Recenze poskytovatelů služeb tlakového lití zinku pro automobilové díly

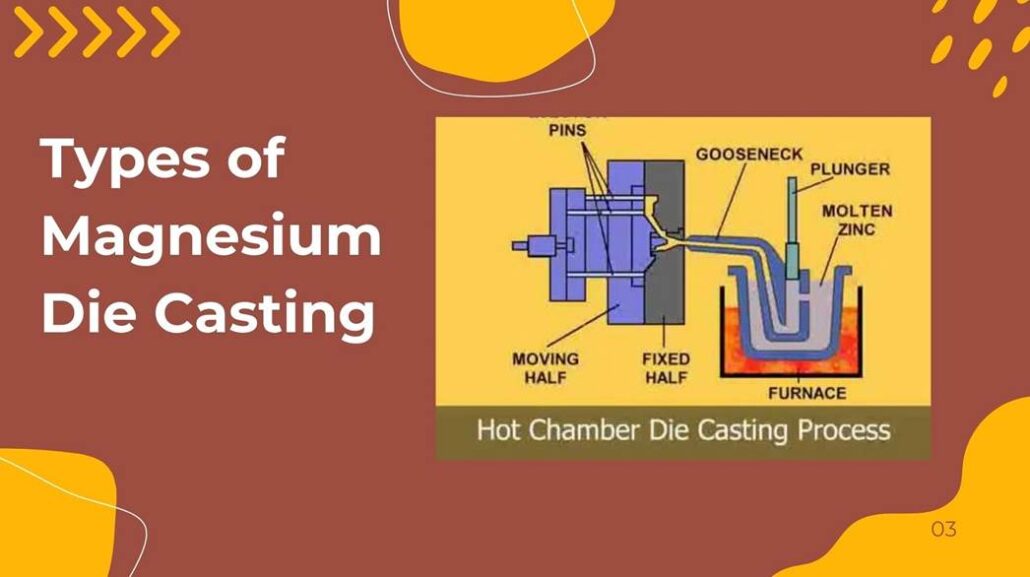

Tlakové lití zinkuIntroduction In the automotive industry, zinc has been a pillar raw material for die casting because it has a remarkable mixture of precision, strength, durability and cost-effectiveness. Automakers are also turning to the use of zinc alloys in those parts that demand tight tolerances, thin walls, high surface finishes, wear and corrosion resistance. This is used in common applications such as door handles, lock housings, seat belt mechanisms, gears, brackets, sensor housings and inner trim pieces. The technology is to inject high-pressure molten zinc into steel moulds, which can be of complex geometry and volumes with limited secondary machining. Chinese Mold Manufacturer has already dominated the world of zinc die casting by being able to offer tailor-made prices, facilities and the necessary certification, such as the IATF 16949, that is required by automobile suppliers. This paper summarizes the top zinc die casting service companies focusing on automotive parts, based on the capabilities of the companies, customer reviews and industry reputation. We are targeting the Chinese manufacturers, who are the major source of worldwide provision of low-priced yet high-quality motor parts. Key Advantages of Zinc Die Casting With the latest development of vehicles towards electrification and lightweighting, zinc die casting services are important to making dependable, high-performance components. The Zinc Die Casting Process Zinc die casting is a very efficient production process that is accurate in making complex metal parts that have superior surface finishes. It is especially well used in the auto industry with parts that have thin wall requirements, are high strength and have better plating compatibility. Just like aluminum die casting, zinc employs the hot-chamber process because it melts at a lower temperature (approximately 420 °C), providing it with short cycle times and extended tool life. Principles of the Zinc Die Casting Process Mold Preparation To ease ejection and temperature control, the steel die (mold) is sprayed with lubricant. The mold is made from strengthen material like steel that contains all the details of the automotive parts. Melting and Injection Zinc alloy (usually Zamak 3, 5 or ZA-8) is melted in a furnace that is connected to the machine. A gooseneck plunger is inserted into the molten metal and forces the final under high pressure (as much as 30 MPa) into the die cavity. Solidification The metal solidifies (a few seconds) in the water-cooled die, and the metal is solidified in its form of choice. Ejection The die is cast, and ejector pins push out the casting. The final shape of the product is solidified. Trimming and Finishing Flash (runners) is removed. The secondary processes, such as machining, plating or powder coating, are included. Trimming the unwanted part of the zinc automotive product is the final step. Why Zinc Die Casting is Superior in Automotive Applications Zinc alloys (i.e., Zamak 3, 5, and ZA-8) have distinct advantages compared to such alternatives as aluminum: High Quality Finish and Surface Finish Zinc fluidity allows adding thinner walls (down to 0.5mm) and finer details to minimize the post-processing. The automotive parts made from zinc have thinner walls and greater strength. Increased Strength and Impact Resistance Suited to components with safety-critical functions such as seat belt retractors and locks. The automakers preferred using these products. Extended Tool Life Due to the low melting point, zinc die casting products’ life is increased, and high-volume runs have reduced costs. Outstanding Plating Compatibility The process of zinc die casting is ideal for exterior or interior parts, as these are chrome-plated. Economical with Medium Volumes The automotive parts made by zinc diecasting use hot-chamber processes and have faster cycle times than aluminum. Zinc vs. Aluminum Die Casting Comparison for Automotive Parts Automotive parts could be made from zinc or aluminum. Here is the comparison table for the users to make the best decision according to their need of product. Features Zinc die casting Aluminum die casting Wall thickness Thinner (0.5-1.5mm) Thicker (2-5mm) Weight Higher High Melting point Low High Thermal conductivity High Low Corrosion resistance Higher Low Impact/strength High impact resistance Greater ductility Tool life Longer Shorter Cost Better for smaller parts Better for larger parts Applications Auto marine Power steering system Fuel system Engine system Automotive components Aerospace House appliances Medical automotive Best Die Casting Providers of Zinc Die Castings China (CNM Tech) This is a company that deals with zinc die casting and aluminum in the automotive parts industry in Dongguan, which is a die-casting hub. They have machines ranging from 120 to 1600 tons and in-house machining, deburring, plating, and powder coating. Strengths full service (one-stop), IATF 16949-certified, high concentration on automotive (e.g., brackets, housings). High-quality deburring provides parts without an accent. Customer Reviews Compliments on consistency, speedy delivery and competitive prices. Plated finishes are ideal for OEMs. Rating 4.8/5 -Dependable when using on mid-to-high volume automotive runs. GC Precision Mold Co., Ltd. GC, a zinc die casting manufacturer, was founded in 1999 in Dongguan, and it provides IATF 16949 certified zinc, aluminum and magnesium die cast. They cover the automotive, electronics and hardware industries. Strengths Large assortment of alloys, integration of CNC machining, and extreme care to tight tolerances. Verified in automotive components such as gears and housings. Customer Reviews Customer satisfaction rating (transparency, responsiveness, and consistency of quality) was high. Customers report about superior English communication. Rating 4.9/5 -Best selection of precision automotive parts. Sincere Tech (Dongguan Sincere Tech Co., Ltd.) Although its major operations are plastic injection and general die casting, Sincere Tech also offers zinc die casting services, together with machining and assembly. They refer to die cast of metal components, including the automobile. Strengths All-in-one services (design to assembly), ISO 9001:2015, 18 plus years of experience. DFM and fluent English assistance. Customer Reviews Favorable response towards project management and problem-solving. Excellent in problem-solving according to foreign clients. Rating 4.7/5: Strong on combined projects of zinc and plastic parts. PHB Inc. PHB is a hundred-year-old American company that deals with aluminum and zinc die casting. They work with large car manufacturers, making components such as drilling, milling