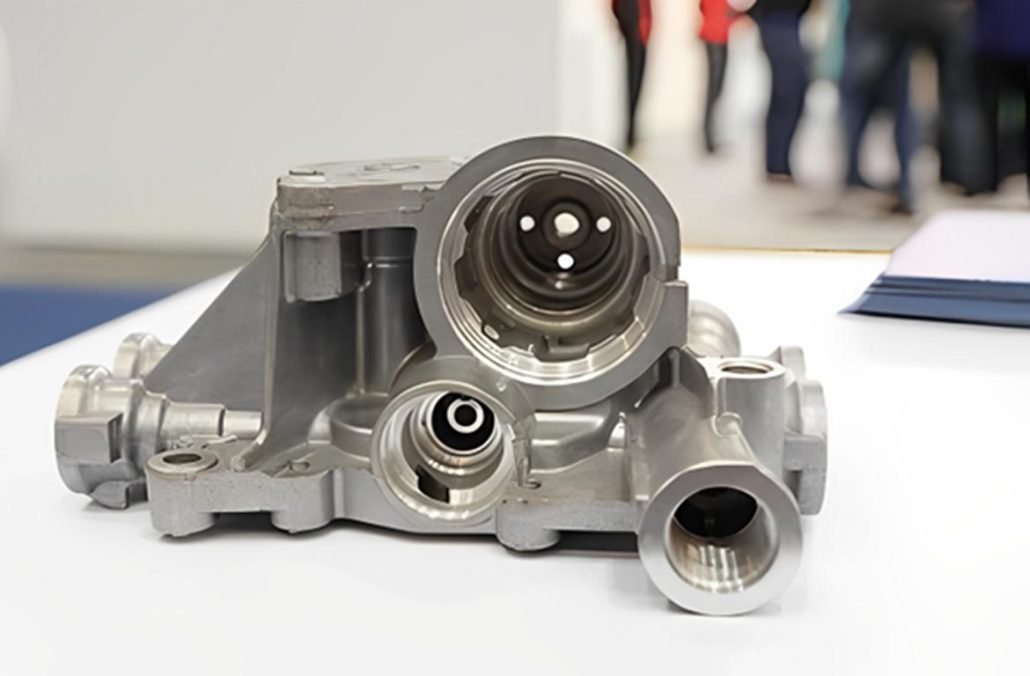

Find Right Aluminum Die Casting Sources Are you looking for the high quality and ultimate die casting services for your business? Well, you better need to hire the right service provider who must be experienced in the very same domain. Yes, it is highly necessary to invest some time who can offer very high-quality results and that is by paying the very affordable amount. Before we talk about how to find the right company, it is highly necessary to know more about Die casting. Well, this is the most important manufacturing technology which is used by many industries which are looking for all sorts of parts to commence the work and for that it is necessary to go with the aluminum die casting process. With the help of die casting mold, it will help in molding the complexity of the metal substance exactly in the same manner as you are looking to have. Yes, the final product can have virtually any size depending on what designer desires, thus there is nothing impossible for the best and great service providers at all. When it comes to finding a right service provider for aluminum casting parts, you better invest time over the net and find out the most experienced, reliable and friendly service provider to meet the exact requirements without any fail. Also, you better find out someone who can easily work on any customized requirements of the clients as well as they must possess great goodwill in the market. Also, you can investigate their previous projects and check how best they are in the die casting and how they have helped other companies to complete their requirements. Not only this, even, you need to disclose them the complete information about your project requirements and check how well they are in offering you the correct guidance as well as what price they are quoting you up. Even, you can do this with different sources and go up with the best one who offers great services at the best prices. Moving up with the pro means they will consider mechanical properties, including tensile strength, yield, impact, hardness, and other various specifications in advance to offer you the best solutions. Not only this, pros will help in picking up the right metal which they perform by checking out the physical properties of the metal. Yes, before going up with the aluminum die casting, it is very important to know more about its conductivity or how it behaves under extreme stress or heat. Pros also determine the composition of different alloys, check what are the common uses for the primary element, they also check out a complete list of die-cast alloys, check out the needed properties, and everything to offer you something the best to meet your exact requirements. Why don’t you check out to go to the suggested source? Well, it will offer you the best services by offering you the casting of metal in the shortest possible of time, will make everything from the scratch and the best part is everything will be done in a budget-friendly manner. Technology is improving day by day and we are the one enjoying it up fully. Today, we can have every possible thing to make our work the best as well as offer us full convenience and complete peace of mind. Apart from others, talking about Die casting, it is a manufacturing process that can produce geometrically unique and impossible metal parts with the best use of reusable molds, called dies. The die casting process is very important and pros always make sure to use all the necessary things, called- furnace, metal, die casting machine, die and other various materials. The metal which is used here is always non-ferrous alloy, like- Zinc and aluminum, later it is melted in the furnace and then injected into the dies in the die casting machine for producing very complex metal parts. It is always better to approach the right company for aluminum casting parts as they always go with the best and authentic procedures in order to produce something the best. They may use different types of die casting machines, called – hot chamber machines and cold chamber machines for a perfect die casting solution. Hot chamber machines are used for those alloys which have low melting temperatures, such as zinc. And Cold chamber machines are used for those alloys with high melting temperatures, such as aluminum. Both machines work the same and once they are done with the molten metal, they inject the same into the dies, wait for cooling it down and solidify into the final part, called the casting. Aluminum die casting tooling is also known as dies, is here just for alloying the steel. The dies are finished from at least two sections to allow casting elimination. To do so, there is a special need of the efficient approach of die casting and some go with the portable slides, with certain sections that can be done without difficulty to build the ideal shape as demanded by clients from die casters. In the procedure, die casting tooling goes with the simple production of the holes through the predetermined die half. Once we have the molten metal, it is then dispensed into the hole in order to dry in the cavity and this is the best way to get the specific dimensions contoured in the plating. Dies may also have to lock pins, which are utilized in order to stick together two halves and to take away the cast part. Always find the best and reliable service provider for aluminum die casting as well as who can easily manufacture miniature to large precision components using the broad range of zinc die casting, aluminum and magnesium die casting alloys. It is important to know that each and every alloy has unique physical characteristics to match your specific application. However, it is highly necessary to find out the right experts who can help you to meet your requirements by picking up the ideal material to manufacture your precision component.