Miért melegszik jobban és tart tovább az öntött alumínium sütőedény?

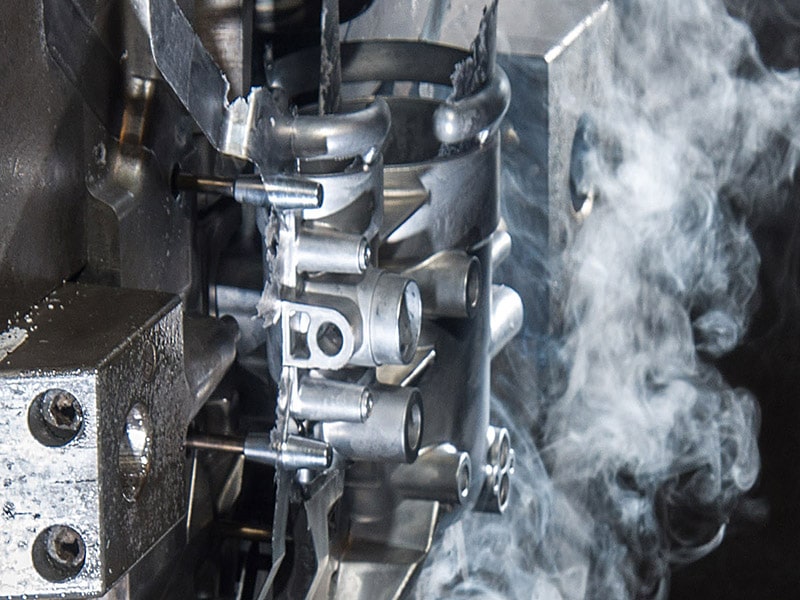

alumínium öntvényA könnyű súly, az erő és a sűrű hőelosztás jellemzői miatt az öntött alumínium sütőedények egyre népszerűbbek a pékek körében, különösen azoknál, akik első osztályú és tartós termékeket szeretnének. Az öntött alumínium a teljesítmény és a könnyed használat megfelelő egyensúlyát jelenti, ellentétben más hagyományos sütőedényekkel, mint például az öntöttvas és a rozsdamentes acél. Az olvasztott alumíniumformákban öntik, és egy erős, tartós és kényelmes használatú, még egy amatőr pék számára is. Az öntött alumínium kiváló hővezető képességgel rendelkezik, ami garantálja az ehető ételek, különösen a pékáruk egyenletes sütését, hogy megakadályozza a túlsütést és a nem egyenletes barnulást. Az öntött alumínium sütőedények előnyei közül a nagyszerű a hőmérséklet állandósága, ami a kifogástalan sütés kulcsfontosságú eleme. Gyorsabban felmelegszik, mint mások; ezért hamarabb elkészül, és könnyű súlya miatt könnyebb kezelni a konyhában. Az öntött alumínium sütőedények legtöbb darabja tapadásmentes bevonattal is rendelkezik, ami még könnyebbé teszi az ételek kioldódását és a sütés utáni takarítást. Az öntött alumínium sütőedények az üveghez és a rozsdamentes acélhoz képest nagyobb tartósságot és szilárdságot is biztosítanak, ellenállva a vetemedésnek. Bár az öntöttvas hőmegtartás tekintetében páratlan, az öntött alumínium közel ugyanolyan mértékű hőeloszlással rendelkezik, de kisebb súly mellett. Az öntött alumínium sütőedények nagy kedvencei a profi pékek és az otthon főző emberek körében is, mindezt a hatékony és tartós sütőeszközök iránti vágy miatt. Mi az öntött alumínium sütőedény? A sütőedények öntési módszere, az öntött alumínium alapján, ez a már előkészített formákba öntött olvadt alumínium felhasználásával készül, sütőformák, tortaformák, piteformák és különböző más sütési szükségletek előállításához. Az eljárás révén a sütőedények erősek, de könnyűek, így a sütés és a tálalás során a sütőedények hatékonyan kezelhetők. Az úgynevezett öntött alumínium sütőedények legjobb tulajdonságai közé tartozik, hogy egyenletes hővezető tulajdonságokkal rendelkeznek. Ez azt jelenti, hogy a sütött termékek, például a sütemények, a kekszek és a kenyerek jól átsülnek, nincsenek forró területek vagy megégett oldalak. További előnyökkel jár a fém gyors felmelegedése és kihűlése, ami viszont némi időt takarít meg a sütés során, és ez az elfoglalt pékek számára előnyös. Az anyag olyan erős, és nem rozsdásodik vagy korrodálódik könnyen, ezért ez hosszabb ideig tartana a konyhában. Ezenkívül nem jár sok karbantartással és kopással, szemben néhány más anyaggal, amelyek idővel elhasználódnak, mivel sok használat lesz. Az öntött alumínium sütőedények előnyei 1. Tartósság A sütőedények öntött alumíniumból készülnek, így hosszú ideig tartanak. Az alumínium szinte immunis a kopással szemben, azaz a gyakori használat mellett sem repedezik vagy vetemedik. Sütőedényei akkor is tartósak lesznek, ha naponta vagy rendszertelenül használja őket. 2. Egyenletes hőeloszlás Az öntött alumínium sütőedény kifejezés legmeglepőbb tulajdonságai közé tartozik, hogy a hőt az egész felületen átadja. Ez csökkenti az inkonzisztens sütést, mivel a végtermék textúrája és színe szabályos. Ideális azon pékek körében, akik arra törekszenek, hogy egyenletes teljesítményt hozzanak. 3. Könnyű súly Az öntött alumínium sütőedények sokkal könnyebbek más, terjedelmesebb anyagokhoz, például az öntöttvashoz képest, ezért könnyen kezelhetőek. A nagy teherbírású sütőlemezek vagy tortaformák nagyon könnyen felemelhetők, áthelyezhetők és tárolhatók, és ez ideális minden pék számára, akár profi, akár nem. 4. Tapadásmentes tulajdonságok Az “öntött alumínium sütőedények” legtöbb terméke szintén tapadásmentes bevonattal van ellátva, ami még kényelmesebbé teszi a használatukat. Ennek a tulajdonságnak a jelenléte megkönnyíti a sütemények elkészítését; ezért kevesebb olajat vagy spray-t kell használni. A takarítást is könnyebbé teszi, mivel kevés maradvány marad a sütés után. 5. Korrózióállóság A legtöbb fémmel ellentétben az öntött alumínium sütőedények nem rozsdásodnak könnyen. Nem korrodál, ezért ideális anyag, ha valaki hosszú távon szeretné használni. Ez a szempont különösen olyan területeken jön jól, ahol különböző mértékű páratartalom és hőmérséklet uralkodik. Öntött alumínium sütőedények: Az öntött alumínium sütőedények gyártása gondos és nagyon következetes, a minőség és a teljesítmény fenntartása érdekében kidolgozott gyártást jelent. A legfontosabbak a következők: 1. Szerszámöntés A folyamat első szakasza a szerszámöntés lesz, azaz az olvadt alumíniumot nagy nyomáson acélformákba fecskendezik. Ez a technika biztosítja, hogy a sütőedényt nagyon pontosan és következetesen formázzák és öntik. Az olvadt fém a forma összes üregének terébe bejut, ami a különböző sütőedények, köztük a tortaformák, muffinformák és kenyérsütőformák összetett formáit és apró részleteit eredményezi. 1. Megszilárdulás és hűtés Miután az olvadt alumíniumot a formába fecskendezték, hagyják kihűlni és megkeményedni. A hűtést is úgy szabályozzák, hogy az alumíniumnak a kívánt tulajdonságai, például szilárdsága és hőállósága meglegyen. Ahogy a sütőforma megszilárdul, lassan felveszi végleges formáját, és ez általában csak néhány perctől néhány óráig tart, attól függően, hogy milyen vastag és kidolgozott a forma. 2. Kiemelés és ellenőrzés Miután az alumíniumdarabok teljesen kihűltek, kivesszük őket, és kinyitjuk a formát, ezzel kiszabadítva az öntött alumínium sütőedényt. A második eljárás a hiba teljes ellenőrzéséből áll, például a légbuborékok és repedések jelenlétéből vagy az érdességből. A hibás sütőedényeket vagy kijavítják, vagy kidobják, és csak a jó minőségű sütőedények jutnak tovább a gyártási folyamatba. 3. Felületkikészítés Az ellenőrzés befejezése után a sütőedényeket felületkikészítő kezelésekkel látják el. Ezek olyan dolgokat foglalhatnak magukban, mint az eloxálás, a felület érdesebbé tétele, hogy ellenálljon a korróziónak és a kopásnak, vagy tapadásmentes anyaggal való bevonása, hogy könnyebb legyen a sütött ételek kiszabadítása és a sütés utáni tisztítás. A felületkezelés a