Obsah

PřepínáníIntroduction to Die Casting of Aluminum

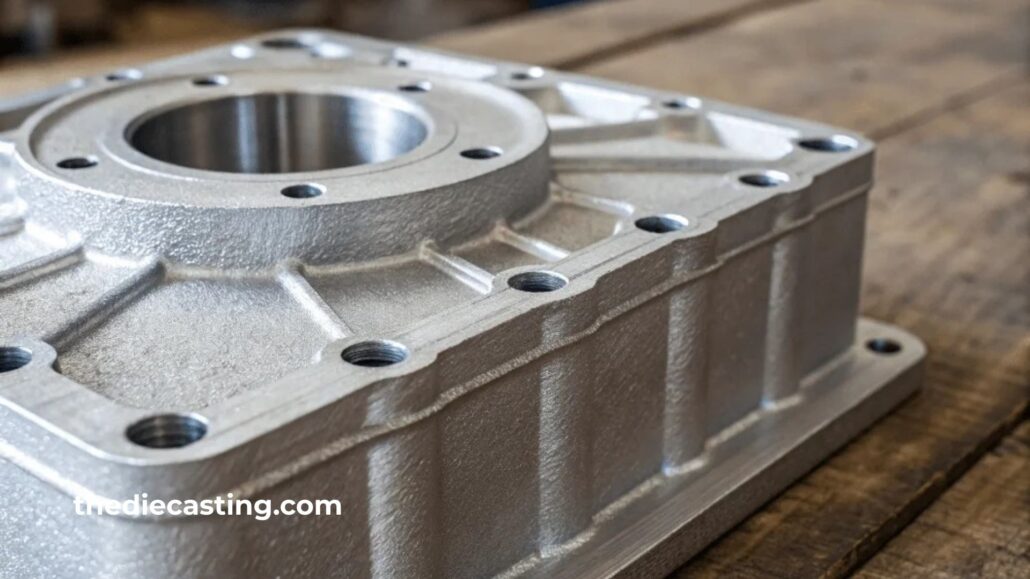

Tlakové lití hliníkové slitiny is a highly efficient manufacturing process and is used to produce complex metal components at high volume. It is the process of injecting molten aluminum alloy into a hardened steel mold (commonly called a die) at high pressure.

The process is particularly appreciated in the automotive, electronics, telecommunications, and industrial equipment industries, as it produces lightweight components with good dimensional accuracy and surface finish.

The excellent strength-to-weight ratio is a key reason aluminum is a preferred metal for die casting. The aluminum alloy components may provide the required mechanical performance for the structural application and offer a material with a high level of product weight reduction.

There is also die casting, which enables manufacturers to incorporate multiple functions into a single part. Ribs, bosses, mounting points, and thin walls can be cast in a single operation, eliminating the need for secondary machining and assembly.

This, in turn, reduces production costs and increases consistency and repeatability. Owing to these merits, tlakové lití hliníku has emerged as one of the most popular metal-forming processes for medium- to high-volume production.

The Die Casting Process of Aluminium

Mold Preparation and Setup

It starts with preparing the steel die. The die is a two-part die casting: a stationary half and a moving half. The die cavity is sprayed and cleaned after every shot. This coating enables control of die temperature and makes the cast solid easy to eject without sticking to the mold surface or being damaged.

Molten Aluminum Injection

In a furnace, the slitina hliníku is melted and held at a controlled temperature to achieve the proper fluidity. During high-pressure die casting, a specified quantity of molten metal is injected into the die cavity at high pressure by a hydraulic piston. The pressure may range from several thousand to more than 20,000 psi, allowing the metal to fill small areas and complex geometries before solidification.

Tuhnutí a chlazení

Pressure is kept after filling up the cavity until the aluminum cools and solidifies. The rapid cooling of the steel die yields a fine microstructure that enhances mechanical properties and surface finish. Channel cooling within the die regulates temperature and ensures consistent cycle times.

Vyhazování a dokončování

When the die is hardened, the halves open, and the die is ejected from the mold by ejector pins. Any unnecessary material, including runners, gates, and flash, is trimmed. Secondary operations, such as machining, surface treatment, or heat treatment, may then be performed on the part, depending on the application. The result is a near-net-shaped aluminum part suitable for demanding industrial applications.

Aluminum Alloys in Die Casting

Alloy-based castings: Aluminum die-casting alloys are designed to balance castability, mechanical strength, corrosion resistance, and thermal performance. In contrast to pure aluminum, these alloys have controlled levels of silicon, copper, magnesium, iron, and other alloying elements to enhance liquid flow, solidification, and serviceability of the molten metal. Selecting an appropriate alloy is essential, since each composition offers a unique balance of strength, durability, weight, cost, and manufacturability.

This is a closer examination of the most popular high-performance aluminum die-casting alloys and what makes each one suitable for a particular application.

A380 Aluminum Alloy

Mechanical Performance and Strength

A380 has been referred to as the workhorse of tlakové lití hliníku. It has good tensile strength (approximately 320 MPa) and yield strength (approximately 160 MPa) in the as-cast form. Although not the best aluminum alloy on the market, it offers the best combination of strength and ductility for structural housings, covers, and brackets.

Výhody

- The best thing about the A380 is its high castability.

- Its silicon and copper content enable it to be easily transferred into complex molds to create parts with thin walls and fine details.

- It is also thermally conductive and moderately wear-resistant.

- It has a low scrap rate and good tool life due to its consistent casting process, thereby lowering overall manufacturing costs.

- The trade-offs include moderate corrosion resistance due to the copper present.

A360 Aluminum Alloy

Mechanical Performance and Strength

A360 offers the same tensile strength as A380 and has improved performance at higher temperatures. The yield strength is typically 170 MPa, and this aluminum alloy is stable under hot-working conditions, such as in engine compartments.

Výhody

- Its primary strength is high corrosion resistance.

- The reduced copper content and increased silicon and magnesium levels will enable A360 to perform effectively in wet, seawater, or chemically aggressive conditions.

- It is also highly pressure-tight and therefore a good material for hydraulic components and sealed housings.

- Nevertheless, the production of A360 is more difficult to cast than that of A380, which may complicate and increase production costs.

ADC12 (A383 Equivalent) Aluminum Alloy

Mechanical Performance and Strength

The counterpart of A383 is ADC12, which is of moderate strength, and the tensile strength is commonly 180230 Mpa. Although a bit weaker than the A380, it is still sufficient for the structural performance of numerous industrial and automotive components.

Výhody

- Excellent fluidity is its significant advantage.

- Increased silicon content enables ADC12 to cast extremely thin and complicated geometries with fewer defects.

- This is suitable for complex housings, covers, and fine-tuning parts.

- It machines readily and offers good dimensional stability.

- Corrosion resistance is also decent, and high-temperature strength is limited compared with A360.

Al-Si11Cu3 Aluminum Alloy

Mechanical Performance and Strength

The balanced mechanical properties characterize Al-Si11Cu3. Tensile strength is typically above 300 MPa, with good hardness and moderate ductility. It is stronger than ADC12 and is similar to A380 in most structural applications.

Výhody

- This alloy is both well castable and highly wear-resistant.

- Its unique silicon structure makes it hard and durable, making it suitable for use in parts exposed to friction, such as gear housings and engine components.

- It is also thermally conductive and pressure-tight.

- It has moderate corrosion resistance due to its copper content, but its versatility has led to its use in the automotive, electrical, and general engineering sectors.

B390 Aluminum Alloy

Mechanical Performance and Strength

B390 has been manufactured to be as hard and wear-resistant as possible. It has an incredibly high yield strength (approximately 240 MPa) and a tensile strength of 350 MPa. It is hard enough, up to 120 Brinell, which is very high by the standards of most die casting alloys.

Výhody

- The high silicon content leads to the formation of hard silicon particles that provide excellent abrasion resistance.

- This has made B390 the engine block and piston alloy of choice for compressor components that experience extreme friction and heat.

- It is also dimensionally stable even at high temperatures.

- Its disadvantages are very low ductility and difficulty of machining, which increase tool wear and processing costs.

Comparative Summary

The alloys of aluminum die casting are used as follows:

- The most suitable all-purpose choice will be A380 due to its strength, castability, and cost-effectiveness.

- A360 has strength in corrosion and high-temperature durability.

- ADC12 (A383) is perfect for complex and thin-walled parts.

- Al-Si11Cu3 offers equal strength and wear qualities.

- B390 is incomparable in terms of hardness and high friction.

The choice of an appropriate alloy is determined by the design factor, which may be strength, corrosion resistance, wear life, weight reduction, or casting complexity.

Summary of Physical and Chemical Properties of Aluminum Alloys

| Slitina | A380 | A360 | ADC12 / A383 | Al-Si11Cu3 | B390 |

| Silicon % | 7.5–9.5 | 9–10 | 9.5–11.5 | 9.6–12 | 16–18 |

| Copper % | 3–4 | ≤0.6 | 2–3 | 1.5–3.5 | 4–5 |

| Magnesium % | ≤0.1 | 0.4–0.6 | ≤0.3 | ≤0.35 | ≤0.1 |

| Hustota (g/cm³) | 2.71 | 2.63 | 2.70 | 2.70 | 2.75 |

| Pevnost v tahu (MPa) | ~324 | ~317 | 180–230 | ~300 | 320–360 |

| Mez kluzu (MPa) | ~160 | ~170 | ~150 | ~140 | 240–250 |

| Prodloužení (%) | ~3.5 | ~3.5 | ~3 | ~2–3 | <1 |

| Tvrdost | ~80 | ~75 | ~75 | ~85 | ~120 |

| Odolnost proti korozi | Mírná | Vynikající | Spravedlivé | Mírná | Spravedlivé |

| Odlévatelnost | Vynikající | Spravedlivé | Vynikající | Very good | Mírná |

| Odolnost proti opotřebení | Dobrý | Dobrý | Mírná | Dobrý | Vynikající |

Applications of Aluminum Alloys

Automobilový průmysl

Lightweight Structural and Powertrain Components

Automotive aluminum alloys are widely used in the manufacture of automotive engine blocks, transmission housings, suspension components, and structural brackets. They are powerful per unit weight, reducing the vehicle’s total mass and improving fuel efficiency, thereby increasing the range an electric vehicle can travel. This aluminum alloy also improves heat dissipation in engines and battery systems, enhancing performance and durability.

Aerospace Sector

Airframe structures and Interior structures

The properties that make aluminum alloys preferable in aerospace include their ability to provide strength without excessive weight. They find application in the fuselage, wing, seat frame, and interior supporting structures. The reduced weight directly improves fuel economy and load capacity without compromising safety and performance standards.

Electronics and Telecommunications

Heat Sinks and Insulating Cases

In electronics, slitiny hliníku are used for frames, heat sinks, and LED lighting frames. They also have excellent thermal conductivity, enabling effective heat dissipation and safeguarding delicate circuits, thereby extending device lifetimes. They also provide electromagnetic protection and corrosion resistance for outdoor telecom equipment.

Průmyslové stroje

Mechanical Frames and Housings

Aluminum alloys are used to make gearbox casings, pump bodies, and motor housings for industrial equipment. These sections offer dimensional stability, moderate strength, and corrosion resistance under operating conditions.

Stavebnictví a architektura

Architectural Hardware and adornments

Aluminum alloys are used in window frames, door hinges, facade panels, and architectural hardware in construction. They can be used in the structure and ornamentation of buildings and other structures due to their weather tolerance, low maintenance, and ability to support attractive surface finishes.

Choosing the Right Aluminum Alloy for Your Requirements

The final choice of the most suitable aluminum alloy for the die casting process will be based on performance requirements, production efficiency, and cost. Each alloy offers a unique combination of strength, fluidity, corrosion resistance, and wear performance, making it applicable to specific operating conditions. No single ideal alloy can be used in every application; however, the appropriate alloy can be determined by understanding the mechanical, thermal, and environmental requirements that the end component is expected to endure.

- In general-purpose structural components, A380 remains a strong choice due to its good castability, comparable strength, and cost-effective manufacturing.

- A360 offers greater pressure resistance and improved sealing for components operating in corrosive or high-temperature environments.

- ADC12 (A383 equivalent) is unique in that the complex geometry and thin walls must be accounted for, due to improved fluidity and dimensional stability.

- Alloys such as Al-Si11Cu3 offer a good balance of wear resistance and mechanical performance, making them suitable for automotive and engineering applications.

- At the same time, B390 is used preferentially when extreme wear conditions are required, especially for engine and compressor parts, where hardness and abrasion resistance are more critical than ductility.

Závěr

All the aluminum alloys have specific properties and characteristics that make them ideal for different applications. In addition to mechanical performance, aluminum die-casting alloys support current engineering objectives, including lightweight, energy efficiency, and sustainability. Their environmental friendliness and cost-effectiveness are enhanced by recyclability, corrosion resistance, and the ability to produce complex near-net-shape parts.

Aluminum die-casting alloys will be valuable materials in the automotive, aerospace, electronics, and industrial product manufacturing industries, as these industries still require materials that are lighter, stronger, and more thermally efficient.

Knowing the alloys during the design phase improves product performance, extends service life, and enables effective manufacturing processes. The selection of alloys is thus not only a choice of material, but also a choice of engineering.

Často kladené otázky (FAQ)

1. What is the most popular die-casting alloy of aluminum?

The most commonly used alloy is A380, which has high castability, reasonable strength, and affordability.

2. What is the best alloy when used in high temperatures?

A360 is a high-temperature casting alloy with higher corrosion resistance than most other die-casting alloys.

3. Which alloy do you use in thin-walled parts or complex parts?

ADC12 (the same as A383) is preferred due to its high fluidity, which enables it to fill complex molds with minimal defects.

4. Which is the highest wear resistance aluminum alloy?

B390 is highly hard and abrasion-resistant; therefore, it is used in engine blocks and other components with high friction.

5. Do die-casting alloys of aluminum contain corrosion resistance?

Yes, most of them have good corrosion resistance, but alloys with low copper content, such as A360, tend to perform better in corrosive environments.