Die casting is a metal casting process that uses high pressure to produce complex, high-volume, precise metal components with superior surface finish and dimensional accuracy. This is achieved by high-speed, high-pressure injection of molten metal into a hardened steel mold, known as a die. After the metal solidifies, the die is opened, and the completed component is ejected, trimmed, or lightly secondary processed.

Due to its speed, reproducibility, and ability to produce thin-walled, detailed casts, tlakové lití is widely used across the automotive, electronics, aerospace, appliance, and consumer products sectors.

High-pressure die casting processes fall into two major types: hot-chamber and cold-chamber die casting. Although both processes use pressure to force molten metal into a die, the ways the metal is melted, manipulated, and injected differ markedly. The differences influence the type of metals used, cycle time, production cost, tooling life, and part size.

Hot-chamber die casting integrates the melting furnace with the casting machine, enabling faster processing and improved suitability for low-melting-point alloys. In cold-chamber die casting, however, a separate furnace is used, and molten metal is poured into the machine each time. This arrangement is preferable when the alloy has a higher melting point, e.g., aluminum and copper.

Knowledge of the differences between these two processes helps Tlakové odlitky Čína select the most effective, cost-effective, and technically viable method for the company’s application.

Obsah

PřepínáníHot Chamber Die Casting: Process and Technical Knowledge

Hot-chamber die casting is a high-pressure metal casting process primarily used for low-melting-point alloys. It has extensive applications in the automotive hardware, electronics, telecommunications, and consumer goods industries, as well as in sectors that require high production speeds, tight dimensional tolerances, and good surface finish.

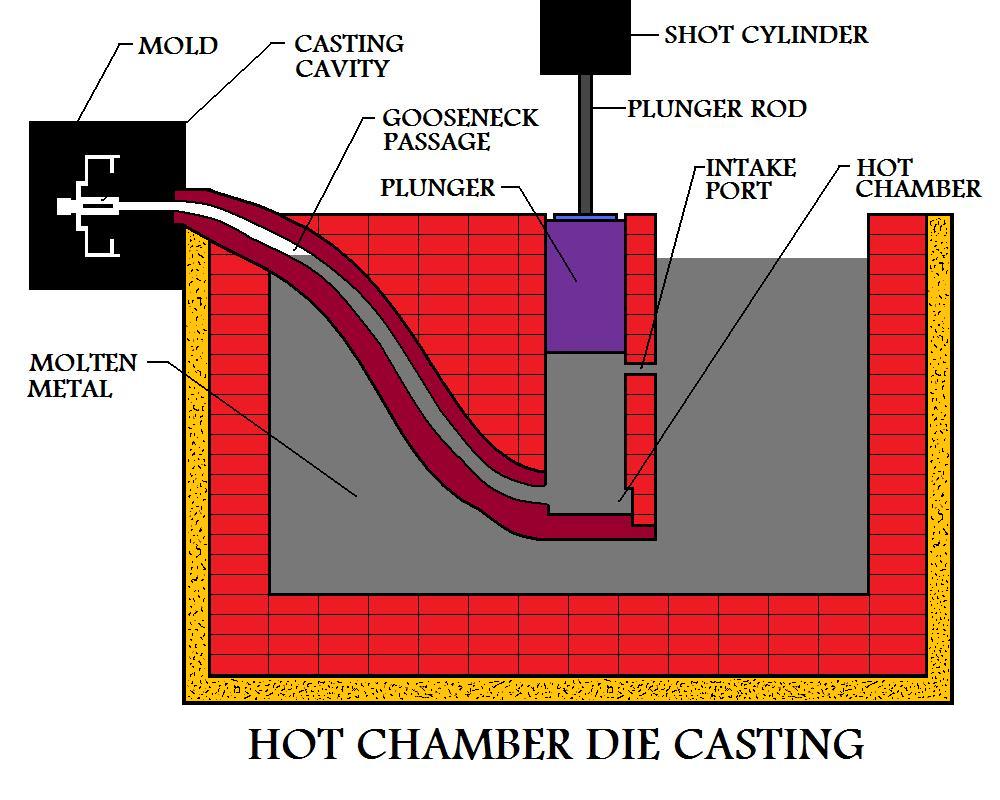

The key feature of this process is that the melting furnace is integrated into the casting machine. In this type of design, the molten metal is kept in a continuously ready-to-inject state, reducing handling time and resulting in production that is much more efficient than in other casting methods.

Summary of the Process

| Proces | Explanation |

| Melting | Metal is maintained in a furnace inbuilt as molten at about 400 -450 °C in the case of zinc alloys and 600 °C in the case of some magnesium alloys. |

| Filling the Gooseneck | In this setup, a hydraulic plunger is used to withdraw until molten metal fills the gooseneck chamber. |

| Injection | The plunger moves forward and injects metal into the die cavity at rates up to 3060 m/s. |

| Tuhnutí | The metal’s cooling and solidification take 2-10 seconds, depending on the part’s thickness. |

| Vyhazování | This is where the die opens, and the casting is removed by die ejection pins. |

| Repeat | The total cycle time is 3 to 15 seconds, enabling high production volumes. |

The Process of the Hot Chamber Die Casting

Na adrese hot-chamber die casting, the molten metal is retained in an in-built furnace mounted on the machine. The molten metal submerges a component called a gooseneck. When the plunger is retracted, an intake port supplies molten metal to the injection chamber. The plunger is then hydraulically actuated, driving the metal through the gooseneck and into the die cavity at high velocity. The injection rates may reach 30-60 meters per second, filling the cavity before the metal solidifies.

After being cast, the molten metal is pressurized and cooled. Solidification typically takes 2-10 seconds, depending on wall thickness and alloy. With the part already solid, the die is opened, and the ejector pins force the casting out. The machine thereafter shuts and initiates the subsequent cycle.

Technical Parameters and the Operating Conditions

The process is carried out within well-controlled temperature and high-pressure ranges to ensure tooling quality and safety. Slitiny zinku can be cast at temperatures between 400 and 450 °C. In contrast, magnesium alloys can be cast at temperatures closer to 600 °C. The injection pressure is typically 7-35 MPa (approximately 1,000-5,000 psi). The die temperature is maintained between 150 and 250 °C to ensure consistent metal flow and controlled cooling.

Due to the wide range of machine sizes, the clamping force typically ranges from 20 to 500 tons. Shot weights are usually less than 1 kilogram, but machines can handle up to 5 kilograms. This is one of the fastest metal-forming methods, with production rates often reaching 300-700 parts per hour due to its high cycle rate.

Applicable Material Limits and Alloys

Hot-chamber die casting applies only to alloys that do not attack iron at high temperatures. The most common are zinc alloys, including Zamak 3 and Zamak 5, which have melting points near 385 °C. It is also commonly used with magnesium alloys such as AZ91D, which melts at about 595 °C. It is also possible to process lead-tin alloys, but their industrial applications are more limited. This process cannot be applied to aluminum, which has a melting point of approximately 660 degrees Celsius, which can destroy the submerged injection elements.

Performance Benefits and Practices Limitations

- Speed is one of the greatest advantages of hot chamber die casting.

- The furnace is integrated, and the metal transfer steps are not separated, thereby reducing cycle time and energy consumption by approximately 20-30 percent compared with cold chamber systems.

- Dimensional tolerances can be as low as ±0.05 mm, and surface finishes with Ra values of 1.6-3.2 µm can be achieved.

- Tool life is also good, with loads of 500,000 or more cycles observed under well-maintained conditions.

- Nonetheless, due to continuous contact between the gooseneck, the plunger, and the molten metal, wear and tear occur.

- These parts can be changed within 50,000 to 100,000 cycles. The process is also most appropriate for small- to medium-sized components rather than large structural components.

| Parametr | Typical Range |

| Metal Temperature | 400–450°C (Zinc), up to 600°C (Magnesium) |

| Vstřikovací tlak | 7–35 MPa (1,000–5,000 psi) |

| Doba cyklu | 3–15 seconds |

| Machine Tonnage | 20–500 tons |

| Production Rate | 300–700 parts/hour |

| Teplota matrice | 150–250°C |

| Typical Part Weight | 0.02–5 kg |

Cold Chamber Die Casting: Process and Technical Observations

Cold-chamber die casting is a high-pressure metal casting process suitable for alloys with medium- to high-melting points. It is commonly used in industries such as automotive, aerospace, industrial machinery, and electronics that require strong, lightweight components with precise dimensions.

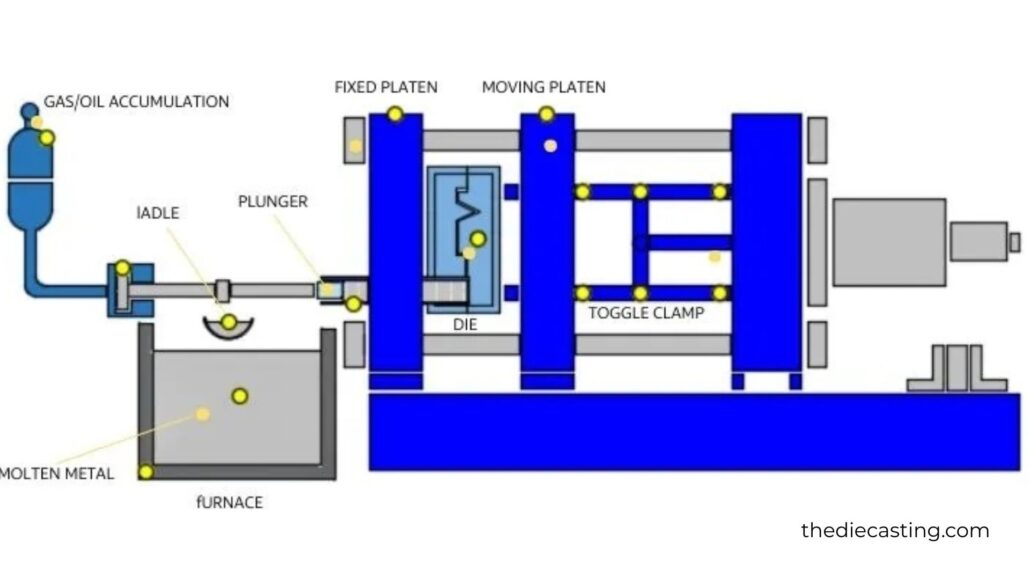

This process uses a separate furnace to melt the metal, rather than a hot-chamber die casting. Each shot is moved into the casting machine with the molten metal, making the system suitable for materials that would harm a permanently submerged injection process. This geometric distinction characterizes the operating mode, production speed, and material range of the cold-chamber process.

Process Overview

During cold-chamber die casting, the metal is melted in an external furnace at the appropriate alloy-specific temperature. The melting temperature of slitiny hliníku is generally in the range of 660- 700 °C, and copper-based alloys might be melted at temperatures exceeding 1,000 °C. After melting, a specified quantity of metal is poured into the shot sleeve of the casting machine using either a manual ladle or an automated robotic system. The shot sleeve is made out of a hardened steel cylinder that is susceptible to repeated thermal and mechanical loads.

Metal Injection and Solidification

Once molten metal is added to the shot sleeve, a hydraulic plunger advances, forcing the metal into the die cavity at high pressure. The injection pressure is very high, typically 30-150 MPa (around 4,350-21,750 psi), compared with hot-chamber casting. The metal will be poured into the mold at high speed to ensure the cavity is filled to the point of solidification.

Once the cavity is filled, pressure is applied until the metal solidifies. Solidification times also depend on part size and wall thickness, though they typically range from 5 to 20 seconds. Once the metal is solid, the die is opened with the ejector pins, forcing the casting out. Since the metal must be reloaded at each cycle, overall cycle times are longer than those for hot-chamber casting, typically 20-60 seconds.

Operating Conditions

Cold-chamber tlakové lití is used under more severe thermal and mechanical conditions. Die temperatures are typically kept between 200 and 300 °C to balance metal flow and tool life. Water or oil circulates through the die’s cooling channels to efficiently cool the die and regulate the solidification rate. Defects such as shrinkage, porosity, and warping are minimized through effective thermal management.

The plunger and shot sleeve are never fully immersed in the molten metal, unlike the components of the injection system. This reduces chemical attack and subjects them to thermal shock per cycle. These components are usually fabricated from high-grade tool steels and require regular replacement or maintenance after a series of production runs.

Machine Specifications

Die casting machines are typically larger and more powerful than hot-chamber die casting machines. The clamping forces typically range from 200 to more than 4,000 tons, enabling the production of larger and heavier parts. The weight of the shots may range from several hundred grams to more than 20 kilograms, depending on the machine’s capacity. Production rates average 100 to 300 parts per hour, with part complexity and size variation.

Suitable Alloys

The process aids metals with higher melting points that cannot be used in hot-chamber machines. A380 and ADC12 are the most popular slitiny hliníku due to their high strength-to-weight ratio and corrosion resistance.

Cold-chamber equipment is also commonly used to cast magnesium alloys, particularly for structural applications. Alloys of copper, brass, and bronze can also be worked, but they require stronger tooling due to their higher casting temperatures.

Performance Advantages

Cold-chamber die casting offers greater material flexibility and the capability to cast strong structural components. It can create parts with complex shapes, thin walls, and fine details without compromising mechanical properties. Common dimensional tolerances are of the order of ±0.1 to ±0.2 mm. The process also improves vacuum and squeeze casting, reducing porosity and enhancing structural integrity.

Process Limitations

- The primary drawbacks of cold-chamber casting are longer cycle times and higher energy consumption.

- The requirement to move molten metal per shot slows production and increases the risk of heat loss.

- There is also an increase in tooling costs due to the higher thermal and mechanical stresses that dies must withstand.

- Also, improper ladling or injection control may exacerbate air entrapment and porosity.

| Parametr | Typical Range |

| Metal Temperature | 660–700°C (Aluminum), up to 1,100°C (Copper alloys) |

| Vstřikovací tlak | 30–150 MPa (4,350–21,750 psi) |

| Doba cyklu | 20–60 seconds |

| Production Rate | 100–300 parts/hour |

| Teplota matrice | 200–300°C |

| Typical Part Weight | 0.2–20+ kg |

| Machine Tonnage | 200–4,000+ tons |

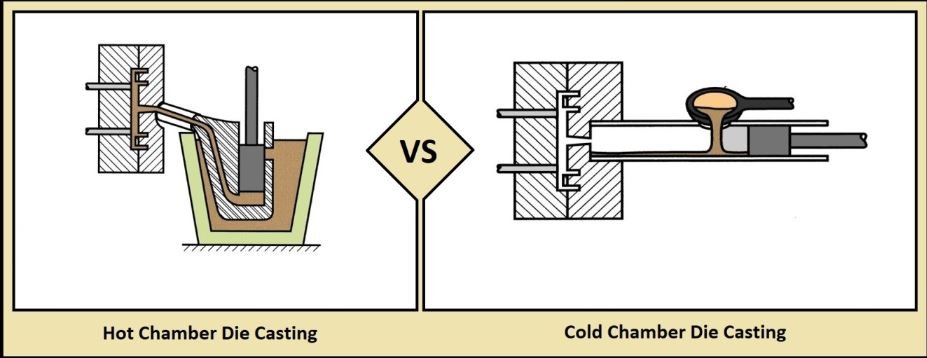

Hot Chamber Die Casting vs. Cold Chamber Die Casting

Understanding the difference between hot- and cold-chamber die casting is essential. High-pressure die casting is widely used to produce high-speed, precise metal parts. The process is categorized as hot- or cold-chamber. Although the two processes both inject molten metal into a steel die under pressure, they differ in equipment design, allowable metals, speed, cost, and usage.

| Funkce | Tlakové lití za tepla | Tlakové lití za studena |

| Furnace Location | The furnace is built into the casting machine | Metal is melted in a separate external furnace |

| Metal Handling | Molten metal is automatically drawn into the injection system | Molten metal is ladled or poured into the shot sleeve each cycle |

| Vstřikovací systém | Gooseneck mechanism submerged in molten metal | Plunger injects metal from a separate shot sleeve |

| Suitable Metals | Low melting point alloys (zinc, magnesium, lead-tin) | Higher melting point alloys (aluminum, copper, brass, bronze) |

| Melting Temperature Range | 400–450°C (Zinc), up to 600°C (Magnesium) | 660–700°C (Aluminum), up to 1,100°C (Copper alloys) |

| Vstřikovací tlak | 7–35 MPa | 30–150 MPa |

| Doba cyklu | Very short: 3–15 seconds | Longer: 20–60 seconds |

| Rychlost výroby | 300–700 parts per hour | 100–300 parts per hour |

| Machine Size | Smaller machines | Larger, heavier-duty machines |

| Upínací síla | 20–500 tons | 200–4,000+ tons |

| Typical Part Weight | 0.02–5 kg | 0.2–20+ kg |

| Part Size Capability | Best for small to medium parts | Suitable for medium to very large parts |

| Opotřebení nástrojů | Higher wear on the gooseneck and plunger due to constant contact with molten metal | Less chemical wear, but more thermal shock stress |

| Tool Life | Good, but the injection components wear faster | Dies face higher stress; maintenance costs are higher |

| Povrchová úprava | Vynikající povrchová úprava | Very good surface finish |

| Rozměrová přesnost | Very high (±0.05 mm possible) | High (±0.1 to ±0.2 mm typical) |

| Energetická účinnost | More efficient (integrated heating system) | Higher energy use due to separate melting and transfer |

| Porosity Risk | Lower due to continuous metal feed | Higher risk from ladling and air entrapment |

| Equipment Cost | Lower machine cost | Higher machine and tooling cost |

| Nejlepší pro | High-volume, small precision components | Strong structural and larger components |

| Industries | Electronics, consumer goods, hardware | Automotive, aerospace, industrial machinery |

Závěr

It is important to note that both hot-chamber and cold-chamber die casting play key roles in modern high-pressure die casting, as they support different manufacturing requirements.

Hot-chamber die casting is best suited to high-volume production of small parts, with high precision, low-melting-point alloys, high cycle times, good surface finish, and low energy consumption.

Cold-chamber die casting, conversely, is essential for metals with higher melting points, such as aluminum and copper alloys, enabling larger, stronger, more structurally demanding pieces to be produced, but at longer cycle times and higher tooling costs.

The choice of process depends on alloy type, part size, mechanical requirements, production volume, and cost, among other factors. These differences are clearly understood, enabling manufacturers to optimize quality, efficiency, and manufacturing performance.