Top Automotive die casting companies in China and the world

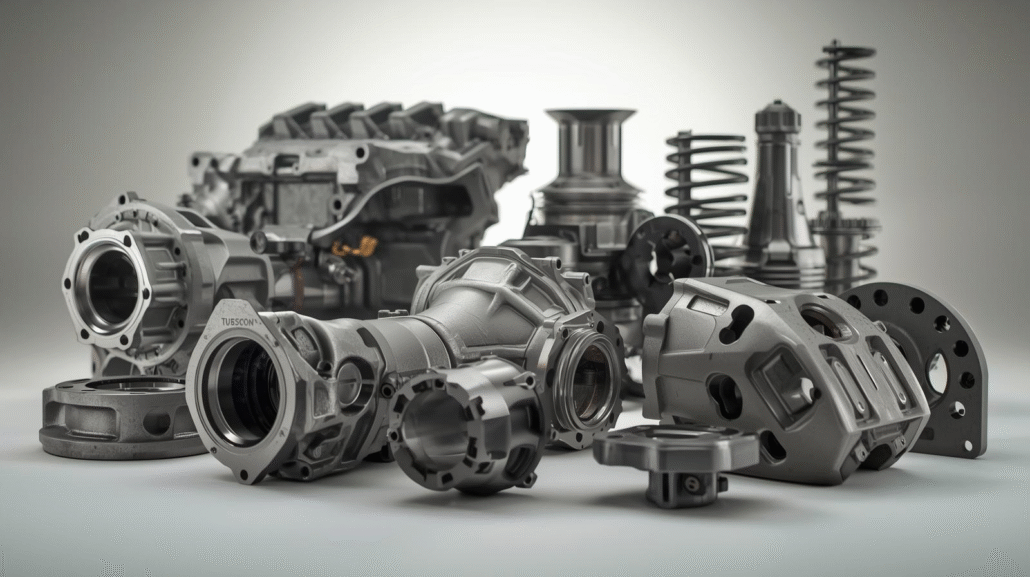

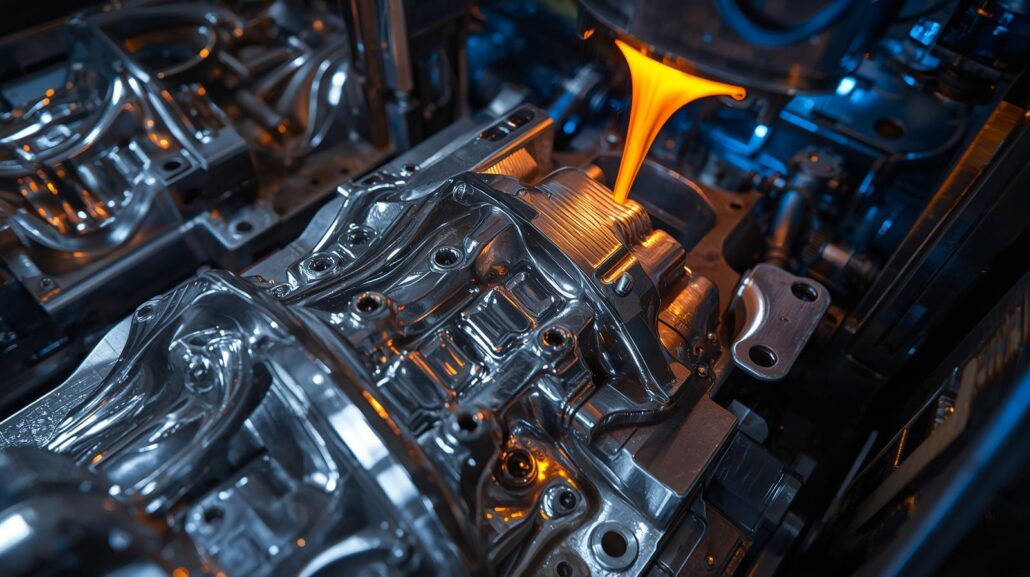

aluminum die casting, die casting companies, die casting company, Die Casting ManufacturerAluminum die casting is one of the most dependable and cost effective manufacturing processes in the contemporary industry. It is the process of high pressure injection of high temperature melted aluminum into an accurate mold to create powerful, lightweight as well as dimensionally precise parts. It is particularly useful in the production of highly complex shapes with high surface finishes, and thus it is a favored process in the automotive, aerospace, electronics, consumer products, and industrial machinery industries. The aluminum die casting has been on a high demand in the past years. The tendency of the world towards electric cars, lightweight constructions, and energy efficiency has put the aluminum alloys on the frontline of innovation. Manufacturers have now developed high-tech components like engine blocks, transmission houses, battery enclosures and heat sinks that are both durable and lightweight. Recyclability and resistance to corrosion make aluminum also helpful in the world-wide tendencies to produce sustainable and ecologically friendly. Two of the major aluminum die casting hubs are the United States of America and China. Campanies in the United States are known to be innovative, have high standards in quality, and use high levels of automation and can be considered as a good investment in high precision industries. Conversely, Chinese manufacturers have gained a lot of competitiveness over the world market, have provided a cost effective solution, high production capacity and more advanced technologies. This paper will discuss some of the most successful aluminum die casting industries in the USA and China, their strengths, abilities and the factors that make them the most reliable partners that businesses across the world as their preferred suppliers in the manufacturing industry. What is Automotive Die Casting? Die casting is a production process whereby molten metal, usually aluminum, magnesium, or zinc, is forced under great pressure into a mold that has an open space. This enables mass production of high-strength components of complex functions and with good surface finish and dimensional accuracy. Die casting in the automotive industry allows the production of components which are: The use of die casting has revolutionized the construction of contemporary vehicles whereby one can save weight and still manage to perform at the same time. The demand has contributed to the high rate of development of the major Automotive die casting firms in China, Europe, America and Japan. Why China is the leader in Automotive Die Casting China has some of the largest in the world of manufacturers of Automotive die castings because of its: Such a set of strengths has enabled Chinese auto-motive die casting firms to be the powerhouses not only in the local market but also internationally in the supply chain. CNM Tech Diecasting Company is a leading producer of superior aluminum die-cast products. They offer several sectors such as automotive, electronics and telecommunication with precision-engineered components that are aimed at maintaining the highest quality standards. They can produce light and strong parts utilizing their advanced production processes such as high-pressure die casting and CNC machining. The Diecasting Company believes in the power of constant innovation and therefore, it invests in modern machinery, automated production lines and more importantly quality control systems that help to deliver the same results at all times. Both OEMs and Tier-1 suppliers are also in their global client base, and therefore, they are a reliable partner in meet complex and large-volume production needs. Website: https://www.thediecasting.com/ Why Choose Them The Diecasting Company is preferred by businesses because it is focused on quality, precision, and innovation. Their application of state-of-the-art die casting technologies, strong quality control, and delivery on time makes sure that their clients get the components that could meet international standards and make them their favorite choice when it comes to automotive OEMs and manufacturers that want to find a reliable die-cast solutions provider. Industries Served Sincere Tech Sincere Tech is one of the producers of high-precise molds in plastic injection and die casts. They have a background in designing mold, prototyping, and manufacturing of the final product which provides a one-stop solution to their customers all over the world. They use computerized CAD/CAM software and automated machining so that all the molds manufactured are very accurate. Plastic Mold can be credited with years of experience in serving the needs of automotive, consumer electronics and medical device industries with the capacity of delivering complex molds with efficiency. They stand out in their innovation, quality control, and speed in delivery, thus making them a trusted supplier of companies that would like to have a personalized mold solution. Website: https://www.plasticmold.net/ Why Choose Them Plastic Mold is selected due to their complete mould making systems, technical skills and capability to fit into constrained production time. Their superior quality molds minimize errors, enhance productivity and aids clients to have accurate and dependable die-cast or injection-molded products. Industries Served GC Precision Mould GC Precision Mould is a producer of die casting in China which provides aluminum, zinc, and magnesium die casts. They have reputations of manufacturing high quality, cost effective, and lightweight parts in the automotive, electronic and lighting sectors. They have the abilities of high-pressure die casting, CNC machining and secondary finishing operations. Alu Diecasting is focused on accuracy, longevity and productivity. They are always up to the international standards with the use of modern facilities, automated lines, and skilled engineers. They cater to customers both locally as well as internationally such as OEMs and Tier-1 suppliers, and are positioned as a top Chinese manufacturer of die castings as an automotive industry. Website: https://aludiecasting.com/ Why Choose Them They are using Alu Diecasting as they offer a combination of competitive prices, high-quality standards, and technology. They have a track record of various alloys, precision machining and on time production which maintains dependable, long life, and lightweight parts that satisfy the demands of the world automotive industry. Industries Served Get It Made Get It Made is a producer of CNC machining, 3D printing, die casting, and metal forming based in UK. They support both prototyping and low-volume production,