedmachines in de vereiste vorm gestampt of geslagen. Door deze spanning wordt het metaal platter en worden ook de interne korrels geperfectioneerd. De korrel is georiënteerd in de vormrichting en draagt bij aan de betere sterkte en taaiheid van het onderdeel. Zo'n fijne structuur verwijdert ook tal van defecten die aanwezig zijn in gegoten aluminium, zoals poriën of scheuren. Bijgevolg is gesmeed aluminium veiliger, duurzamer en sterker.

Hoe werkt een aluminiumsmederij?

Smeden gebeurt in een aluminium smederij. Er zijn een paar stappen in het proces:

- Verwarming - De aluminium billet wordt verhit tot hij zacht is, maar niet smelt.

- Vormgeven - De hete billet wordt in een smeedpers/hamer geplaatst. De vereiste vorm wordt veroorzaakt door hoge druk.

- Koeling - Bij het forceren koelt het gesmede onderdeel gecontroleerd af om de sterkte te behouden.

- Afwerking - Voor meer nauwkeurigheid kunnen extra bewerkingen of warmtebehandelingen worden uitgevoerd.

Dit proces resulteert in een dik, stevig en homogeen deel. Het heeft geen zwakke plekken of luchtbellen zoals gieten.

Voordelen van gesmeed aluminium

Gegoten metaal en andere materialen kunnen niet wat gesmeed aluminium kan. Het is het gereedschap bij uitstek geworden in industrieën waar we ons geen compromissen kunnen veroorloven op het gebied van prestaties en veiligheid.

Superieure kracht

Gesmeed aluminium is erg sterk en dit is een van de belangrijkste voordelen van gesmeed aluminium. De korrelstructuur van het metaal wordt verfijnd door het smeedproces. De trek- en vermoeiingssterkte worden door deze afstemming verbeterd. Valse onderdelen kunnen herhaaldelijk zware belastingen en spanningen verdragen zonder defect te raken. Hierdoor zijn ze ook zeer geschikt voor krachtige activiteiten zoals landingsgestellen voor vliegtuigen, ophangingssystemen en industriële machines.

Lichtgewicht maar sterk

Aluminium is inherent lichter dan staal en het smeden gaat nog dieper. Gesmeed aluminium is erg sterk voor zijn gewicht. Hierdoor kunnen ingenieurs ervoor zorgen dat ze lichtere machines en voertuigen maken die nog steeds veilig en sterk zijn. Het gewichtsverlies maakt auto's en vliegtuigen zuiniger, maar geeft ze ook duurzaamheid.

Verhoogde weerstand tegen vermoeidheid

Gegoten onderdelen slijten veel meer dan gesmeed aluminium. Vermoeiing is een toestand waarbij een onderdeel versleten is door meerdere spanningscycli. Door de zwakke korrelstructuur hebben gegoten onderdelen de neiging om te barsten. Gesmeed aluminium barst niet snel en dus zullen onderdelen van dit materiaal lang meegaan in de handen van degenen die ze gebruiken.

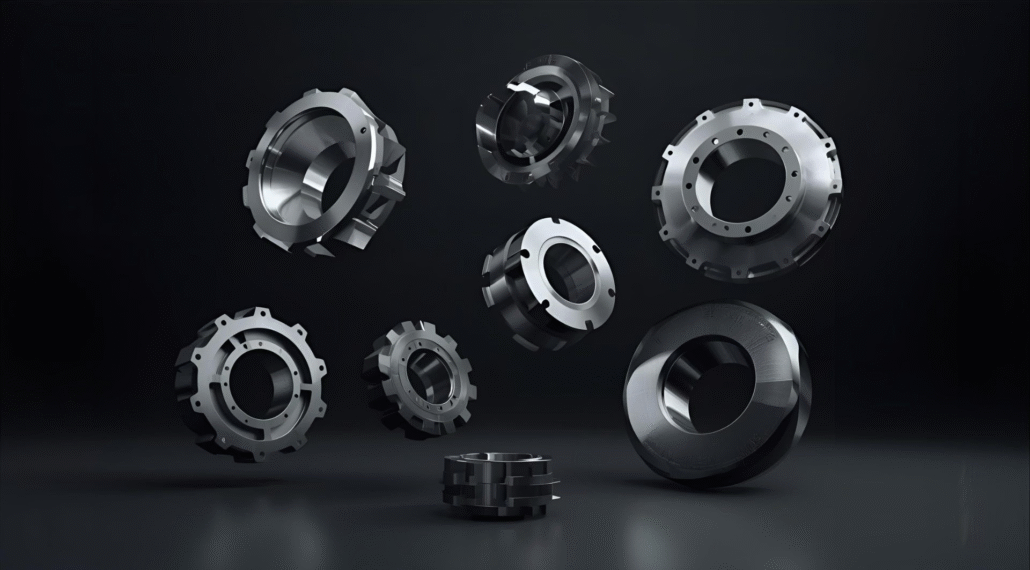

Uniforme korrelstructuur

Het smeedproces wordt gebruikt om de vorm van het onderdeel af te stemmen op de korrel in het metaal. Zo'n homogene korrelstructuur maakt het harder en moeilijker om te slaan. Gieten daarentegen geeft willekeurige korrelstructuren die zwakke plekken creëren.

Veiligheid en betrouwbaarheid

Veiligheid is de eerste prioriteit in hoge druk industrieën zoals lucht- en ruimtevaart, auto's en defensie. Gesmeed aluminium is betrouwbaar omdat het kracht, hardheid en stabiliteit biedt, zelfs onder extreme omstandigheden.

Toepassingen voor het smeden van aluminium

Het smeden van aluminium heeft indruk gemaakt in de wereld waar gewichtloze, krachtige en duurzame onderdelen nodig zijn. Van gesmede aluminium onderdelen wordt aangenomen dat ze veilig zijn en daarom wordt er vaak op vertrouwd in kritieke toepassingen die te maken hebben met veiligheid.

Auto-industrie

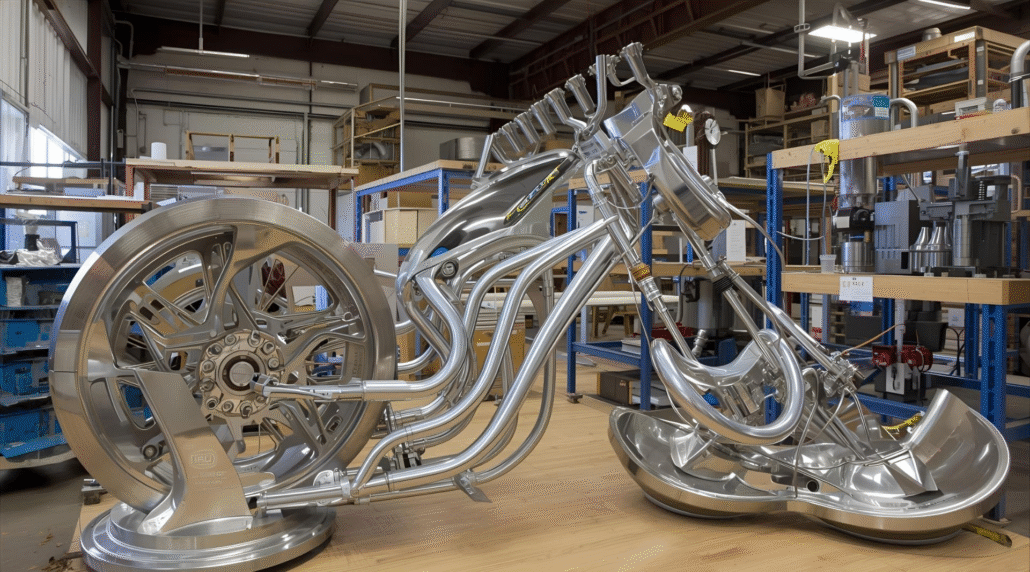

Moderne auto's zijn betrokken bij frauduleus aluminium. Een veel voorkomende toepassing is in wielen. In vergelijking met gegoten wielen zijn gesmede wielen lichter, duurzamer en veiliger. Dit soort gewichtsverlies verbetert de wendbaarheid en brandstofefficiëntie. Ophangingsonderdelen zijn een andere belangrijke toepassing die bestand moeten zijn tegen zware belastingen, schokken en trillingen op de weg. Het gebruikte aluminium is gesmeed, dus ze worden niet belast. Bovendien zijn de meeste motoronderdelen, waaronder drijfstangen en zuigers, gesmeed. Deze onderdelen zijn bestand tegen hoge druk en hete temperaturen met een lange levensduur. Kortom, gesmeed aluminium verbetert de prestaties en veiligheid van de auto.

Ruimtevaartindustrie

Vliegtuigen hebben onderdelen nodig die licht van gewicht en sterk zijn. Gesmeed aluminium voldoet aan deze specificatie. Het is van toepassing op landingsgestellen die bestand moeten zijn tegen grote schokken tijdens het landen en opstijgen. Het komt ook voor in vleugelstructuren waar efficiëntie afhangt van lichtheid. Onderdelen van gesmeed aluminium hebben te maken met druk, hitte en trillingen in vliegtuigmotoren. Falen is geen optie tijdens de vlucht; daarom vertrouwt de lucht- en ruimtevaartindustrie op smeden.

Militair en defensie

Defensietoepassingen vereisen gesmeed aluminium. Gesmede onderdelen van tanks, vliegtuigen en marineschepen moeten de extreme gevechtsomstandigheden doorstaan. Smeden garandeert maximale taaiheid, sterkte en betrouwbaarheid, zelfs onder de zwaarste omstandigheden.

Industriële machines

Belangrijke apparatuur werkt meestal op volle belasting. Producten van gesmeed aluminium zijn slijtvast en minimaliseren de stilstandtijd. Dit maakt ze kosteneffectief en lange termijn oplossingen voor fabrikanten.

Sport en Lifestyle

Voor sport- en lifestyleproducten wordt ook gesmeed aluminium gebruikt. Gesmede onderdelen worden gebruikt om hoogwaardige fietsen, klimtoestellen en sportuitrustingen te maken. Dergelijke voorwerpen moeten licht en duurzaam zijn gedurende een lange periode en daarom is smeden de beste methode.

De reden waarom industrieën smeden gebruiken in plaats van gieten?

Smeden is de optie van de industrie boven gieten omdat het betrouwbaar en veilig is. Tijdens het afkoelingsproces kan gegoten aluminium gebreken gaan vertonen. Zaken als poreusheid, krimp en een slechte korrelstructuur vormen zwakke punten in het materiaal. Dergelijke zwakke punten vergroten de kans dat een gegoten onderdeel barst of breekt als gevolg van stress.

Gesmeed aluminium is vrij van deze problemen. Door het smeden kan het metaal worden verdicht, kunnen de korrels worden verfijnd en kunnen de interne delen van het metaal worden verwijderd. Hierdoor ontstaat een hardere en dikkere sectie die beter bestand is tegen vermoeiing. Gesmede wielen kunnen bijvoorbeeld een klap en een groot gewicht verdragen zonder te breken, terwijl gegoten wielen kunnen verbuigen of breken wanneer hetzelfde gebeurt.

Het onderscheid is letterlijk van levensbelang in kritieke sectoren zoals de lucht- en ruimtevaart, de auto-industrie en defensie. Militaire apparatuur, ophangingsarmen en landingsgestellen van vliegtuigen zijn niet bestand tegen een plotselinge storing. Daarom geven fabrikanten de voorkeur aan smeden. Het biedt de kracht, hardheid en betrouwbaarheid die niet te vinden is in gieten.

Problemen bij het smeden van aluminium

Ondanks het feit dat smeden betere prestaties levert, gaat het gepaard met enkele moeilijkheden. Dit zijn hogere prijzen, ontwerpbeperkingen en een langere productietijd.

Hogere kosten

Bij het smeden zijn gereedschapssystemen, zware persen en ovens nodig. Dit zijn machines die veel energie verbruiken en bekwame operators nodig hebben. Daarom is smeden duurder om mee te beginnen dan gieten. Dit kan een nadeel zijn voor producten met een lage waarde of een laag budget.

Complexe vormen

Het voordeel van gieten is dat het ook mogelijk is om gesmolten aluminium in gedetailleerde vormen te gieten. Smeden, op zijn beurt, vormt massief metaal onder druk, en dat creëert een beperking op het ontwerp. Deze uitvindingen verminderen afval, verbeteren de kwaliteit en doen meer dan gesmeed aluminium.

Langzamere productie

Smeden gaat niet zo snel als gieten. Elk onderdeel moet apart verhit, geperst, gekoeld en verfijnd worden. Productiegieten in grote volumes maakt de productie van meerdere onderdelen tegelijk mogelijk en is dus sneller.

Waarom smeden nog steeds wint

Toch is gesmeed aluminium het materiaal bij uitstek in de luchtvaart-, auto-, defensie- en zware machine-industrie. Kosten of snelheid zijn in deze industrieën niet van groot belang, maar wel veiligheid en duurzaamheid. Gesmeed aluminium is betrouwbaar genoeg om de extra investering te rechtvaardigen.

Ontwikkeling in het smeden van aluminium

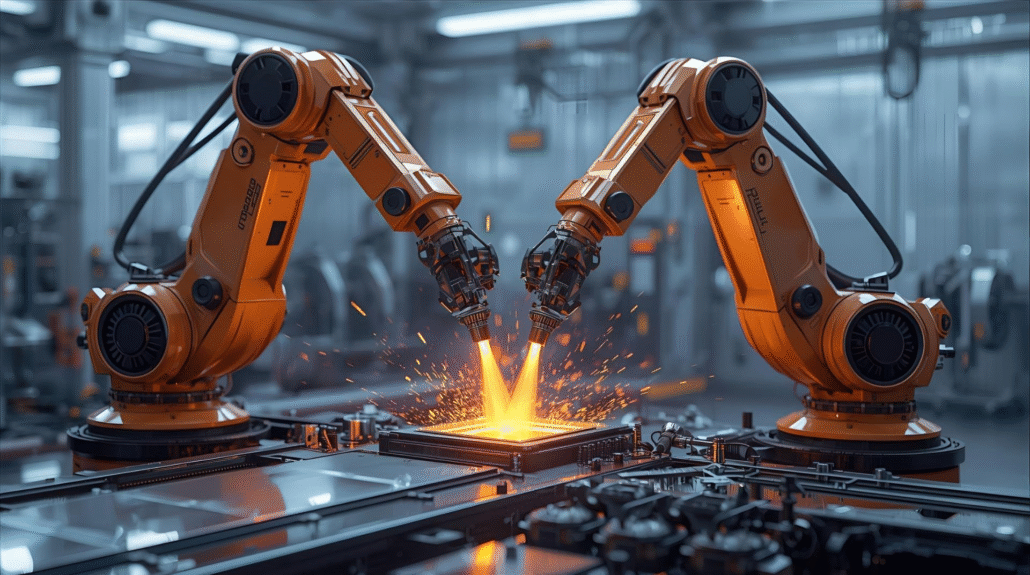

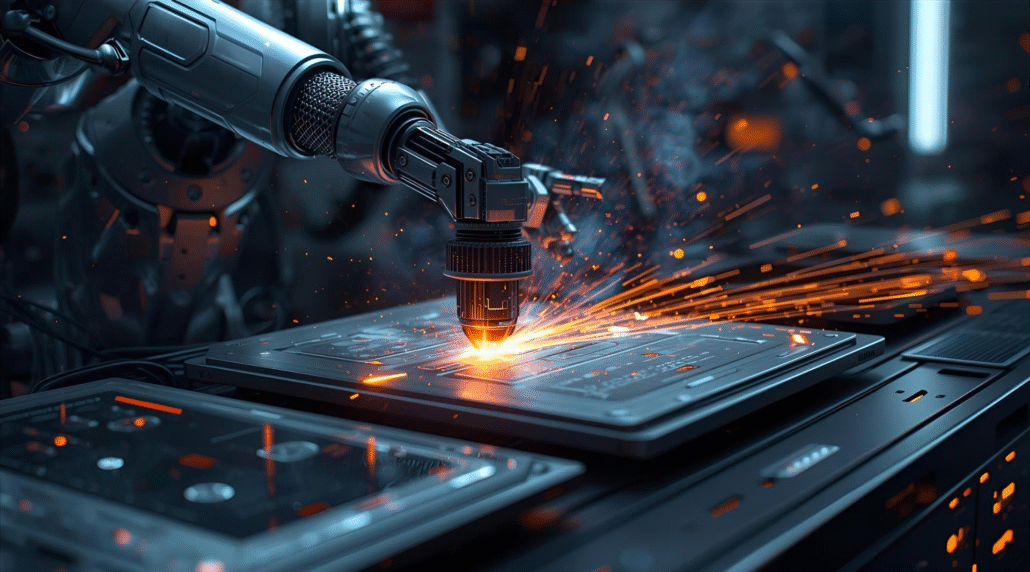

De huidige technologie verandert het smeden van aluminium in een efficiënter, nauwkeuriger proces. CNC-bewerking zorgt voor nauwkeurige afmetingen en oppervlaktekwaliteit.

Computersimulatie

De korrelstroom, spanningspunten en materiaalgeleiding kunnen nu worden voorspeld met simulatiehulpmiddelen tijdens het smeden. Deze versterkingsmethode verbetert de sterkte, de oppervlakteafwerking en de hardheid. Er ontstaat minder afval, wat materiaal en kosten bespaart.

Integratie CNC-bewerking

Veel onderdelen moeten na het smeden nog verder worden afgewerkt. Smeden met 3D-geprinte aluminium preforms is een van de beschikbare innovaties. 3D-geprinte aluminium preforms kunnen worden gesmeed om ze sterker en dichter te maken. CNC in combinatie met smeden stelt fabrikanten in staat om gecompliceerde onderdelen van extreem hoge kwaliteit en consistentie te maken.

Hybride smeedmethoden

Andere fabrikanten maken geen onderscheid tussen smeden en gebruiken geen andere productiemethoden zoals machinale bewerking of warmtebehandeling. Naarmate de technologie zich blijft ontwikkelen, zal het smeden van aluminium een essentieel onderdeel blijven in de auto-industrie, ruimtevaart en industrie. Het maakt ook de productie mogelijk van onderdelen met nichecapaciteiten in de hoogtechnologische industrieën.

3D printen plus smeden

Hierdoor is gesmeed aluminium een alternatief voor andere industrieën die hun ecologische voetafdruk willen verkleinen. Het proces maakt de productie mogelijk van bijna-nettovormen die licht en sterk zijn.

De toekomst uitbreiden

Deze ontwikkelingen verlagen de productiekosten en bieden toegang tot nieuwe ontwerpmogelijkheden.

Milieu-impact

Gesmeed aluminium is ook groen. Dit is waarom:

- Duurzaamheid - Hoe langer het meegaat, hoe minder vervangingen.

- Recyclebaarheid - Het aluminium kan onbeperkt worden gerecycled zonder dat het wordt aangetast.

- Energiebesparing - Het smeden van gerecycled aluminium bespaart energie in vergelijking met het delven van nieuw materiaal.

Het zijn ongezonde dingen die verzwakken en destabiliseren.

Gesmeed aluminium vergeleken met anderen

Gesmeed aluminium vs. gegoten aluminium

Gegoten aluminium is minder duur en zwakker. Het heeft kleine luchtbellen en koelfouten. Dat maakt aluminium populairder in situaties met hoge druk, en magnesium wordt in feite veel gebruikt als het vooral bedoeld is om gewicht te besparen. Gesmeed aluminium is persvormig. De korrel beweegt mee met de vorm, waardoor het harder en zwaarder wordt. Gesmeed aluminium is altijd superieur in het geval van onderdelen die cruciaal zijn voor de veiligheid.

Gesmeed aluminium vs. staal

Staal is krachtiger dan aluminium en het is veel zwaarder. Dit hogere gewicht verlaagt de auto en verlaagt de brandstofefficiëntie. Gesmeed aluminium is echter nog steeds populair vanwege de verhouding tussen kosten, sterkte en duurzaamheid. Het kan nooit hetzelfde staal zijn in pure sterkte, maar het biedt veel taaiheid tegen een fractie van het gewicht. Daarom gebruiken de luchtvaart- en auto-industrie meestal gesmeed aluminium in plaats van staal.

Gesmeed aluminium vs. titanium

Titanium is een zeer taai en niet-corrosief metaal. Maar het is ook duur en moeilijker te bewerken. Gesmeed aluminium is goedkoper en kan gemakkelijk worden gevormd. Titanium wordt niet volledig vervangen door aluminium, maar in de lucht- en ruimtevaart en defensie is het gebruik ervan beperkt tot onderdelen die sterk moeten zijn, maar niet veel massa nodig hebben en daarom kan het beter worden vervangen door aluminium.

Gesmeed aluminium vs. magnesium

Magnesium is goedkoper dan aluminium en is niet zo sterk. Het kan gemakkelijk corroderen en heeft een lage weerstand tegen vermoeiing. Aluminium kan worden gesmeed om meer sterkte en een langere levensduur te bieden. De fabricage kan krachtiger en karakteristieker worden gemaakt dan gegoten aluminium dat gebreken zoals porositeit en niet-uniformiteit in de korrelstructuur bevat.

Gesmeed aluminium vs. koolstofvezel

Koolstofvezel is extreem licht en zeer krachtig. Maar het is erg duur om te produceren en moeilijk te repareren. Gesmeed aluminium is goedkoper, eenvoudiger te bewerken en kan worden gerecycled. Koolstofvezel is geselecteerd op basis van prestaties in specifieke industrieën. De lichtgewicht sterkte en lange levensduur van aluminium smeden zal de aluminium smeedindustrie in de toekomst een boost geven.

De toekomst van aluminium smeden

De combinatie van smeden en 3D-printen heeft nieuwe mogelijkheden geboden en de productie van lichtere en sterkere ontwerpen mogelijk gemaakt. Deze vraag wordt beïnvloed door verschillende trends over de hele wereld.

De eerste reden is de verschuiving naar elektrische voertuigen (EV's) in een indrukwekkend tempo. EV's hebben onderdelen nodig die het totale gewicht van het voertuig laag houden zonder de veiligheid te beïnvloeden. Hieraan wordt voldaan door gesmeed aluminium, dat een hoge sterkte-gewichtsverhouding kan bieden. Smeden is het proces van het afstemmen van de korrelstroom op de vorm van het onderdeel door middel van gecontroleerde hitte en druk om onderdelen te vormen die bestand zijn tegen zwaar gewicht, herhaaldelijke stress en ongunstige omstandigheden. Gesmede onderdelen zoals wielen, ophangingsarmen en batterijhouders zullen een grotere rol gaan spelen naarmate EV meer ingang vinden.

Er is ook de groei van de lucht- en ruimtevaartindustrie. Luchtvaartmaatschappijen plaatsen een groter aantal orders voor vliegtuigen om te voldoen aan de toename van het aantal passagiers en defensieprogramma's vragen om geavanceerde straaljagers en drones. Gesmeed aluminium is het belangrijkste ingrediënt in deze industrie, omdat landingsgestellen, vleugelstructuren en motoronderdelen extreem sterk maar extreem licht moeten zijn.

Een andere laag van de vraag zijn de extra militaire en defensie-uitgaven. Tanks, pantservoertuigen, schepen en vliegtuigen die in de moderne wereld worden gemaakt, vereisen materialen die bestand zijn tegen extreme gevechtsomstandigheden. Gesmeed aluminium biedt de stabiliteit en sterkte die onder dergelijke omstandigheden vereist zijn.

Conclusie

Gesmeed aluminium is een van de meest betrouwbare onderdelen van de moderne productiewereld. Daarom moet gesmeed aluminium worden gebruikt in industrieën die veiligheid en prestaties het belangrijkst vinden. Automobieltoepassingen van gesmede wielen, ophangingssystemen, motoronderdelen, enz. omvatten onderdelen die het brandstofverbruik en de stabiliteit van bestuurders verbeteren.

Het zal de basis vormen van engineering en innovatie van de toekomst, omdat er niets krachtiger, veiliger en duurzamer is. De combinatie van 3D-printen en smeden biedt nieuwe mogelijkheden en vandaag de dag kunnen we lichtere en krachtigere ontwerpen maken. Van gesmede landingsgestellen, vleugelstructuren en turbinedelen die in de lucht- en ruimtevaart worden gebruikt, wordt verwacht dat ze extreme krachten overleven. Defensie is een andere industrie die gesmeed aluminium nodig heeft in tanks, vliegtuigen en marinesystemen, waar falen geen optie is.

Smeden kost momenteel meer en neemt meer tijd in beslag dan gieten, maar de vooruitgang in de technologie, waaronder computersimulaties, CNC-bewerking en hybride productie, maakt de procedure efficiënter. Het vormt de basis van de volgende generatie engineering en innovatie, omdat niets de combinatie van kracht, veiligheid en duurzaamheid kan evenaren. Gesmeed aluminium zal een belangrijke grondstof blijven naarmate industrieën over de hele wereld veranderen. De reden waarom engineering en innovatie een veelbelovende toekomst hebben, is dat de kracht, veiligheid en duurzaamheid niet kunnen worden geëvenaard.