Moderne trender innen kaldkammerstøpeteknologi

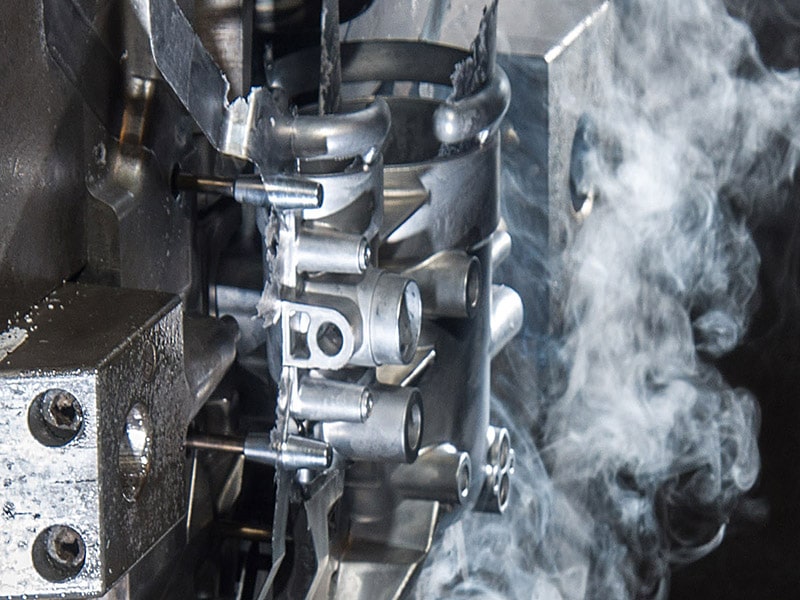

pressstøping, Produsent av støpegods, trykkstøpte delerCold Chamber Die Casting is a precision type of manufacturing technique applied in the manufacture of complicated metal components characterized by high levels of strength and precision. This process can best be used in metals having a high threshold of the melting point, like aluminum, brass, and copper alloys. Cold chamber die casting systems are not placed into molten metal like a hot chamber die casting system; instead, the metal is put into the cold chamber die casting machine by manually ladling metal into the cold chamber die casting machine after it is melted in another furnace. The arrangement wears less on the machine and uses alloys that are tougher. Among the important factors that make companies opt to use this method are the special cold chamber die casting advantages and disadvantages. It has top dimensional accuracy, smooth surface finishes, as well as long cycle times. Nevertheless, its strength and durability of the constituents are its favorites in the automotive, aerospace, and electronic markets. The difference between hot and cold chamber die casting is crucial to make the right choice of the process. Hot chamber die casting is more rapid and applied to metals of low-melting point, such as zinc, whereas the cold chamber die casting system is designed to handle higher temperatures and stronger metals. Manufacturers will also be able to manufacture long-lasting and reliable parts with this process that have a high degree of precision in their specifications. In the present article, we are going to discuss the principle of operation of cold chamber die casting, its main parts, the nature of the metal employed, and technological parameters of cold chamber die casting, including clamping force and cycle time. The cold chamber die casting advantages and disadvantages will also be considered to provide you with a full picture of this important manufacturing process. What is the Cold Chamber Die Casting? Cold Chamber Die Casting: A cold chamber die casting process is a metal casting process where molten metal is ladled either manually or automatically into a separate cold chamber outside the injection system. Thereafter, the metal is pushed with high pressure into a mold cavity, which causes the metal to cool and crystallize in the desired shape. It is usually applied to metal with a large melting point, like brass, aluminum, and copper alloys. The purpose of avoiding corrosion and thermal fatigue that can result in improper working of components of the injection system, unlike in the hot chamber die casting process, where the injection mechanism is suspended in molten metal, the cold chamber process keeps the injection facilities segregated. The application of the practice of the latter, i.e., Cold Chamber Die Casting, is especially advantageous, where the metals used would harm the components, contacting them. High pressure can be used in the injection process itself, and denser, stronger components with a brilliant surface finish and dimensional stability would be possible. Die Casting Process- Step by Step The object of the Cold Chamber Die Casting technique is to make highly accurate and hard metal parts that are frequently composed of alloys that have melt-points that are at high temperatures, such as aluminum and brass. Let us have a step-by-step breakdown of how it works: 1. The External Furnace is used to melt the Metal The process is similar to that of hot chamber casting except that the melting of metal is done in a separate furnace outside. This is required in that the molten metal in the cold chamber casting will cause a high level of heat to be experienced internally that cannot be handled. The metal is melted, after which it is able to be transferred into the casting machine. 2. Pouring the molten metal into the Shot Sleeve Thereafter, the molten metal is ladled into the shot sleeve in the die casting machine. This is manually done or arm-driven. The shot sleeve is a strong, resistant to heat tube into which the metal rests and is later injected. This should be taken very fast to prevent premature solidification. 3. Plunger forces the metal into the die. A steel plunger travels into the shot sleeve and presses the molten metal at high pressure in the die cavities. The force makes sure that the metal fills the mold even in any complicated pattern or with a very thin wall, and decreases the chances of any flaws, such as air pockets. 4. There is the Solidification of Metal within the Die When the mold is filled, the metal starts cooling and solidifying within the die. This solidification step is very important in coming up with a good and precise part. The cooling time is dependent on the part metal, part thickness, and die temperature. 5. The Brass Die and Ejector Pins Force-Out the Casting When the part has solidified, the clamping unit of the machine opens the die, and ejection pins force the casting out of the mold cavity. The portion is then moved to a cooler station or a trimming station. 6. Removal of Flash (Removal of Excess Metal) There is some over metal on the sides called flash that is around the edges of the casting where the halves of the die come together. This is then removed by mechanical trimming, grinding, or machining, depending on what the finish requires. This will prevent the final works from being below the intended shape and tolerance. 7. Die cycle reset and Lubrication The die is washed and greased before entering the next cycle in order to be of good quality and avoid sticking. When the oiling is done, the die is again clamped, and the machine is switched to reset for more cycles. 8. Quality Inspection and finishing This is a complete part that is checked to ensure quality defects do not exist, like cracks, shrinkage, or abnormalities on the surface. Depending on the end-use requirement of the part, it can be subjected to additional machining, surface treatment, or assembled (if required). Metals to be used in the