Hardware Die Casting: A Complete Guide to Modern Manufacturing

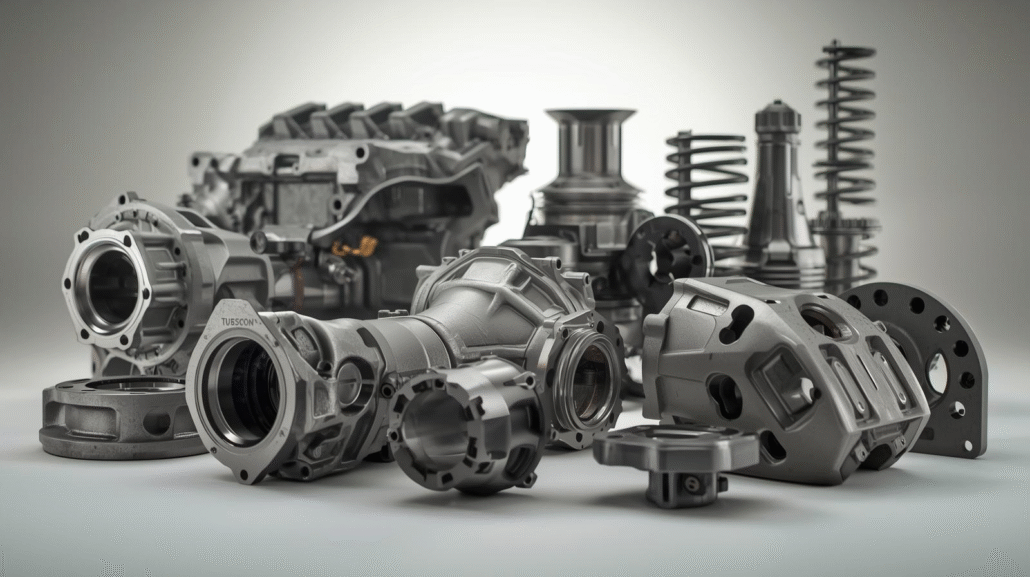

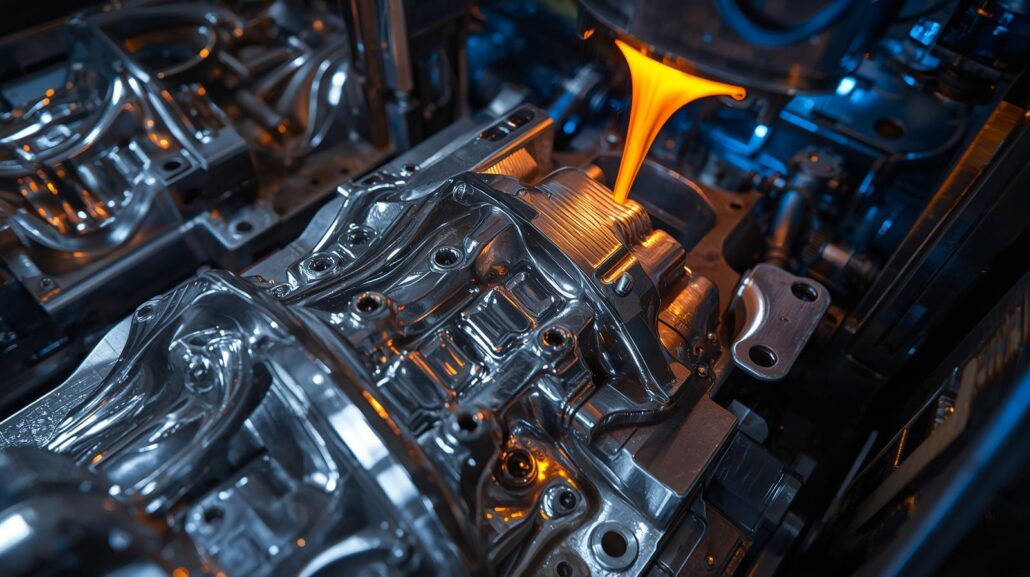

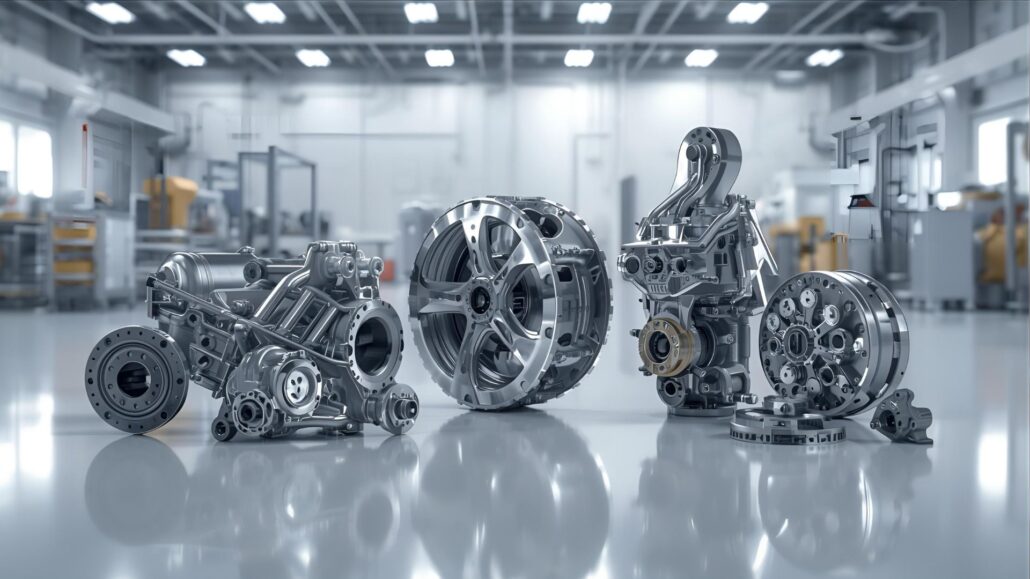

die castingThe modern competitive environment in the manufacturing industry has put industries under continuous pressure to manufacture hardware components that are robust, resilient, accurate, and economical. To attain these, firms use contemporary production methods that are quality and efficient. One of the most successful and popular processes is that of hardware die casting among them. Manufacturers are able to create hardware components that bring together complex detail with excellent strength by placing molten metal under high pressure into a mold made of steel. This process is used to produce both elements that have a smooth finish and even quality, as well as producing a significant number of elements at a reasonably low unit price. The relevance of hardware die casting is widespread in an array of industries. It is used in the automotive industry in the manufacture of light but strong components that result in fuel efficiency and safety. It can be used in electronics to make sustained housings, connectors and heat sinks. Precision parts are advantageous to aerospace companies in that they can withstand the harsh conditions, but the construction and furniture industries use them in their functional and decorative fittings. The article will be a complete investigation of the process of hardware die casting and its benefits, process, and materials. We shall also look at the position of the aluminum die casting hardware, the distinct advantages of the use of zinc die casting hardware and the increasing uses of the various parts of die casting hardware in the current industries. What is Hardware Die Casting? Hardware die casting is a specialized manufacturing method, which involves steel molds, otherwise molds, called dies, to form metal parts. This is done by melting metals like aluminum, zinc or magnesium and then forcing the molten metal into a die cavity at high pressure. After hardening of the metal, the mold is opened, and the component is forced out. The word hardware used here means minor yet vital parts such as hinges, brackets, handles, and locks, among other fittings. By casting them in die, the products are uniform, strong and cost-effective in contrast to other traditional methods of production like forging or machining. The Hardware Die Casting Process Design and Mold Preparation Hardware die casting- The die casting process starts by designing and preparing the mold, or die. A mold is designed by engineers using high-quality steel, which is hard enough to endure a higher number of molten metal injection cycles. The two halves of the mold are then molded and assembled to create a hollow into which the part will be shaped. To be efficient, the die will have inbuilt cooling channels to maintain its temperature and ejector pins, which will enable it to be easily released once it has solidified. Melting the Metal Once the mold is ready, the chosen metal is melted in a furnace at well-monitored temperatures. Aluminum and zinc are the most used, and it is important to maintain the appropriate molten state. The constant temperature enables the flowing molten material to fill the mold without forming defects and air bubbles. Injection into the Die After getting the metal to the correct molten state, it is forced into the die cavity with extremely high pressure that may range between 1500 and 25000 psi, depending on the material to be used and the intricacy of the design. It is a high-pressure injection method, which guarantees that all the sections of the mold are filled to the last detail, and the outcome is extremely precise. Cooling and Solidification Immediately the molten metal gets into the mold, it starts cooling and hardening. This process has to be well regulated since either rapid or slow cooling can lead to changes in the quality of the end product in terms of strength and precision. When an appropriate cooling cycle is maintained, the hardware components will be powerful and dimensionally accurate. Ejection and Finishing When the part is solid, the mold is opened, and the component is literally ejected by ejector pins. This is where the product is shaped, but it has excess material commonly referred to as a flash. This is removed and the portion can be subjected to further finishing processes of polishing, anodizing or coating to enhance its looks and workability. The cycle can be subsequently repeated continuously, and the manufacturers can manufacture huge numbers of the same type of die casting hardware parts with very high efficiency. Benefits of Hardware Die Casting Precision and Accuracy Among the most powerful positive aspects of the hardware die casting is the high precision that the process can provide. Complicated designs that are tightly tolerated can be generated in the process, and this can avoid further machining or even completely do away with it. This precision means that all the components fit in their use, be it in a vehicle, an electronic product, or building hardware. The manufacturers also like the fact that they are able to create complex shapes in the same process instead of using various manufacturing processes. Strength and Durability Die-cast metals are recognized to have a strong mechanical ability and outstanding endurance. Hardware components manufactured under the process of hardware die casting are capable of sustaining high weight, repeated application and subject to wear and tear without their functionality being affected. This is the reason why these parts tend to be applied in the most reliable industries, such as automotive and aerospace. Its durability also implies that there is a reduced need to replace products, and this is a value addition to the manufacturer and the end-users as well. Economical when dealing with large quantities The casting process is very cheap when mass production has to be done after the die has been produced. Firms can manufacture thousands or millions of parts of the same type with a very small variation. This capability to produce on a large scale and at a low cost per unit is among the factors that make hardware die casting more desirable compared to other