ISO & IATF 16949 quality certified die casting manufacturer in China, Chinese cost but Europe standard, All in one services from Magnesium die casting process, Post machining, surface finish, inspection, packing and delivery.

What is Magnesium Die Casting ?

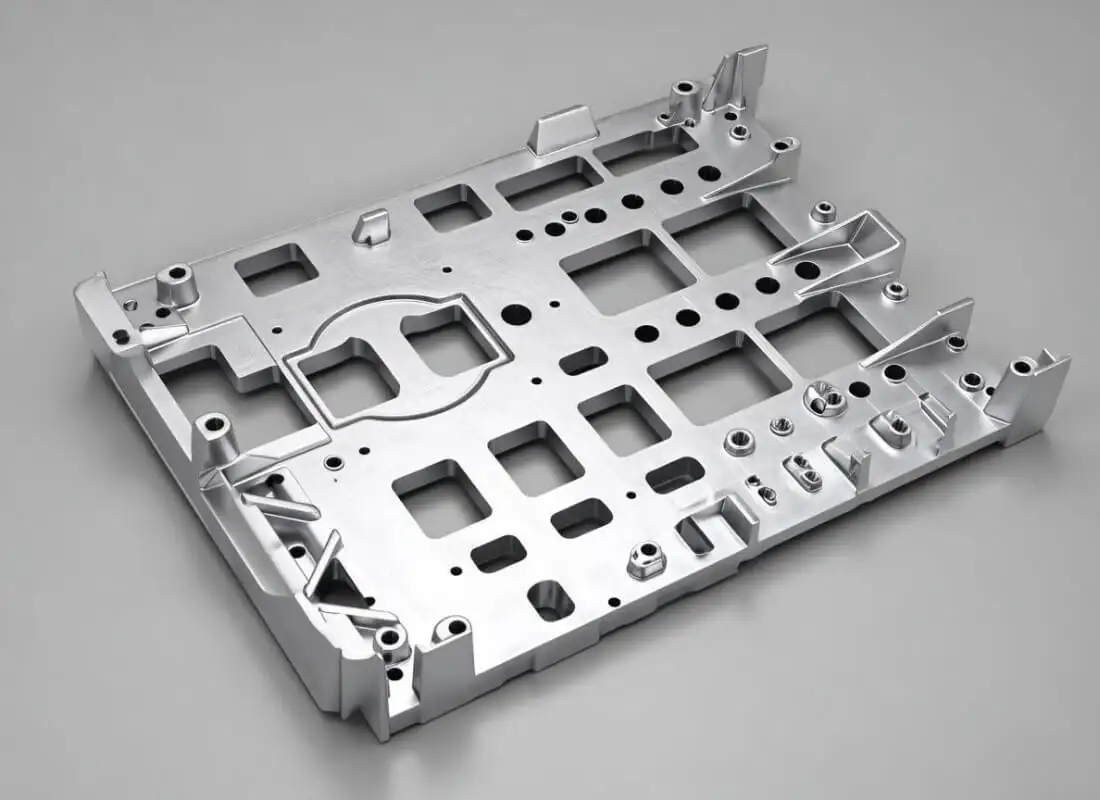

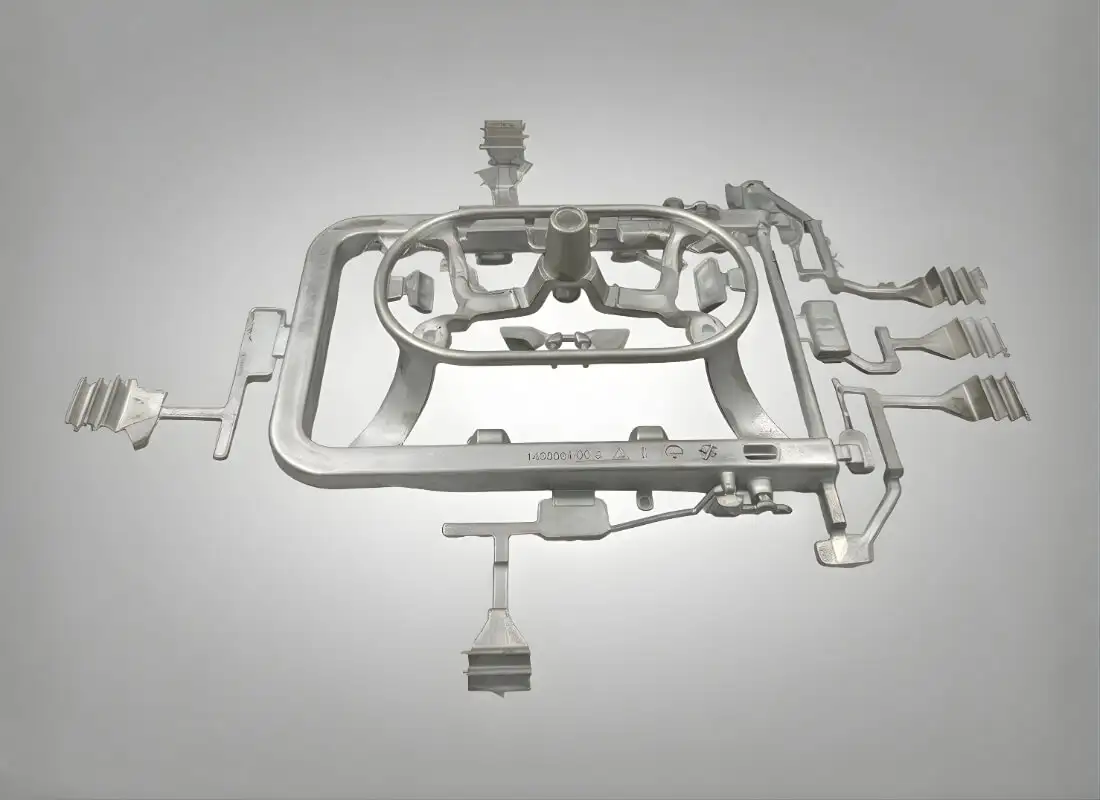

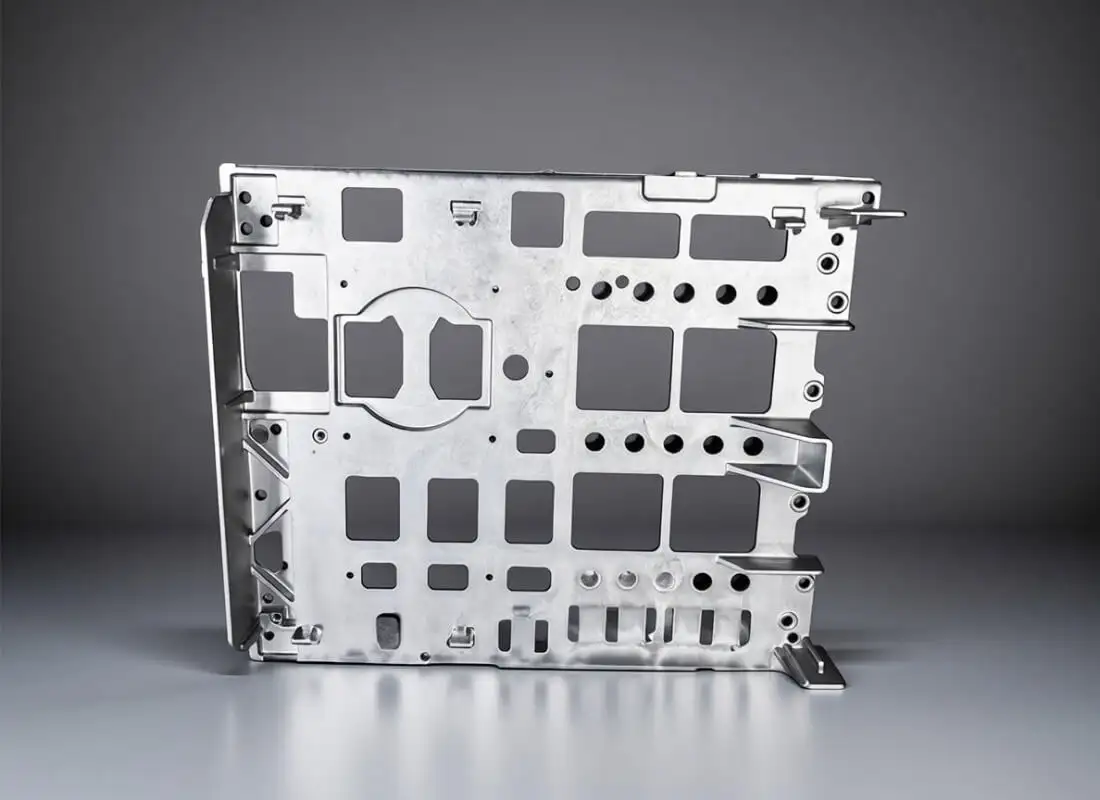

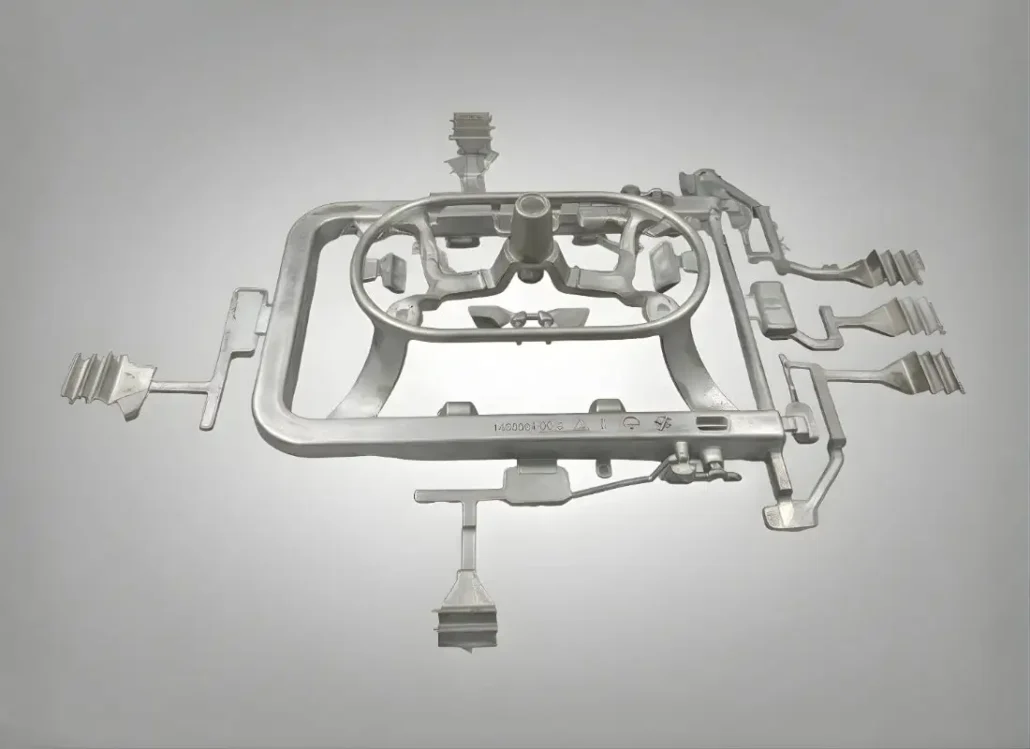

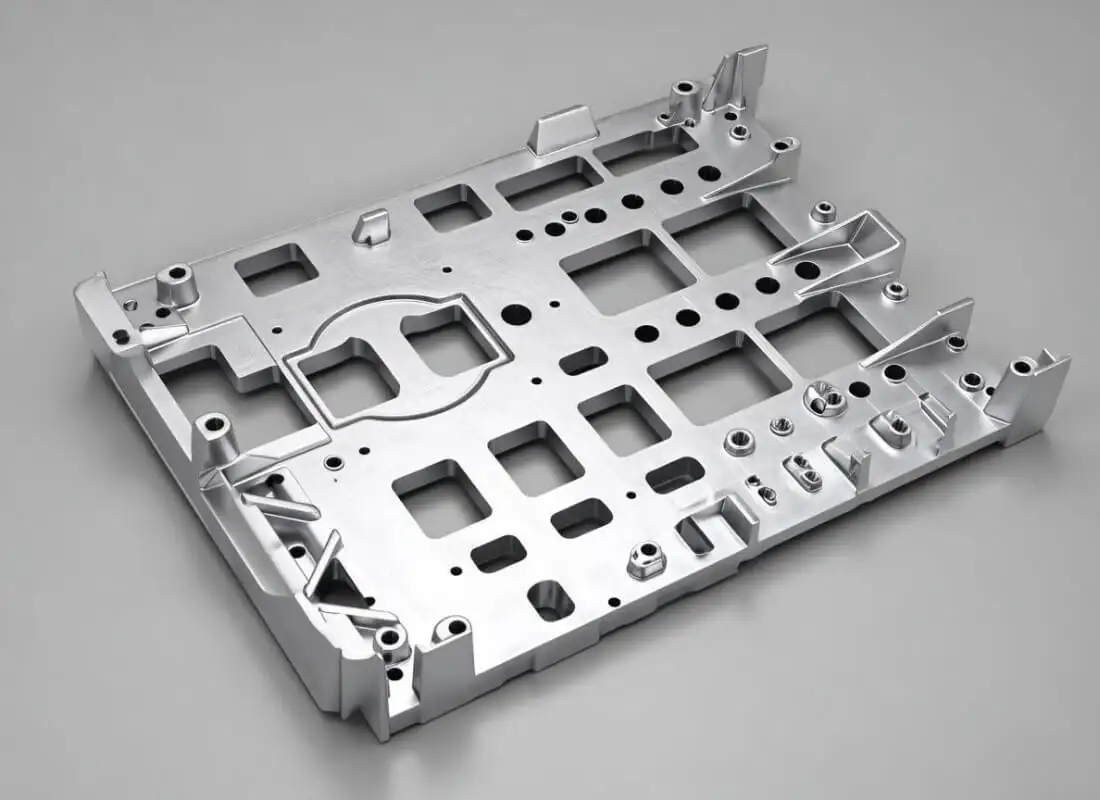

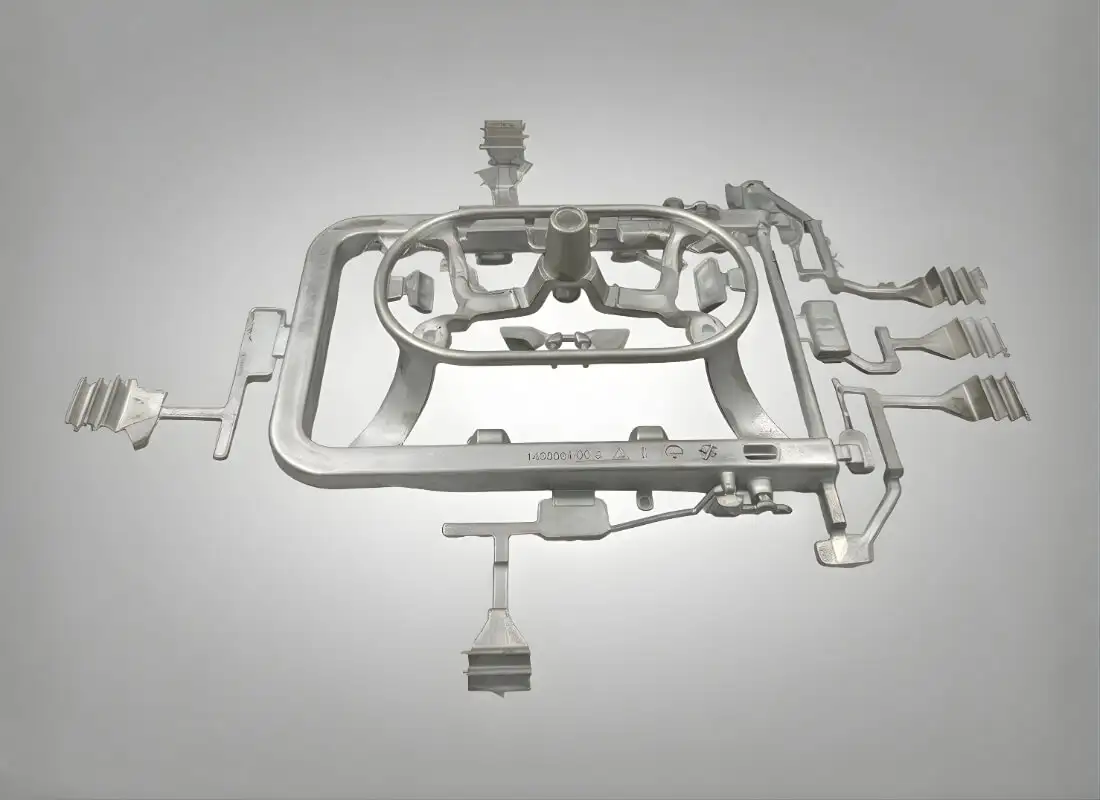

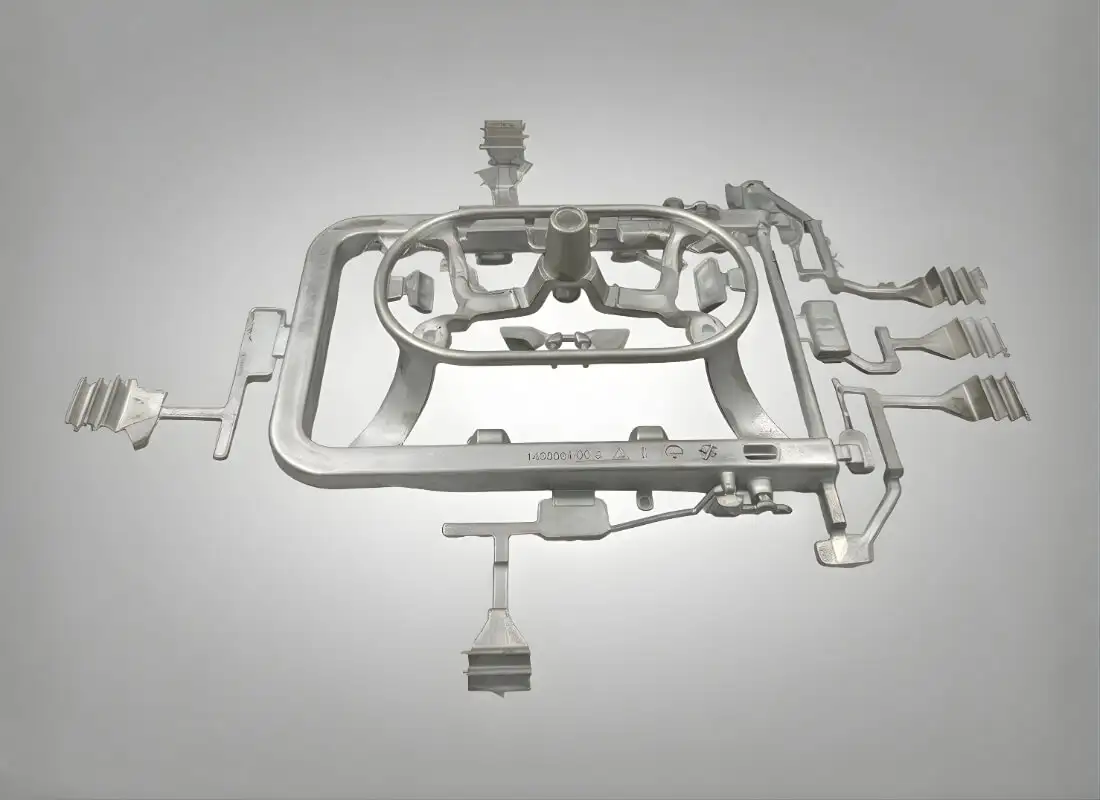

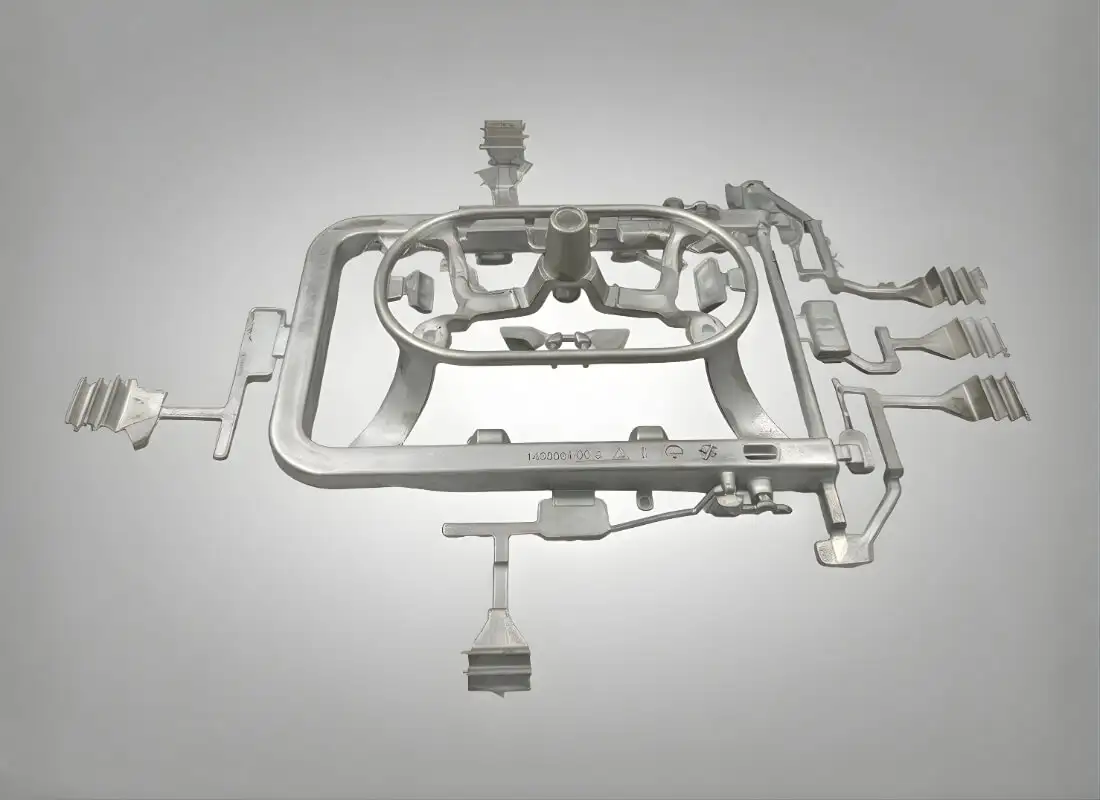

Magnesium die casting is a process in which the molten metal is forced to press under high pressure into the mould cavity using magnesium alloys. High pressure Die casting is one of the best technique widely used to create inexpensive metal parts for a variety of applications, especially magnesium casting products. The metal hardens to get the desired shape.

Magnesium is the lightest of all structural metals and is widely used in applications that require high-performance properties. In addition, the magnesium mass is almost equal to many plastics and has many advantages over plastics, including excellent toughness and corrosion resistance. The magnesium parts can be poured in a clean form and have a high ratio of strength to weight. Magnesium die casting can also be used in high-temperature applications

Magnesium is lightweight and has a strong structure for some casting components. Replacing magnesium components instead of heavy aluminium die casting products can help reduce fuel costs in vehicles where car manufacturers develop new techniques to use the unique properties of magnesium.

Magnesium die casting manufacturing in China

Magnesium is an excellent choice of die casting to distinguish between durable and durable products, providing a perfect combination of lightness, hardness and corrosion resistance to various casting applications. From concept to completion, with. Magnesium is also 100% recyclable, making it an attractive option when looking at the environment. Once the casting tool or die casting component reaches the end of its life, it can be easily recycled to serve a different purpose, thus saving costs and environmental impacts.

Advantages of magnesium die casting

There are numerous advantages to die casting part made in magnesium. Magnesium is not only the lightest in all structured materials, but it has excellent rigidity and strong weighting factors. In addition, it has distinct security properties, ideally suited for connectors and electrical buildings.

It has a low melting point

The low melting point makes magnesium much faster and energy efficient to melt without sacrificing the strength of the metal. Low temperature also provides faster cooling. The melting of magnesium is slightly higher than the usual aluminium alloy, making it very compatible with casting projects.

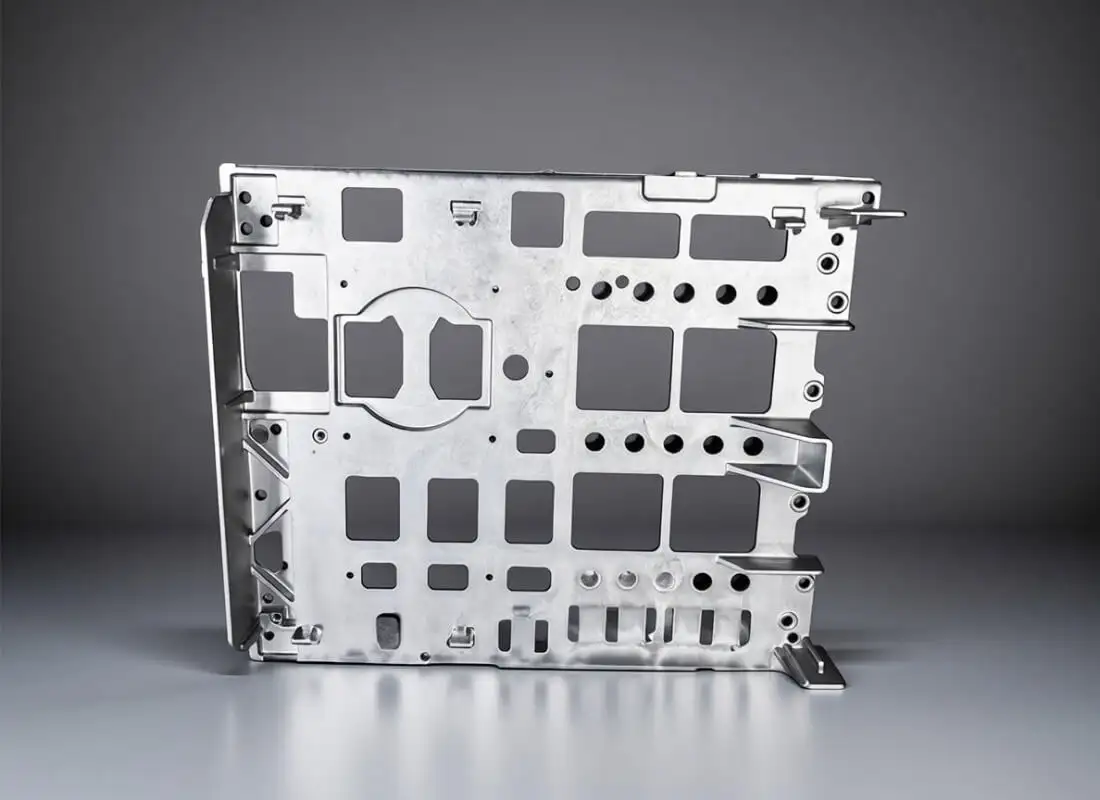

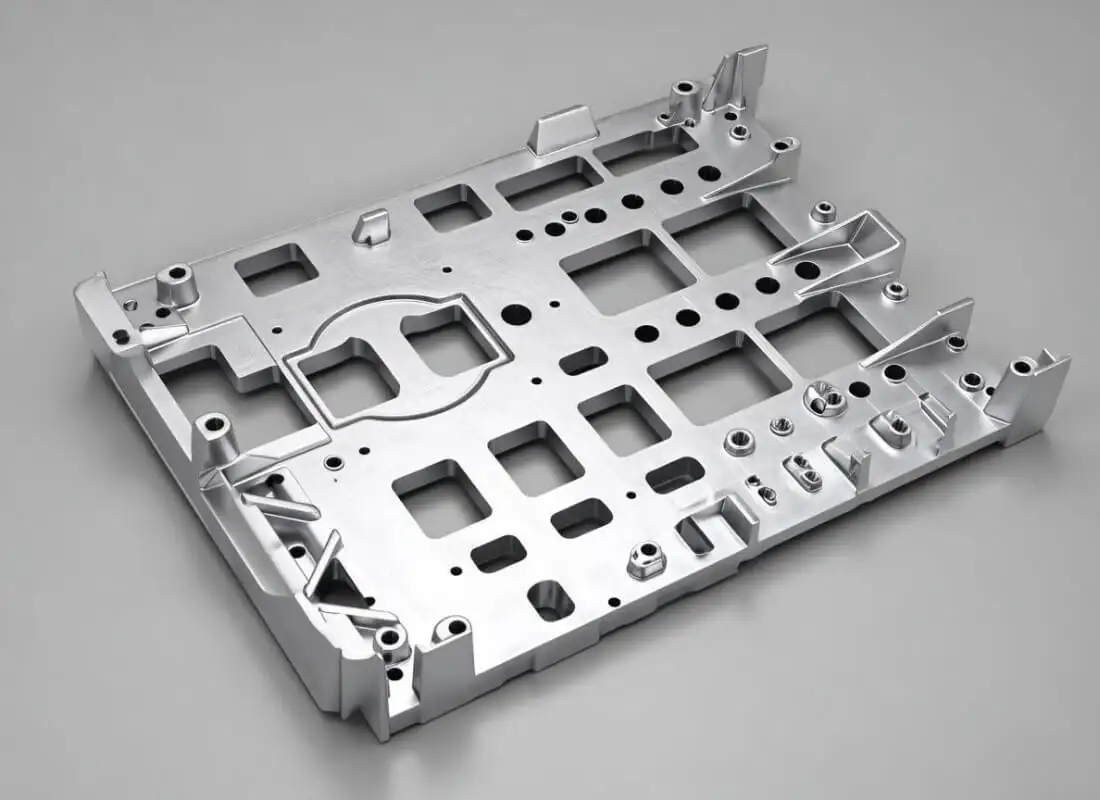

High dimensional accuracy and stability

The best strength/weight ratio for magnesium metal commonly used. Excellent dimensional stability, as well as high impact resistance and dent. The exceptional hydration capacity and low rigidity make it ideal for parts that undergo frequent and sudden changes in direction. High purity alloys can provide the latest best resistance to corrosion of carbon, steel and some aluminium alloys.

High electrical and thermal conductivity

Low heat content means that it requires less energy to reach the casting temperature, and castings are cooled more quickly so that the cycle time is faster. Low temperatures and low intimacy of iron reduce the impact of heat fatigue and corrosion on moulds so that they last longer.

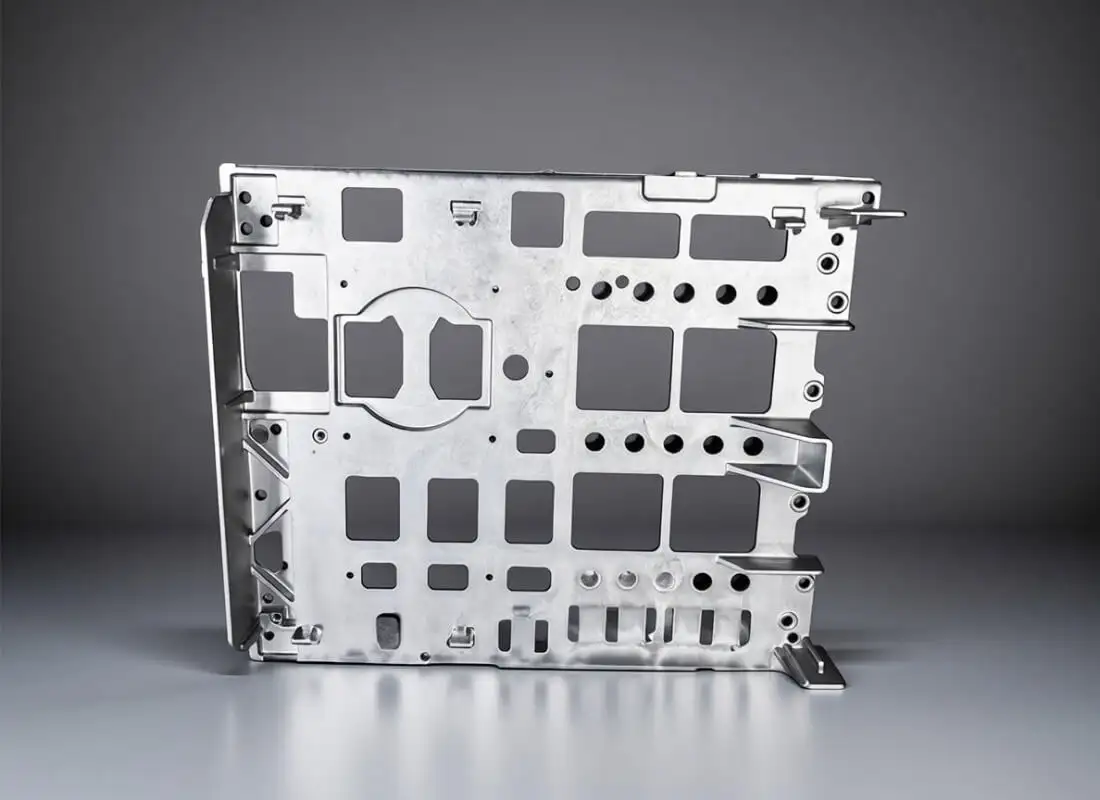

Exceptional thin wall capability

Thin-walled die casting means systems can be manufactured as a single piece, rather than assembled from several components. This simplifies design, reduces assembly costs, improves reliability, reduces the cost of tools and reduces joints, clamps, and welds.

disadvantages of magnesium die casting

Special treatment methods and coatings are essential in determining the application of magnesium casting this is because Magnesium contains impurities, which means that the metal must be cleaned before pouring to remove impurities from the finished product.

Magnesium consumes a large amount of heat in solubility in preparation for die casting, The casting temperature, magnesium provides a much shorter lifespan than other alloys, which can increase production costs.

Since magnesium is easy to get fired, the magnesium dust of accessories in the workshop sometimes leads to initial blasting and fired, so there must be complete ventilation equipment in the processing workshop, including fine equipment such as dust collectors. Control the ignition source, fire prevention measures is the number one important thing when working with magnesium alloys.

CNM TECH has rich experience in producing magnesium alloy die casting parts, we have fully controlled safety systems to produce magnesium die casting parts, contact us to get a price for your project.

Magnesium die casting

Here are the properties of magnesium die casting.

Design and Engineering

The process starts by undertaking consultations with our clients to understand them. There is professional software, which our design team utilizes to generate detailed sketches of the mold. Whether a complex high pressure die casting tooling design or a straightforward aluminum die casting mold, we ensure the design is optimized for efficiency and durability.

General Die Casting Tooling

General die casting tooling includes molds and related tools for applications that do not require the extreme pressures of high-pressure systems. These tools are mainly applied in small-scale machining or when dealing with part of simple shapes. As an experienced die casting tooling manufacturer, we understand the nuances of high-pressure and general tooling, ensuring our clients receive solutions that match their specific requirements.

The Process of Die Casting Mold Creation

The creation of a die casting mold is a highly technical process that involves several stages, each demanding meticulous attention to detail. At TheDieCasting.com, we follow a structured approach to ensure the highest quality molds:

Material Selection

Selecting an appropriate material is an important criterion for the container’s efficiency. We then precisely choose materials that can endure the intrinsic pressure and temperature of the operation stage without compromising the structure. This means that every mold that is produced here offers you enduring reliability.

Sustainability in Die Casting Mold Production

TheDieCasting.com follows sustainable business practices as a foundation for the company. We aim to reduce waste and energy use in making molds as much as is practically possible. For instance, our aluminum die-casting molds are designed for efficiency, ensuring optimal material usage and reducing environmental impact.

FAQs

What is the difference between aluminum die-casting and magnesium die-casting

Aluminum die-casting is preferred for its high strength, superior corrosion resistance, and lower material cost, commonly using cold-chamber machines for structural, heat-resistant parts. Magnesium die-casting is 33% lighter, offers faster production cycles due to lower melting points, and is ideal for lightweight, high-precision applications like electronics, but typically has higher material costs and poorer corrosion resistance.

Key Differences at a Glance

- Weight & Density: Magnesium is significantly lighter (approx. 1.74 g/cm³) than aluminum (approx. 2.70 g/cm³), providing superior weight reduction.

- Strength-to-Weight Ratio: Magnesium offers a better strength-to-weight ratio, making it ideal for lightweight structural components.

- Corrosion Resistance: Aluminum exhibits superior corrosion resistance; magnesium is more susceptible to corrosion and often requires special coatings.

- Production Process: Magnesium is usually cast in hot-chamber machines (faster cycles), while aluminum requires cold-chamber machines.

- Temperature Resistance: Aluminum retains its strength at higher temperatures better than magnesium.

- Cost: Generally, aluminum die-casting is more cost-effective regarding raw materials.

When to choose magnesium die-casting

Choose magnesium die-casting when maximum weight reduction is critical without sacrificing structural strength, such as in automotive, aerospace, or portable electronics (33% lighter than aluminum, 75% lighter than steel). It is ideal for complex, thin-walled, and rigid parts needing excellent EMI shielding, high vibration damping, and fast production cycles.

When to Choose Magnesium Die-Casting:

- Extreme Lightweighting: When components must be lightweight but strong, making it ideal for automotive, aerospace, and consumer electronics.

- Complex, Thin-Walled Geometries: Magnesium alloys have high fluidity, allowing for intricate, thin-walled, and near-net-shape parts with tight tolerances.

- High Strength-to-Weight Ratio: It offers high rigidity and is significantly stiffer than, or acts as a superior alternative to, high-performance plastics.

- Vibration & Sound Dampening: Ideal for housings and components that require excellent shock absorption and noise reduction.

- High-Speed Production: Magnesium has a lower heat capacity and lower viscosity than aluminum, allowing for faster injection and cooling times (shorter cycle times).

- EMI/RFI Shielding: Excellent for electronic enclosures requiring electromagnetic or radio-frequency interference shielding.

- Part Consolidation: Suitable for integrating multiple, complex components into a single, cohesive cast part.

What are the main advantages of magnesium die casting

Magnesium die casting offers significant advantages, primarily being the lightest structural metal— lighter than aluminum and lighter than steel—while providing excellent strength-to-weight ratios. It enables the production of complex, thin-walled, and near-net-shape parts with high dimensional stability. Key benefits include faster cycle times (up to faster than aluminum), longer tool life, excellent electromagnetic shielding, and 100% recyclability.

Key advantages of magnesium die casting include:

- Superior Lightweighting: As the lightest structural metal, it is ideal for weight-sensitive applications in automotive and electronics industries, reducing fuel consumption and enhancing portability.

- Fast Production Cycles: Magnesium has a lower heat capacity and shorter solidification time than aluminum, allowing for faster casting cycles and higher productivity.

- Exceptional Thin-Wall Capabilities: It allows for casting very thin, complex, and intricate components that are difficult to achieve with other metals.

- Reduced Tooling and Machining Costs: Due to lower affinity for iron and reduced thermal fatigue, die life is 2–4 times longer than aluminum casting. Furthermore, magnesium is easy to machine, reducing secondary processing costs.

- High Strength and Stability: It provides high dimensional stability, excellent impact resistance, and high component rigidity.

- Environmental and Cost Benefits: It is 100% recyclable and derived from abundant natural resources. The ability to cast to final net shapes reduces material waste.

- Enhanced Performance: Provides natural lubricity, good corrosion resistance (in high-purity alloys), and superior shielding against electromagnetic interference.