Führende Aluminium-Druckgusshersteller in China und der Welt

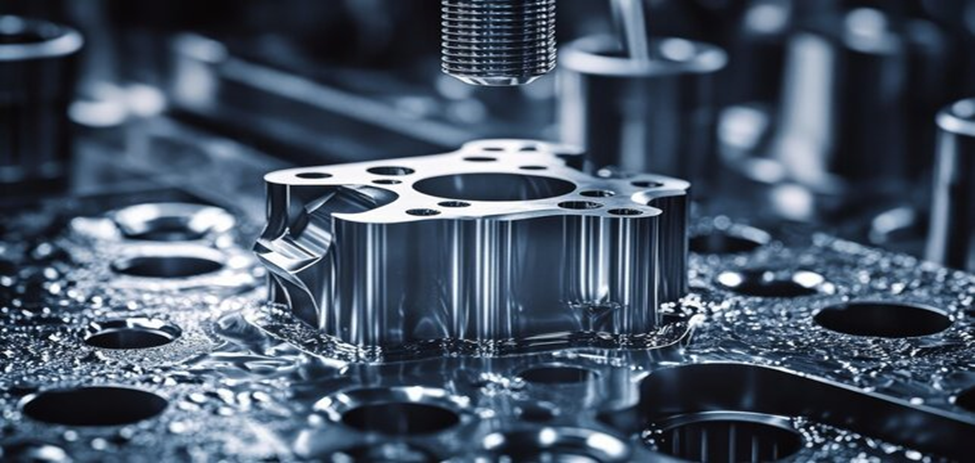

AluminiumdruckgussToday, aluminum die casting plays a central role in modern manufacturing. The aluminum die casting process is known for its precision, strength, and ability to produce complex shapes with tight tolerances, making it an integral process for industries such as automotive and aerospace, consumer goods and electronics, medical devices, etc. This very dynamic scenario continues to create demand for high-performance and cost-effective components and has led to the importance of aluminum die casting manufacturer partners becoming more critical than ever. Tooling and quality provide higher efficiency, at the same time as scalability, and have been helped along by the advancement of automation. These companies usually provide end-to-end services, from the beginning design and prototyping to mass production and surface finishing, which smoothly cover all the processes to implement according to the demands of the customer. On top of that, as the sustainability standards gain in importance, many die-casting companies take up environmentally friendly ways of working, including material recycling, adopting energy-efficient measures, and getting green certifications. The article reviews some of the best aluminum die casting manufacturers operating around the globe, such as in the US of Europe, and other countries where such a business creates an edge over others due to the value added through their innovation and customer-centric approach. These companies stand high and proud in the automotive parts manufacturing world, and could perfectly serve you if you are looking for high-volume automotive parts, precision medical components, or new ideas to solve the obscure problems in niche applications. In this blog post, we will go over their company profiles, quality commitments, certifications, and how they stand out as a fascinating inconel casting company in such a competitive world. This guide is your complete start to finding a trusted aluminium die casting manufacturer for your next project. What is Aluminum Die Casting? Machines use aluminum die casting to create sophisticated parts of precise definition by forcing molten aluminum into a die under substantial pressure to produce complex shapes. Industrial operations depend upon this method to produce durable, lightweight components having precise dimensions alongside smooth surface texture possibilities. Molten aluminum takes only a fraction of time to fill and solidify in the die cavity before automatic removal from the die and subsequent finishing operations. The automotive as well as aerospace industries, together with electronics and consumer goods sectors, adopt aluminum die casting for their material requirements because this process delivers strong parts with low weight, together with excellent resistance to corrosion and significant thermal performance. Manufacturers choose aluminum die casting because of its efficiency and automatic operation capability to create speedily and repetitively many engine housings as well as heat sinks and brackets, and enclosures. Manufacturing at high volumes becomes more economical through this process because it decreases machine workload and guarantees uniform quality levels. Sincere Tech Year of Establishment: 2005No of Employees: 100-500Business Type: It is one of China’s largest plastic injection mold makers, aluminum die casting producers, CNC machining machine service providers, and product assembly service providers. Website and Contact: Website: plasticmold.netEmail: info@plasticmold.netPhone: +86 135 30801277Address: Building 1, No. 30 Huan Zhen Rd, Shang Dong village, Qi Shi Town, Dongguan City, Guangdong province, China, 523000 Company Profile Sincere Tech is a member of the leading aluminum die casting enterprise in China, Dongguan City, Guangdong Province, founded in 2005. The company has over 100 employees, over 20 years of plastic injection molding, die casting, precision CNC machining, and full product assembly experience. Sincere Tech works with several industries, including automotive, electronics, and consumer products. The company has established itself as a leader in high precision aluminium die casting parts and complex tool solutions by using advanced technologies and the expertise of craftsmen. Due to its vertically integrated services, the company provides superior quality, timely delivery, and low-cost manufacturing. Their Quality Commitments We (Sincere Tech) take all reasonable steps within our control to provide our customers with unattended aluminium die casting parts, ddefect-freeand and of high quality, through strict process control and continuous improvement. These include state-of-the-art equipment, ISO certified processes, full inspection reports, and in-house testing. Each project of theirs meets exact specifications and receives a good focus on customer satisfaction. Sincere Tech follows the international quality standards, constantly invests in employee training and innovation to supply reliable and durable products to worldwide clients. Why Choose Sincere Tech? GC Precision Mould Year of Establishment: 1999No of Employees: 100-200+Business Type: Plastic injection molding, CNC machining, die casting of aluminium, zinc, and magnesium. Website and Contact: Website: aludiecasting.comEmail: info@aludiecasting.comPhone: +86 131 4886 5556Address: No. 30 Huan Zhen Rd, Qi Shi Town, Dongguan City, Guangdong province China, 523516 Company Profile GC Precision Mould Co., Ltd. (located in Dongguan city, Guangdong province, China) was founded in 1999, and it has a reputation as an aluminum die casting manufacturer. The company does aluminum, zinc, magnesium die casting, and CNC machining, and plastic injection molding. We are a team of more than 100 professionals in the high-performance components and assemblies for automotive, industrial equipment, telecommunications, and electronics industries. The company has a reputation for being a precision tooling machine and an inventor who is dedicated to innovation in engineering to provide a customized solution based on complex engineering project demands and efficient, reliable, and quality production at each stage. Their Quality Commitments GC Precision Mould has a strong quality management system, dedicated to the highest product quality. The company uses advanced equipment and testing methods for incoming raw materials the product delivery, and it implements very strict inspection procedures. They are certified to ISO standards and base their zero-defect manufacturing and continuous improvement focus. Clients are their clients, and their engineering and QA teams work with them closely to fend off all of their technical specifications and provide them with really comprehensive quality documentation, which is fully traceable through to the end of the production cycle. Why Choose GC Precision Mould? CNM Tech Year of Establishment: 20+ yearsNo of Employees: 100-400Business Type: Specializes in die casting, CNC machining, and product assembly Website and Contact: