Cosa sono le pentole in alluminio fuso?

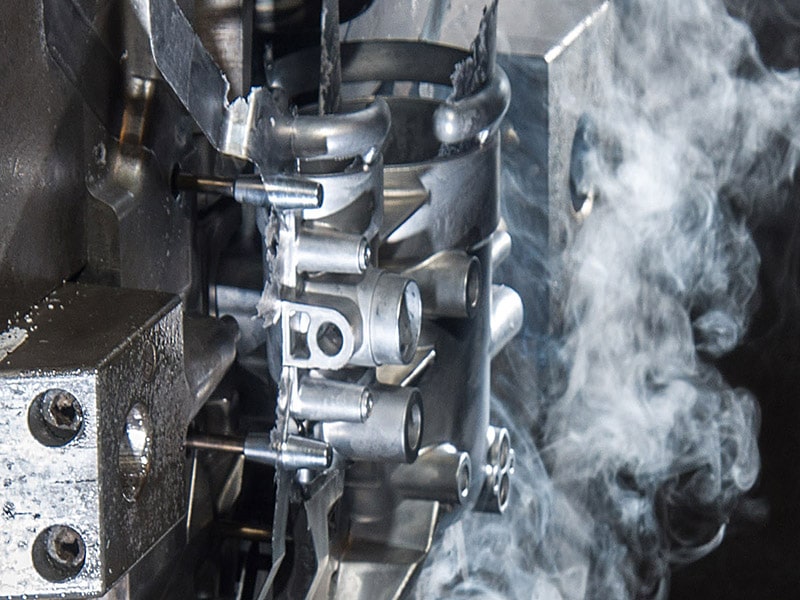

AlluminioThe cast aluminum cookware is often used by home cooks and professional chefs and is known and appreciated because it is durable and lightweight at the same time, with a high distribution of heat. Cast aluminum cookware is manufactured by pouring molten aluminum into moldings; the main aim of such cookware is to ensure that it gives even heating, it should not warp, and it should be able to last a long time. Its application has made it an all-purpose element in the kitchen since it is applicable in most of the cooking methods, such as frying and sauteing, baking and roasting.Among the most notable benefits of cast aluminum cookware is the fact that it warms up fast and equally. Cast aluminum cookware can also be said to be thicker than its thinner counterparts, such as the stamped aluminum, which makes them have good thickness to maintain a homogenous cooking temperature. It is also usually manufactured to have non-stick layers, and thus also lowers the amount of oil used, and cleaning becomes easier.Over time, cast aluminum cookware manufacturers have been advancing and making it exceptional through new materials, environmentally friendly coatings and other non-stick technologies. These developments also make it even more popular and provide its customers with a more efficient, healthier, and more sustainable process of cooking. You invite your friends over, you are in the process of putting together a simple meal or a complicated one; cast aluminum cookware comes in handy to do the job, this is because its performance is dependable and works in tandem with the demands of a modern kitchen. Understanding Cast Aluminum Cookware Cast aluminum cookware refers to pots, pans and skillets, plus the other kitchen equipment manufactured at the local level by pouring molten aluminum into moulds. The casting of the cookware makes it quite robust in structure, which therefore makes it considerably stronger as compared to ordinary aluminum. In comparison to stamped aluminum (prepared on thin sheets), cast aluminum cookware is far thicker, hence offering more heat retention and distribution. The warp factor as time passes is one of the primary factors people love using cast aluminum cookware, as the problem is prevalent with thin material. This also assists in even cooking temperature, so that cooking of different dishes is likely to give more similar results. Die-cast aluminum cookware Die-cast aluminum cookware follows the use of aluminum that undergoes the die-casting procedure. It is done through the pouring of molten and pressurised aluminium into a cavity. This way, the shape and the thickness of the cookware can be controlled accurately. The die-cast aluminum cookware is usually more sophisticated as compared to the regular cast aluminum since it has a refined texture and smooth surface.The advantage of the die-cast aluminum cookware is that it is not as heavy as some of the other materials, such as cast iron. This is more convenient when cooking and cleaning up, thus Ideal in cooking choice, especially when one requires cookware that is of good quality but not heavy.The other attribute of die-cast aluminum cookware is that it is versatile. It applies to a large number of procedures such as frying, baking and simmering. It also usually has a non-stick coating added to it, which contributes to it being easy to use and clean. Nevertheless, one should keep in mind that the non-stick coating may wear down over time, unless it is maintained carefully. What is Cookware? Cookware can also be defined as the different kinds of pots, pans and other cooking utensils that are employed in the preparation of food. Such objects are frequently produced with such materials as stainless steel, aluminum, cast iron, ceramic, non-stick covered items, and copper. The primary aim of cookware is to assist in preparing and cooking food materials by using different methods, i.e., boiling, frying, sauteing, baking, or grilling. The kind of cookware: 1. Cooking Pots and Pans: Cooking is done using the two most basic cooking pots. They are of different shapes and sizes, such as frying pans, saucepans, stockpots and saute pans.2. Baking Dishes: This category will be trays, pie dishes, and cake pans, which are only used to bake.3. Speciality Cookware: These are woks, grills, Dutch ovens and pressure cookers. Materials Used in Cookware The process of manufacturing cast aluminum cookware Manufacturing of cast aluminum cookware consists of the following steps, which include melting of aluminium, molding, finishing and coating. The procedure of manufacturing cast aluminum cookware is described in as many steps as possible below: 1. Melting the Aluminum The aluminum metal has to be melted to prepare it, and that is the first stage of its production of cast aluminum cookware. Sand, metal, or ceramics are typical materials that make up this kind of mould. The temperature regulation is done with accuracy to ensure that the aluminum reaches the correct viscosity to be cast with. 2. Preparing the Mould After the aluminum has been melted, a form is initiated to shape it into the preferred form of cookware. Aluminum is poured in the form of Aluminum. Where cast aluminum itself is used, the moulds are often sandcast, and they are specifically designed to make an individual piece of cookware (a frying pan, a pot, a skillet, etc.).Once the mould is prepared, the molten aluminum is supposed to be poured into the mould cavity. This depression takes the form of the cookware to be produced. Metal Moulds: There are metal moulds that can be reused, which are reused and are able to hold the heat at greater temperatures. 3. Pouring the Molten Aluminum Once the aluminum has been poured into the mould, it is cooled down. The liquid metal is added to all the areas of the mould, and it assumes the form of the cookware. This pouring process should be accurate so that the cookware is also shaped properly and flawlessly.At this phase, the pouring of the aluminum into the mould is done either manually or automatically (depending on the magnitude of the