I 10 principali produttori di prodotti in alluminio in Cina e negli Stati Uniti

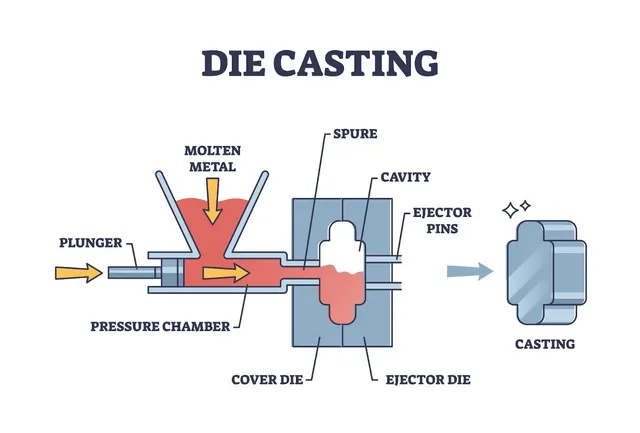

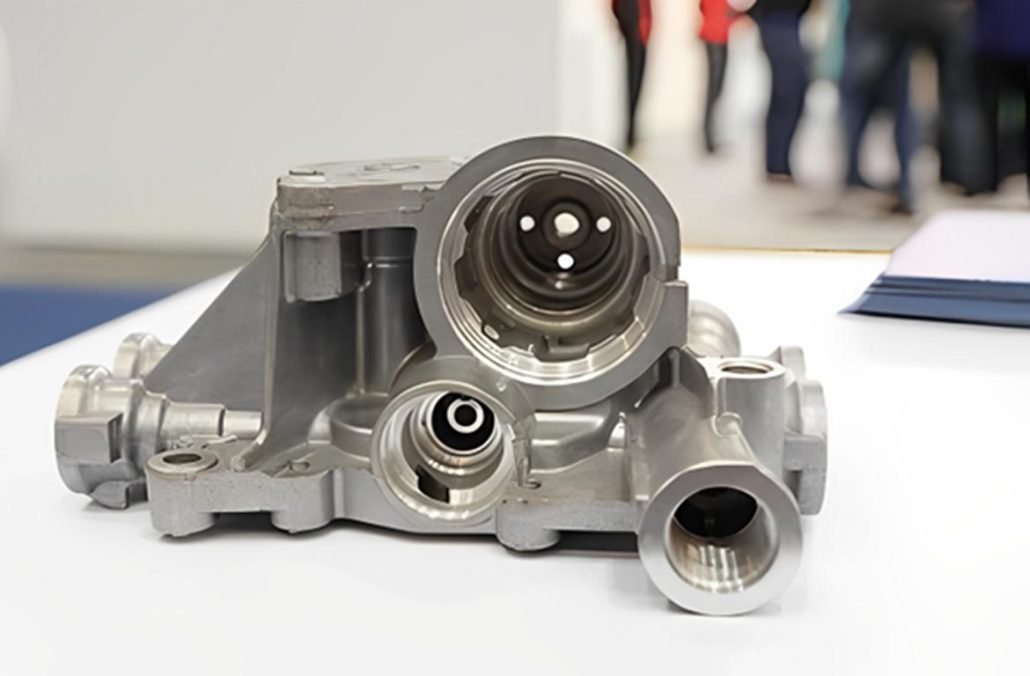

colata di alluminioAluminum Product Manufacturers are crucial in the industries of automotive, aerospace, electronics, packaging, etc. Therefore, many top-tier aluminum product manufacturers have risen in China and the USA due to the growing demand for lightweight, durable, and recyclable materials. Innovative, with high-quality standards, and dedicated to sustainability, these companies are known for their innovation. Other leading metal manufacturing countries include China and the USA, where the most important players have been developing new methods of manufacturing aluminum. Some of the companies that have aluminum die casting, CNC machining, and precision molding’ are CNM Tech Co., Ltd., GC Precision Mold Co., Ltd., and Sincere Tech in China. With the industry demanding strict quality for high-performance aluminum components, these firms focus on various industries.Major manufacturers such as United Aluminum Corporation, Arconic Corporation, Kaiser Aluminum, and JW Aluminum have stood out as pioneers in aluminum rolling, extrusion, and fabrication in the USA. These companies operate in the field of cutting-edge aluminum solutions for aerospace, automotive, and industrial applications. This article presents 10 of the top aluminum product manufacturers based on innovation, sustainability, and excellent quality of their wares in different worlds 1. CNM Tech Co., Ltd. Year of Establishment: 20+Number of Employees: 100-200Business Type: CNM Tech is focused on aluminum, magnesium, and zinc die casting, CNC machining, surface finishing, and assembly. Website and Contact Website: https://www.thediecasting.com/Contact: +86 13045898002Email: sales@thediecasting.comAddress: Factory Address: Rm 101, No.40, Donghu Road, Jinglian, Qiaotou town, Dongguan city, Guangdong Province, China. 523520. Company Profile Founded over 20 years ago, CNM Tech Co., Ltd., is one of the leading Chinese manufacturers of die-casting solutions. The company is based in Dongguan, China, where it provides a thorough assortment of services including aluminum, magnesium, and zinc die casting, precision CNC machining, surface finishing, and assembly. They have expertise in automobile, electronics, aerospace, and hospitality appliance markets, to name a few. Their Quality Commitments CNM Tech is dedicated to providing high-quality, low-cost products while abiding by extremely tight quality control standards under the auspices of ISO 9001. They take a customer-centric approach, providing personalized services from the time of initial consultation and beyond, from availability to post-production support services to maintain long-term partnerships all over the world. Why Choose CNM Casting? As a name known in the die-casting industry, CNM Tech specializes in providing high-quality manufacturing solutions with advanced technology, and a customer-oriented approach. These are reasons why CNM Tech is your number one reason. The choice of CNM Tech guarantees a reliable manufacturing partner that implements innovations and focuses on quality and customer success. 2. GC Precision Mold Co., Ltd. Year of Establishment: 1999Number of Employees: 100-200Business Type: Serving industries such as the auto, aero, and electronics industries, the company has gained international market trust. Website and Contact: Website: https://aludiecasting.com/Contact: +86 131 4886 5556Email: info@aludiecasting.comAddress: Factory Address 1: No. 30 Huan Zhen Rd, Qi Shi Town, Dongguan City, Guangdong Province China, 523516 Company Profile Founded in 1999, GC Precision Mold Co., Ltd. is a global leader in high-quality aluminum die casting and nonferrous metal products. It has two special properties plants located in Dongguan, China, and offers services including high-pressure die casting, sand casting, and forging. As a result of over two decades of experience, the company delivers precision, consistent quality, and flexible material offerings to a variety of industries such as automotive, aerospace, and electronics. Both client satisfaction and GC Precision Mold commit to honorable words and behavior in providing the best product. Their Quality Commitments Its various certificates are proof that GC Precision Mold Co., Ltd. adheres to the highest standards of quality and operational excellence. The company possesses certificates from ISO 9001 on Quality Management Systems, which demonstrates the company’s ability to provide the product according to customer requirements at all stages and to enhance quality systematically. Why Choose GC Precision Mold Co., Ltd.? When you are choosing a company in pursuit of top-grade die casting and metal products, there are many benefits to choosing GC Precision Mold Co., Ltd. 3. Sincere Tech Year of Establishment: 2005Number of Employees: 100-200Business Type: Sincere Tech, is a leading Chinese manufacturer of custom plastic injection molds and aluminum product manufacturer. Website and Contact Website: https://plas.co/Phone: +86 135 30801277Email: steve@sincere-tech.comAddress: Rm101, N041, Donghu road, JingLian cun, qiaotou town, Donggguan City, Guangdong Province, China. 523000. Company Profile We are Sincere Tech, a world-renowned leading Chinese manufacturer of custom plastic injection molds and aluminum die-casting solution Injection Molding services. The company was founded in 2005 and has successfully established itself as a professional and highly reliable, high-precision, cost-effective, and high-quality production service provider to the world. From automotive, medical, electronics, home appliances, food packaging, cosmetics, etc. industries, Sincere Tech is equipped with state-of-the-art technology, expert engineering, and strict quality control. Their Quality Commitments ISO 9001:2015 and QS 9000:2015 standards are the only hallmarks we take seriously to maintain high-quality standards for our products and services since Sincere Tech. Their investment in advanced technologies, such as 5-axis CNC machines and FANUC systems, underscores their commitment to precision and efficiency. Confidentiality is also a company standard, promising Non-Disclosure Agreements (NDAs) for the protection of client projects. Why Choose Sincere Tech? 4. United Aluminum Corporation Year of Establishment: 1981Number of Employees: 1000+Business Type: Custom Rolled® Aluminum Coil Manufacturer and Supplier, Precision Slitting, Annealing, Surface Finishing. Website and Contact Website: https://unitedaluminum.com/Phone: 800-243-2515 / 203-239-5881Email: Sales@UnitedAluminum.comAddress: 100 United Drive, PO Box 215 North Haven, CT 06473 Company Profile United Aluminum (founded in 1891) is a leading supplier of Custom Rolled® Aluminum Coil to industries such as automotive, aerospace, medical, and packaging. These alloys are 3003, 2024, and 7075 and these guys offer precision slitting, annealing, and surface finishing. They have advanced facilities in which they produce high quality at very cheap rates. Additionally, United Aluminum supplies an Aluminum Coil Calculator resource to help its clients make educated choices. Their Quality Commitments Commitment to Quality and Customer Satisfaction a very high standard of quality is maintained by United Aluminum and the company is ISO 9001:2015 certified. Other than this, they concentrate