Soudage TIG de l'aluminium : Guide technique complet

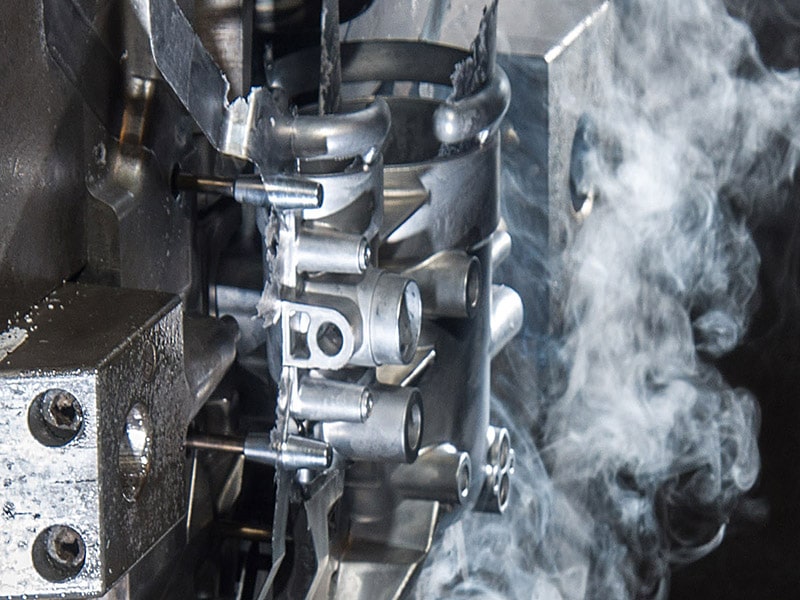

fonte d'aluminiumTIG Welding Aluminum is widely regarded as one of the most technically demanding processes in the field of welding. When working with aluminium, the metal that is characterised by its light weight, corrosion resistance, and high conductivity, a set of unprecedented problems emerges, which distinguishes it so much in terms of steel or stainless steel. Poor handling of aluminum can cause the natural oxide layer to provide a weak, porous, or otherwise structurally undesirable weld due to its natural oxide level, low melting point and its ability to absorb hydrogen gas. Thus, the TIG (Tungsten Inert Gas) process, or the Gas Tungsten Arc Welding (GTAW) process, is the process of choice by the industry to use in instances when precision, aesthetics, and weld integrity are the main factors. These will cover the behaviour of materials, selection of equipment, choice of shielding gas, joint preparation and troubleshooting methods, although much emphasis will be placed on quality control and repeatability. Additionally, the article will detail how to correctly select and operate an aluminum tig welder, manage various types of aluminum welding parts, and produce consistent, defect-free joints when attempting to weld aluminium TIG. By the end, the reader will have a thorough knowledge of how to create a good, clean, structurally good-looking tig-welded aluminium assembly as per the industry standard in the aerospace, automotive industry, marine industry, as well as the manufacturing industry. This article discusses the science, methods as well and practical aspects of TIG welding on aluminium. It is meant to be used by experts and technically trained people who want to extend their knowledge about the welding of aluminium in high-performance or industrial processes. What is TIG Welding Aluminum? TIG Welding Aluminum refers to the process of joining aluminium components using Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW). Here, an electric arc is generated by a non-consumable tungsten electrode and aluminium base metal and a filler rod are melted in a protective cover of inert gas, usually argon. Since aluminium has high thermal conductivity, low melting point and a high melting oxide layer, welding aluminium has unique colouring, and drying must be done carefully. TIG welding has a situated control of heat input and weld puddle, which means it is perfect in thin materials, advanced assemblies and other high-performance applications. The aerospace, automotive, and marine industries, among others, use TIG welding to manufacture resistant, non-corrosive, and neat-looking welding video. Successful “TIG Welding Aluminum” requires skilled technique, proper equipment, and careful surface preparation to ensure weld integrity and strength. Why Aluminum TIG Welding? Gas Tungsten Arc Welding (GTAW), which is also known as Tungsten Inert Gas (TIG), is the ideal technique to use where precision, control and a fine look are requisite. It offers unparalleled control in the amount of input heat so that welders have the opportunity to control the fluidity of the weld pool of the aluminum. The TIG welding, when utilized with aluminum is quite convenient mainly because: Welding aluminum involves a better understanding of its physical and chemical properties and which are much different compared to other widely used metals. Below are the key challenges associated with TIG Welding Aluminum. 1. Very High Thermal Conductivity Aluminum carries heat 5 times than steel. This means that heat dissipates quickly from the weld zone, requiring higher amperage when attempting to weld aluminium TIG, especially with thick materials. When not done best can end up in gap fusion or irregular weld penetration. 2. Oxide Layer Problems When aluminum surfaces are exposed to air, a layer of oxide (reliably adherent) forms instantly, and it is thin. This layer is melted at approximately 2050 °C, which is well above the base metal melting point of aluminium, which is 660 °C. TIG welding, when AC mode is used, assists in breaking this layer, but it is also important that pre-cleaning is done to produce high-quality TIG-welded aluminium. 3. Hydrogen Porosity Susceptibility Hydrogen readily absorbs in molten aluminum, and this can create porosity or cause cracks during cooling. Oil, moisture, or dirty filler rods acted as a source of contaminants that caused the hydrogen to get into the weld pool. Proper cleaning and using dry filler rods are essential to avoid defects in aluminum welding parts. Technical Summary Table for TIG Welding Aluminum Here is a comprehensive technical table summarising the key aspects of TIG Welding Aluminum, including welding parameters, joint types, common defects, and how to manage them. In this table, you combine the ideas of your article, and it is original and highly technical. Category Technical Detail Recommendations / Parameters Base Material 1xxx to 6xxx aluminum alloys are most commonly TIG welded Clean all surfaces before welding; avoid 7xxx for high-crack sensitivity Main Process TIG Welding Aluminum using alternating current (AC) Use an inverter TIG with AC balance, high-frequency start, and stable arc control Primary Keyword Weld aluminum tig Use appropriate AC balance and amperage; optimize puddle control and filler deposition Electrode Type 2% Lanthanated or Ceriated Tungsten (1/16″, 3/32″, or 1/8″) Sharpen to a truncated point or ball tip (for AC), depending on application Shielding Gas High-purity Argon (99.99%) Flow rate: 15–20 CFH; add Helium for thicker materials or deeper penetration Filler Rods ER4043, ER5356 Match filler to base alloy and application (ER5356 for strength, ER4043 for crack resistance) Joint Types Butt, Lap, T, Corner Design with small gaps (~1/16”) and allow for thermal expansion Weld Preparation Degrease + stainless steel wire brush No touching after cleaning; remove the oxide layer before welding Torch Technique Short arc length (<1/8”), 10–15° travel angle Keep filler outside the arc cone to prevent oxidation Amperage Settings 1 amp per 0.001” thickness baseline 60–130 amps for most thin-to-mid aluminium applications AC Frequency Controls the arc focus 120–200 Hz for clean, narrow arc on thin aluminum welding parts AC Balance 70% EN / 30% EP typical Adjust toward more EN for deeper penetration; more EP for cleaning oxide Tip: Make sure to calibrate your aluminum tig welder properly