Die casting mould manufacturer

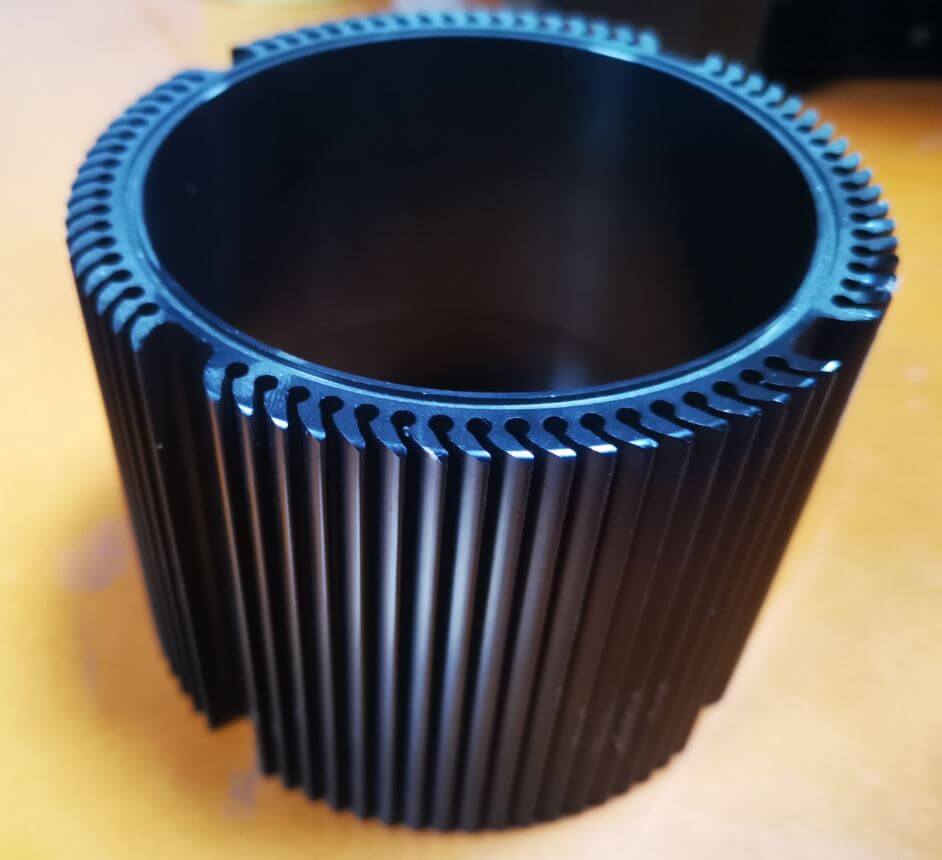

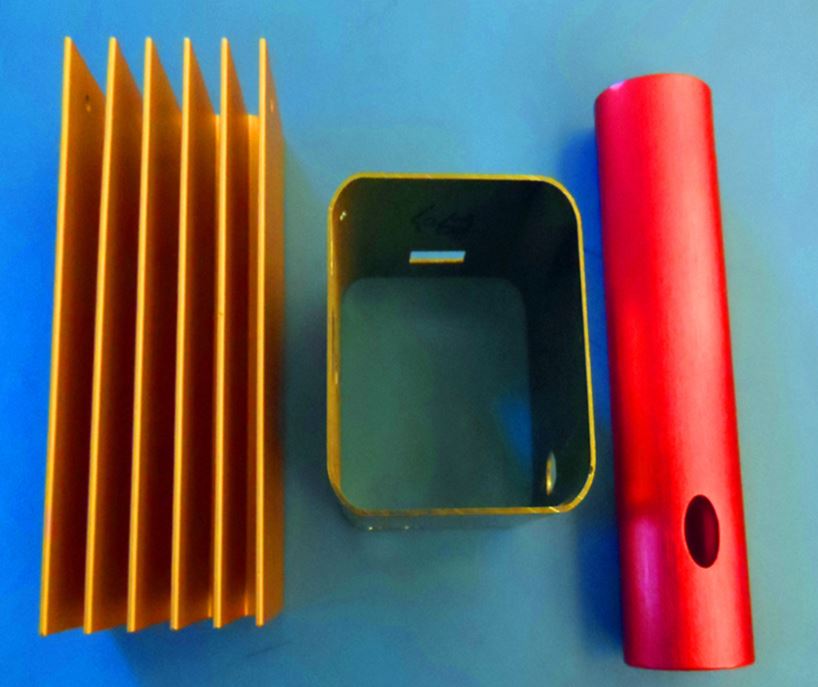

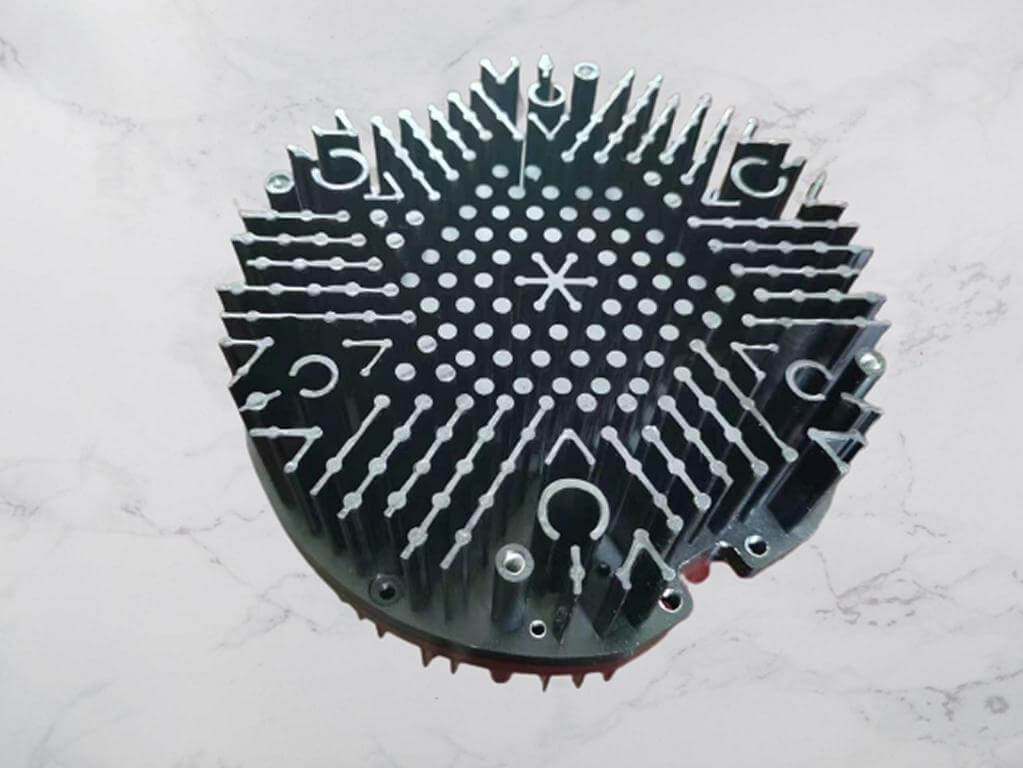

aluminum castingA Comprehensive Guide to Die Casting Mould Manufacturing by CNM TECH In the realm of manufacturing, die casting moulds stand as the unsung heroes behind the impeccable precision and efficiency of various products. At the heart of this intricate process lies the expertise of die casting mould manufacturers, with CNM TECH emerging as a prominent player in this dynamic field. Types of Die Casting Moulds Die casting moulds come in various types, each catering to specific manufacturing needs. Cold chamber die casting moulds, hot chamber die casting moulds, and multi-slide die casting moulds are the pillars of this industry. CNM TECH, a leading die casting mould manufacturer, specializes in crafting these moulds with unparalleled precision and reliability. Characteristics of a Reliable Die Casting Mould Manufacturer When it comes to choosing a die casting mould manufacturer, certain characteristics set the best apart from the rest. CNM TECH exemplifies these traits with its profound expertise in die casting technology, utilization of top-notch materials, precise tolerance levels, customizable solutions, and an unblemished reputation for delivering excellence. Key Considerations in Choosing a Die Casting Mould Manufacturer Choosing the right die casting mould manufacturer is a critical decision that can significantly impact the success of your manufacturing processes. Several key considerations should guide your decision-making process to ensure you partner with a reliable and competent manufacturer. Below are the essential factors to keep in mind: Industry Experience: Assess the manufacturer’s experience in the die casting industry. A company with a proven track record is more likely to have encountered various challenges and developed effective solutions. Technology and Equipment: Investigate the technology and equipment employed by the manufacturer. State-of-the-art machinery and advanced technology contribute to the precision and efficiency of the die casting process. Compliance with Industry Standards: Ensure that the manufacturer adheres to relevant industry standards and certifications. Compliance with standards such as ISO and other quality certifications is indicative of a commitment to producing high-quality moulds. Cost and Pricing Structure: While cost is a significant factor, it should not be the sole determinant. Consider the overall value offered, including quality, customization capabilities, and delivery timelines. Transparent pricing structures and no hidden costs are indicative of a trustworthy partner. Lead Times and Production Capacity: Evaluate the manufacturer’s production capacity and lead times. A reliable die casting mould manufacturer should be able to meet your production requirements within a reasonable timeframe while maintaining quality standards. Customization Capabilities: Assess the manufacturer’s ability to provide customized solutions. Different industries and applications may require unique specifications, and a manufacturer capable of tailoring their products to meet specific needs adds significant value. Reputation and Track Record: Research the manufacturer’s reputation in the industry. Customer reviews, testimonials, and references can provide insights into the company’s reliability, consistency, and commitment to customer satisfaction. Quality of Materials Used: The choice of materials significantly influences the durability and performance of die casting moulds. Ensure that the manufacturer uses high-quality materials suitable for your specific application. Communication and Collaboration: Effective communication is crucial for a successful partnership. Choose a manufacturer that values collaboration and maintains open lines of communication throughout the design, production, and delivery phases. After-Sales Support: Evaluate the level of after-sales support provided by the manufacturer. A company that offers ongoing support, maintenance, and assistance can help address any issues that may arise after the moulds are in operation. By carefully considering these key factors, you can make an informed decision when selecting a die casting mould manufacturer. CNM TECH, with its industry experience, cutting-edge technology, and commitment to quality, stands as an example of a reliable partner in the world of die casting mould manufacturing. The Die Casting Process Understanding the die casting process is vital to appreciate the significance of the moulds. CNM TECH’s expertise extends to every stage of die casting, from the initial design to the implementation of stringent quality control measures, ensuring that the final product meets the highest standards of precision and durability. Case Studies CNM TECH’s success stories serve as testaments to their commitment to excellence. Through in-depth case studies, we explore how CNM TECH’s die casting moulds have played pivotal roles in enhancing efficiency and product quality across diverse industries. The company’s portfolio demonstrates versatility and innovation in meeting unique manufacturing challenges. Emerging Trends in Die Casting Mould Manufacturing As technology evolves, so does the die casting mould manufacturing industry. CNM TECH stays at the forefront by embracing advancements in materials, integrating automation and Industry 4.0 practices, and incorporating sustainable manufacturing methods. The company’s forward-thinking approach ensures clients benefit from the latest innovations. Challenges in Die Casting Mould Manufacturing Even in the face of challenges, CNM TECH rises to the occasion. This section delves into common issues faced by die casting mould manufacturers and how CNM TECH navigates these challenges through innovative solutions. The company’s resilience and problem-solving capabilities underscore its commitment to customer satisfaction. Future Outlook for Die Casting Mould Manufacturing In a rapidly evolving landscape, the future of die casting mould manufacturing holds exciting possibilities. CNM TECH anticipates and prepares for upcoming technological advancements, contributing to the industry’s growth and offering clients cutting-edge solutions that meet the demands of tomorrow. Conclusion In conclusion, CNM TECH emerges as a trailblazer in the world of die casting mould manufacturing. Their commitment to precision, innovation, and customer satisfaction sets them apart. For businesses seeking reliability, efficiency, and a partner for the future, CNM TECH stands as the beacon of excellence in the intricate art of die casting mould production. Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making. With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions. We have been made many type of aluminum die casting, zinc die casting,